Intellectualized lightweight energy saving type device for emulsifying liquid

An emulsification device and energy-saving technology, applied in chemical instruments and methods, dissolving, mixers, etc., can solve the problems of increasing production difficulty and increasing production costs, and achieve the effects of light weight, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

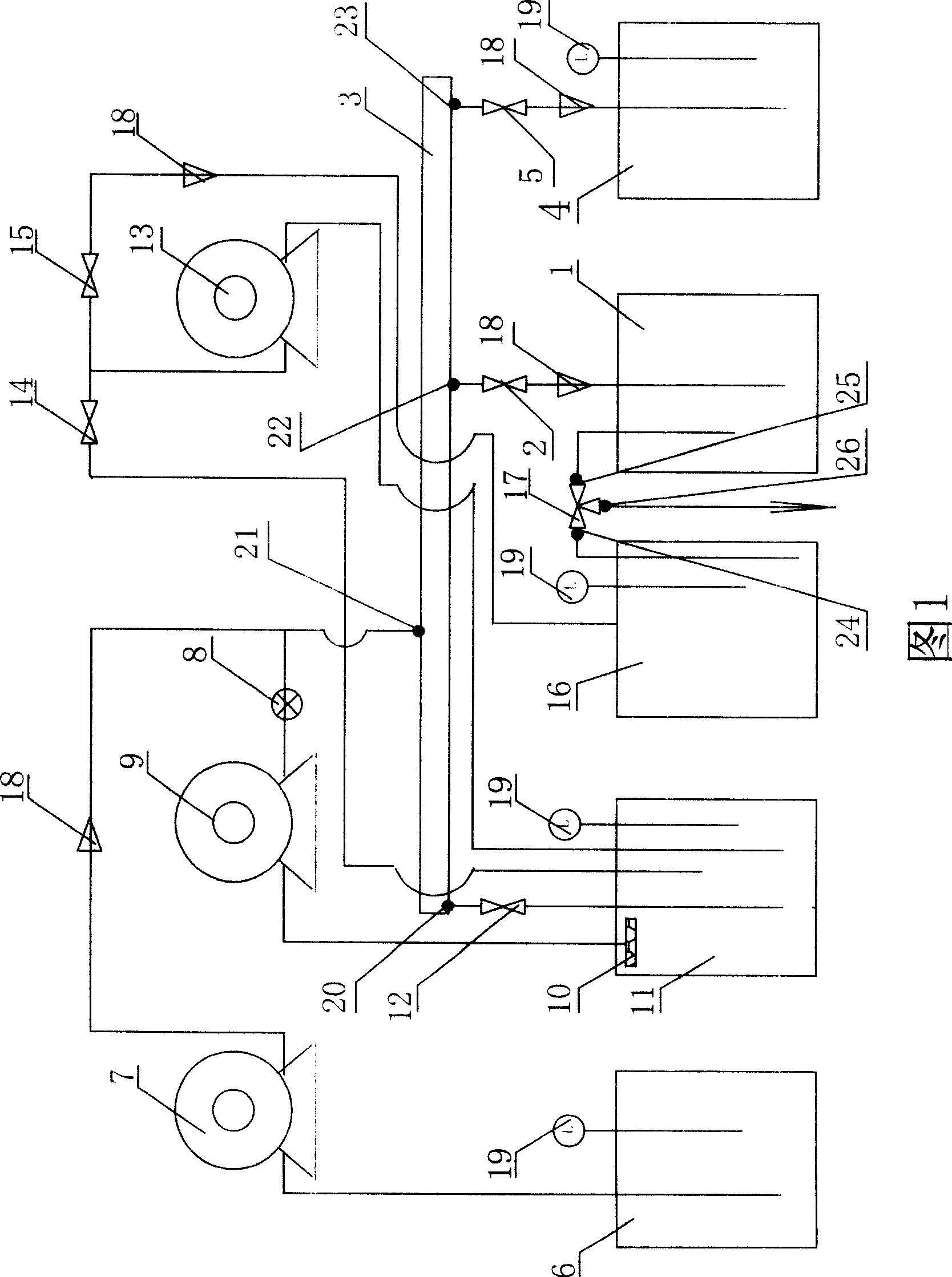

[0020] The dispersion medium box 1 is connected to the filter 18 and then connected to one end of the dispersion medium control valve 2 , and the other end of the dispersion medium control valve 2 is connected to the third nozzle 22 of the confluence chamber 3 .

[0021] The dispersed phase liquid tank 4 is connected to the filter 18 , and then connected to one end of the dispersed phase fluid control valve 5 , and the other end of the dispersed phase fluid control valve 5 is connected to the fourth nozzle 23 of the confluence chamber 3 .

[0022] The additive tank 6 is connected to the inlet of the metering pump 7, and the outlet of the metering pump 7 is connected to the filter 18 and then connected to the second nozzle 21 of the confluence chamber 3, and the second nozzle 21 is connected to another branch pipeline connected to one end of the controller 8 , the other end of the controller 8 is connected to the inlet of the homogenizing pump 9, the outlet of the homogenizing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com