Wear-resistant bainite cast steel liner plate and manufacture process thereof

A manufacturing method, bainite technology, applied in the direction of manufacturing tools, casting molding equipment, molding machines, etc., can solve the problems of quenching medium easy to pollute the environment, unstable quality, high production cost, etc., to improve the performance of lining board and production process Simple and easy to implement, the effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

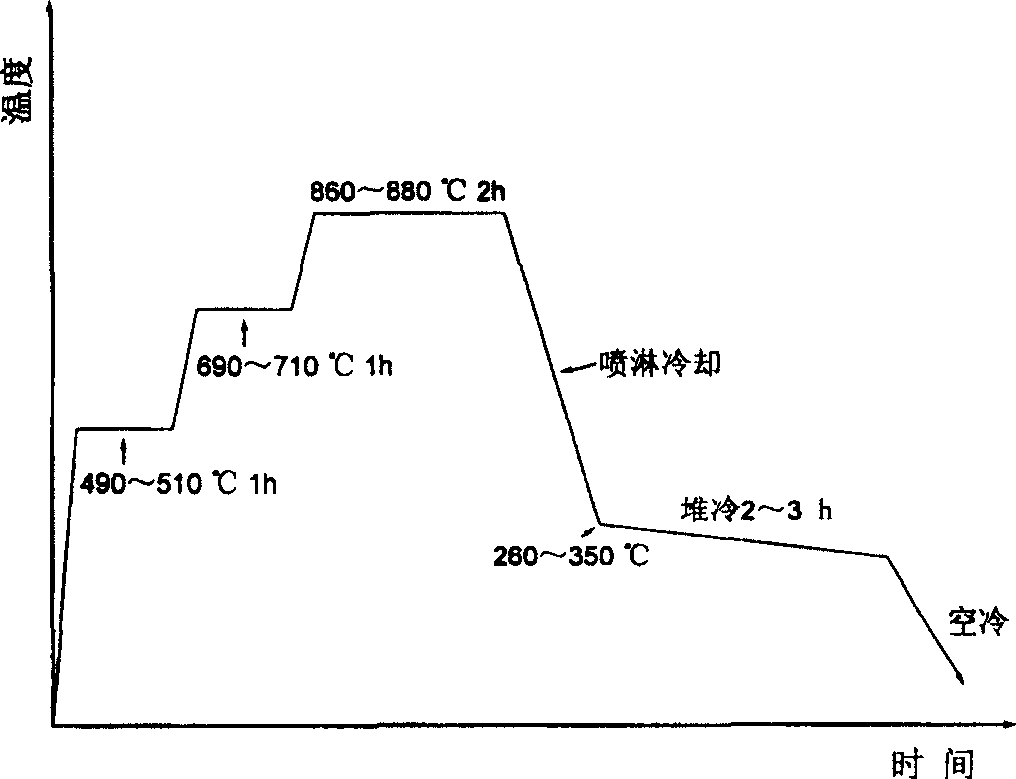

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The composition mass ratio (wt.%) of cast steel liner plate in the present invention is: C: 0.45~0.55%; Si: 1.6~2.0%; Mn: 2.8~3.3%; P≤0.06%; S≤0.04%; The amount is Fe.

[0026] Put the raw materials after the chemical composition of Examples 1-4 listed in the following table into the intermediate frequency induction furnace for smelting. The electric furnace uses an acidic furnace lining, and uses quartz sand as a slagging agent. Add Si and Mn alloy elements 5 minutes before the furnace is released. , control the temperature of the molten steel at 1530°C, and the final deoxidation is the deoxidation in the aluminum wire ladle:

[0027]

[0028] (1) The melted molten steel is cast into shape according to the following method: vacuum solid mold casting (EPC). Specifically: first bond the lining boards into strings, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com