Satellite acceptor shell and forming method

A receiver and molding method technology, which is applied in the field of satellite receivers, can solve the problems of O-ring deformation, rainwater infiltration, failure to achieve waterproof function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

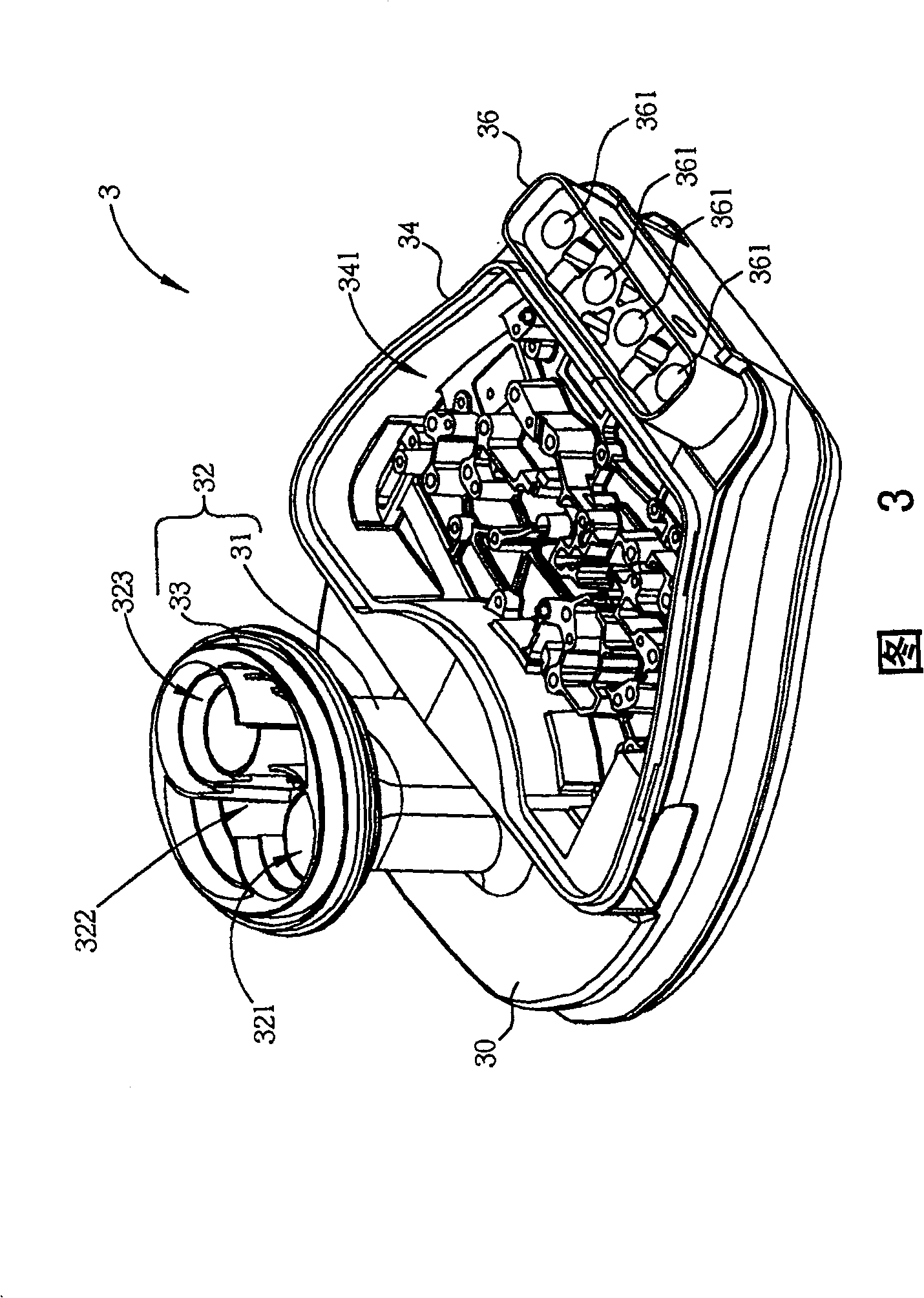

[0014] Please refer to FIG. 3; FIG. 3 is a schematic diagram of a satellite receiver 3 of the present invention. The satellite receiver 3 includes a main body 30 , a signal feed-in portion 32 , a first circuit board accommodating portion 34 and a signal output portion 36 . The signal feeding part 32 includes a cylinder 31 , an opening 33 and a plurality of signal receiving ends 321 , 322 , 323 for receiving satellite signals. The first circuit board accommodating portion 34 includes a first groove 341 for accommodating a circuit board. The signal output unit 36 includes a plurality of signal output terminals 361 . The satellite receiver 3 of the present invention is integrally formed without assembling gaps, so that the assembling gaps can avoid affecting the quality of receiving satellite signals and avoid rainwater penetration.

[0015] Please refer to FIG. 4 to FIG. 6; FIG. 4 to FIG. 6 are a side view, a top view and a bottom view of the satellite receiver 3, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com