PVC twisted pipe production process

A production process and winding pipe technology, applied in the field of PVC winding pipe production technology, can solve the problems that restrict the popularization and application of PVC winding pipes, the rigidity of PVC winding pipe rings cannot be broken, and deviate from design requirements, etc., to achieve wide application, stress relief, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

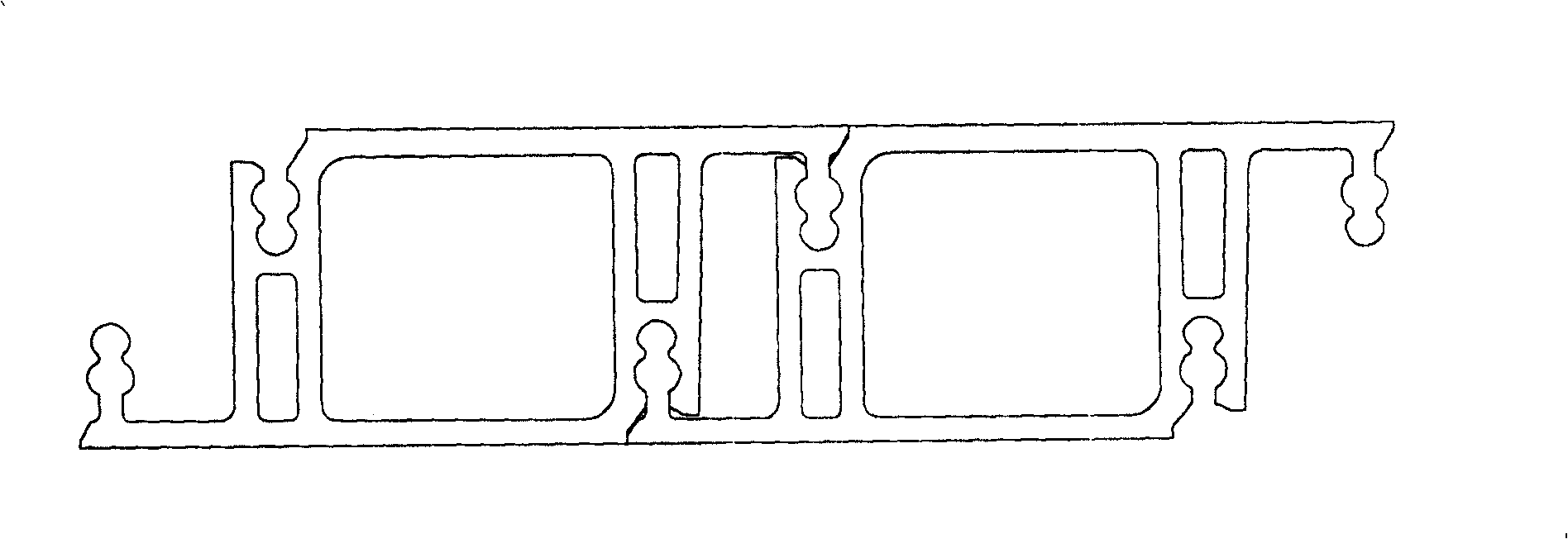

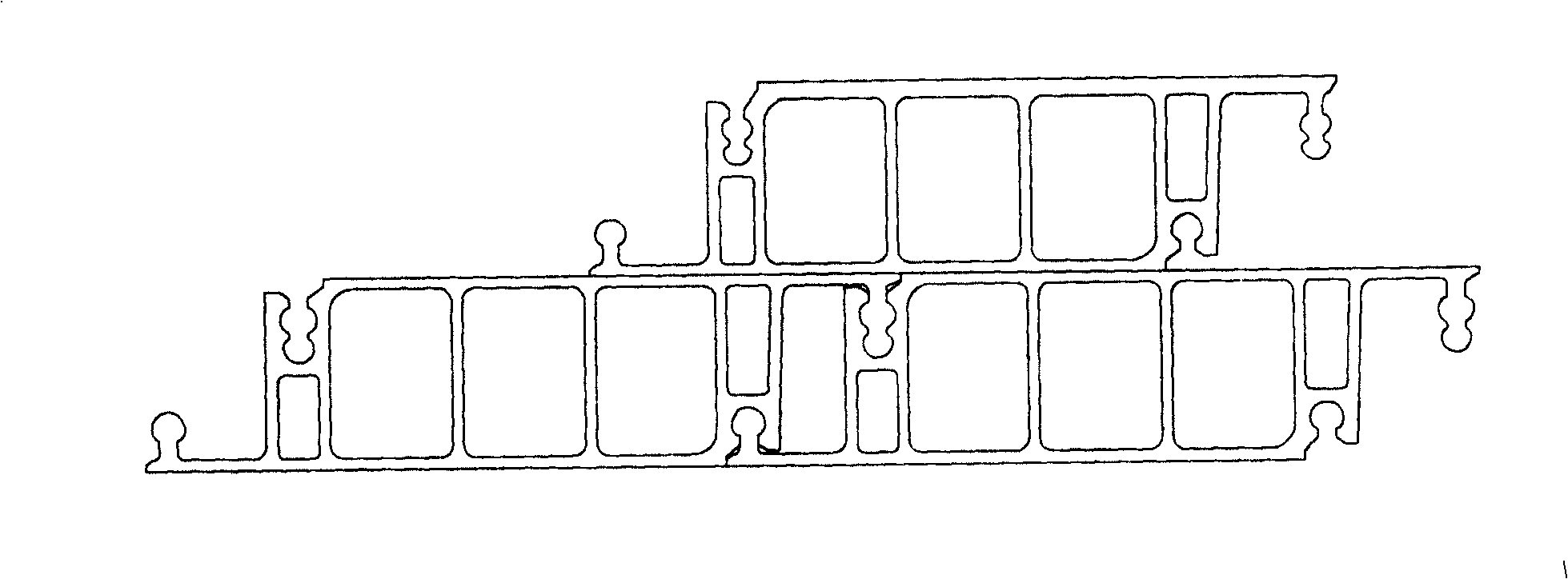

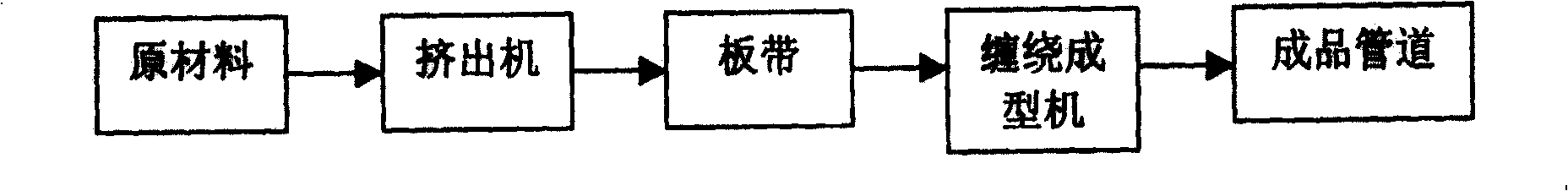

[0027] Production process such as image 3 As shown, first the PVC material is extruded through the extruder with a cross-section such as Figure 1-2 For the PVC strip 2 shown, heat the PVC strip 2 through the tunnel heater 3 for about 2 minutes, so that the temperature of the strip 2 reaches 85°C, and keep the temperature and wind it with the winding molding machine 5 to form a PVC pipe 1.

Embodiment 2

[0029] Production process such as Figure 4As shown, first the PVC material is extruded through the extruder with a cross-section such as Picture 1-1 As shown in the PVC strip 2, the PVC strip 2 is wound into a PVC pipe 1 by a winding forming machine 5. After the PVC winding pipe 1 is wound and formed, the pipe 1 is heated by the tunnel heater 4 for about 2 minutes, so that the pipe 1 When the body temperature reaches 40°C, part of the internal stress can be eliminated and the ring stiffness of the pipeline can be improved.

Embodiment 3

[0031] Production process such as Figure 4 As shown, first the PVC material is extruded through the extruder with a cross-section such as Picture 1-1 As shown in the PVC strip 2, the PVC strip 2 is wound into a PVC pipe 1 by a winding forming machine 5. After the PVC winding pipe 1 is wound and formed, the pipe 1 is heated for about 3 minutes by the tunnel heater 4, so that the pipe 1 The temperature of the body reaches 75°C to eliminate its internal stress and improve the ring stiffness of the pipe.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap