Expansion pipe device for oilfield well completion

A technology of expanding pipe and expanding head, applied in wellbore/well components, heat treatment process control, heat treatment equipment, etc., can solve the problems of large self-weight and special hanging force of pipe string, complex supporting technology and high cost, and achieve comprehensive benefits Outstanding, wide application prospect, small expansion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

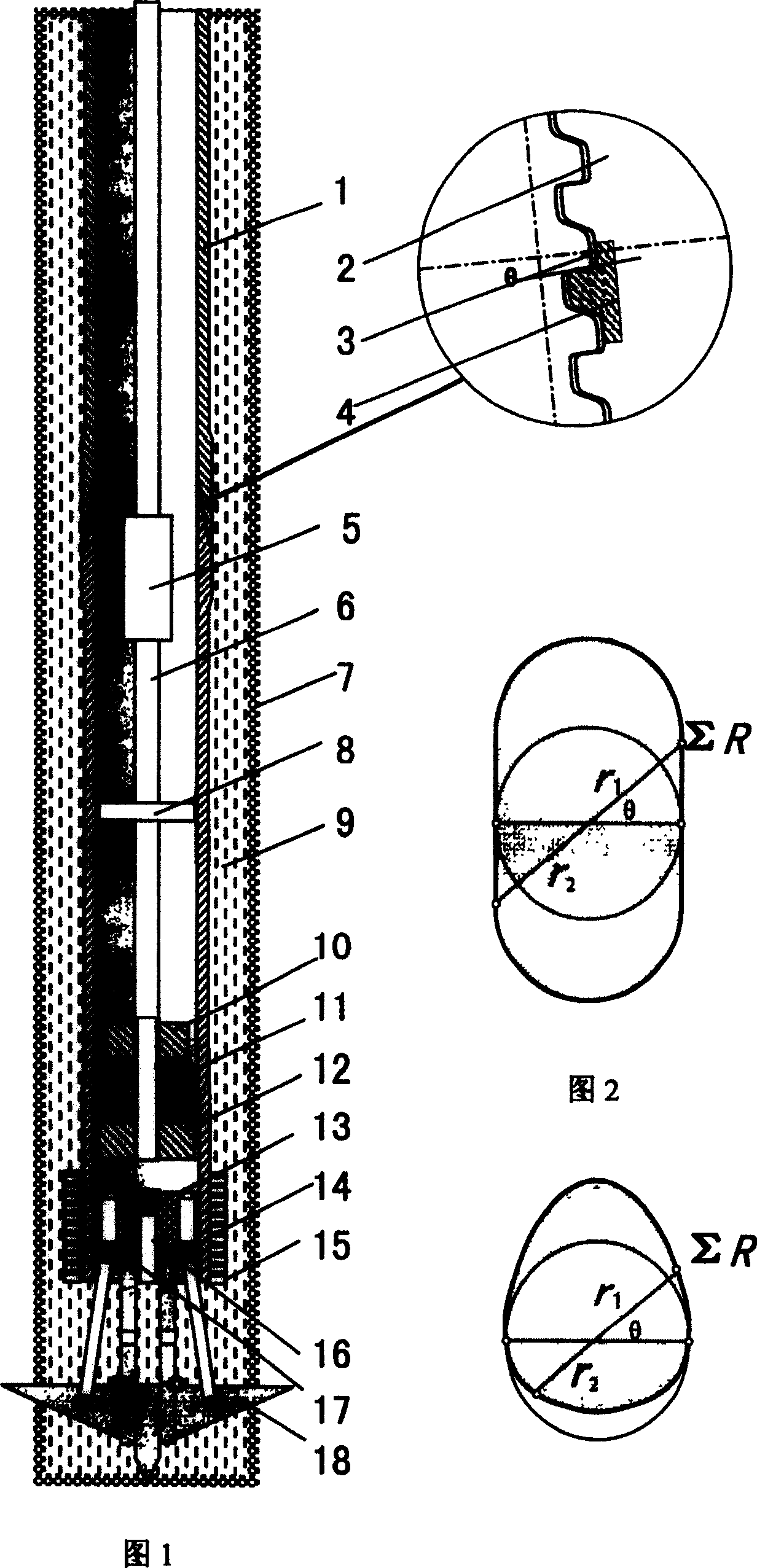

[0028] In conjunction with the accompanying drawings, the specific implementation process of the present invention is further described.

[0029] As shown in the figure, the expansion pipe device of the present invention consists of an expansion pipe 1, a connecting internal thread 2, a connecting external thread 3, an inlaid plastic ring 4, a hoisting pipe collar 5, a hoisting pipe 6, a drilling hole 7, a centralizer 8, and a filling mud 9. The positioning nut 10, the swing expansion head 11, the fixed nut 12, the sealing rubber plug 13, the sealing packing 14, the shape memory alloy ring 15, the columnar bottom cover 16, the auxiliary cylinder 17 and the fixed spear 18 are composed.

[0030] The expansion pipe 1 can be made as a seamless pipe or a pipe with a seam, and the expansion pipe 1 is connected to each other by means of its lower connecting internal thread 2 and upper end connecting external thread 3 . Inlaid plastic ring 4 is press-fitted on the midpoint of the expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com