Stretchable clothing

A stretchable and clothing technology, applied in the field of stretchable clothing, can solve the problems of elastic silk being easily cut off, dyed mottled, lack of stretchability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

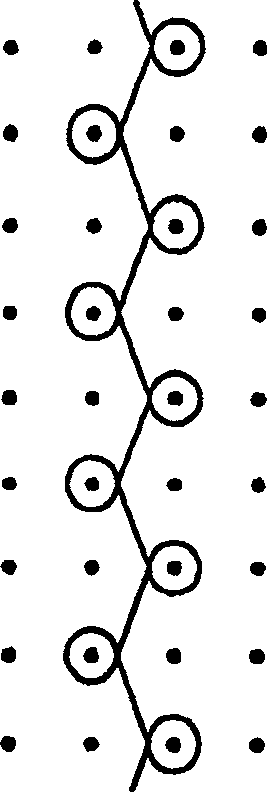

[0075] Use a Raschel warp knitting machine with a weaving width of 130 inches (330.2cm), use 2 reeds, use a denier of 44dtex, 34 filaments of matte nylon yarn as non-elastic yarn, and a denier of 44dtex polyurethane transparent yarn (Transparent yarn) is elastic yarn, so that the two are woven together like figure 2 All shown are 1×1 tricot tissues with closed coils. Because the total number is more than 3600, although the processing width of the knitted fabric is generally about 160 cm, it is set to 130 cm (about 70 wales / inch) in this example. As a high-density knitted structure, Narrow width processing is carried out as far as possible. Moreover, the yarn feeding amount of nylon yarn should be set to below 80 cm / gram in common knitted fabrics, and in the present embodiment, it is set to 100 cm / gram, and the yarn feeding amount of polyurethane yarn should be set at 100 cm / gram in common knitted fabrics. It should be set to 60cm / dak or less in the material, and in this embo...

Embodiment 2

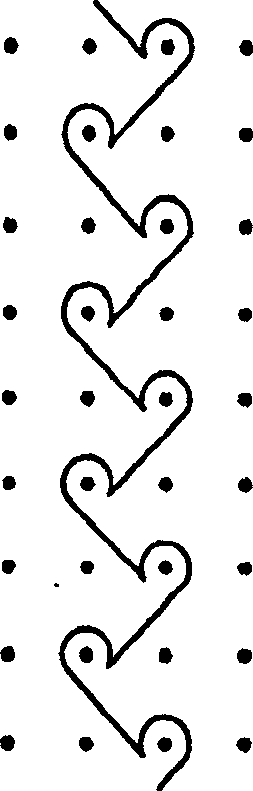

[0077] Using the same warp knitting machine as used in Example 1, with 2 reeds, the same nylon yarn used in Example 1 was used as the non-elastic yarn, and the polyurethane transparent yarn with a fineness of 78 dtex was used as the elastic yarn, Make the two go hand in hand to weave as image 3 The shown non-elastic yarn 1 is a closed coil, and the elastic yarn 2 is a 1×1 tricot structure of an open coil, which is processed into the same narrow width as in Example 1. Moreover, the yarn feeding amount of nylon yarn is set to be below 80 cm / dak in common knitted fabrics, and in this embodiment, it is set to 110 cm / dak, and the yarn feeding amount of polyurethane yarn is set to 110 cm / dak in common knitted fabrics. It is set at 80 cm / gram or less, and in this embodiment, it is set at 100 cm / gram. The woven knitted fabric was subjected to the same heat setting as in Example 1. The resulting knitted fabric has a neat and attractive appearance.

Embodiment 3

[0079] Using the same warp knitting machine as that used in Example 1, with 2 reeds, the nylon yarn of 33dtex is used for the non-elastic yarn, and the polyurethane transparent yarn of 44dtex is used for the elastic yarn. Figure 4 All shown are open loops and closed loops alternately, but in the same knitting needle, the elastic yarn 2 is a closed loop relative to the open loop of the non-elastic yarn 1, and the elastic yarn 2 is open compared to the closed loop of the non-elastic yarn 1 The loops are thus combined to weave a 1×1 tricot weave and processed into a narrow width of 130 cm. Moreover, the yarn feeding amount of nylon yarn is set to be below 80 cm / dak in common knitted fabrics, and in this embodiment, it is set to 110 cm / dak, and the yarn feeding amount of polyurethane yarn is set to 110 cm / dak in common knitted fabrics. It is set at 60 cm / gram or less, and in this embodiment, it is set at 95 cm / gram. The woven knitted fabric was subjected to the same heat setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com