Rotating type water sprayer

A sprinkler and rotary technology, which is applied in spraying devices, spraying devices with movable outlets, etc., can solve the problems of short service life, inability to automatically rotate and spray water according to needs, and affect the appearance of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

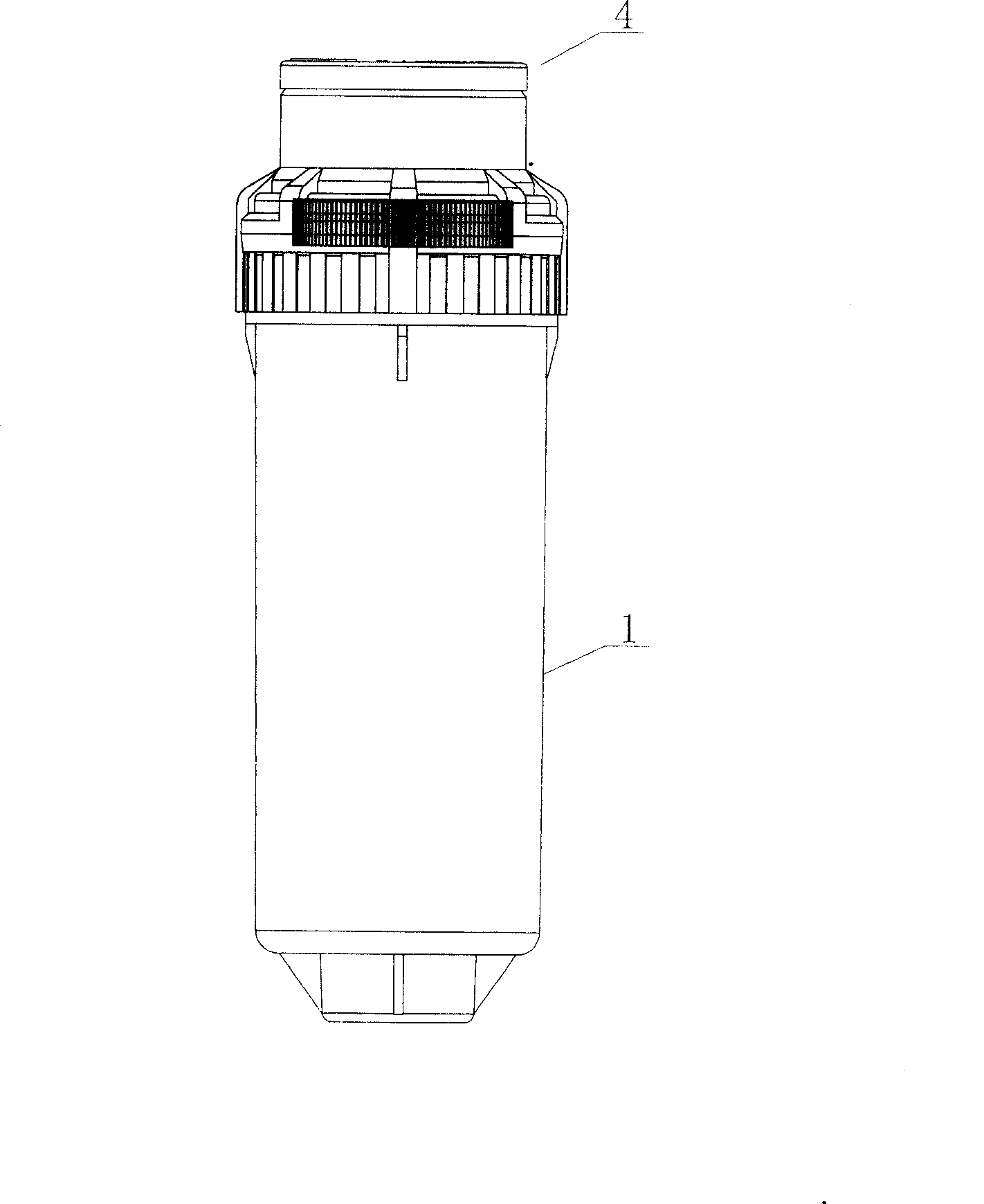

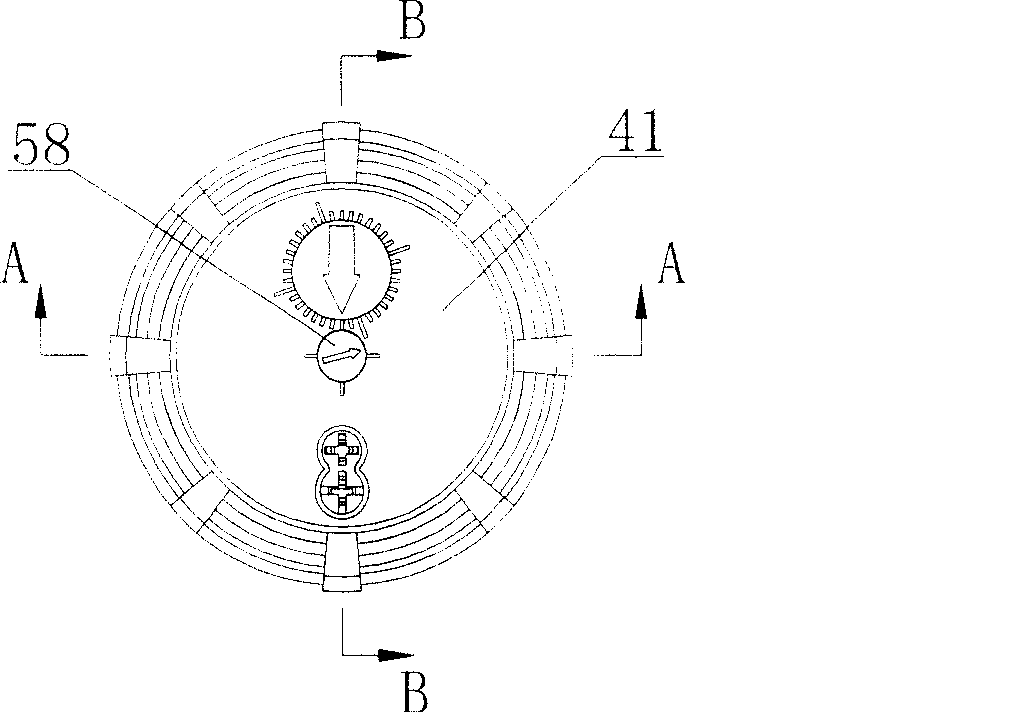

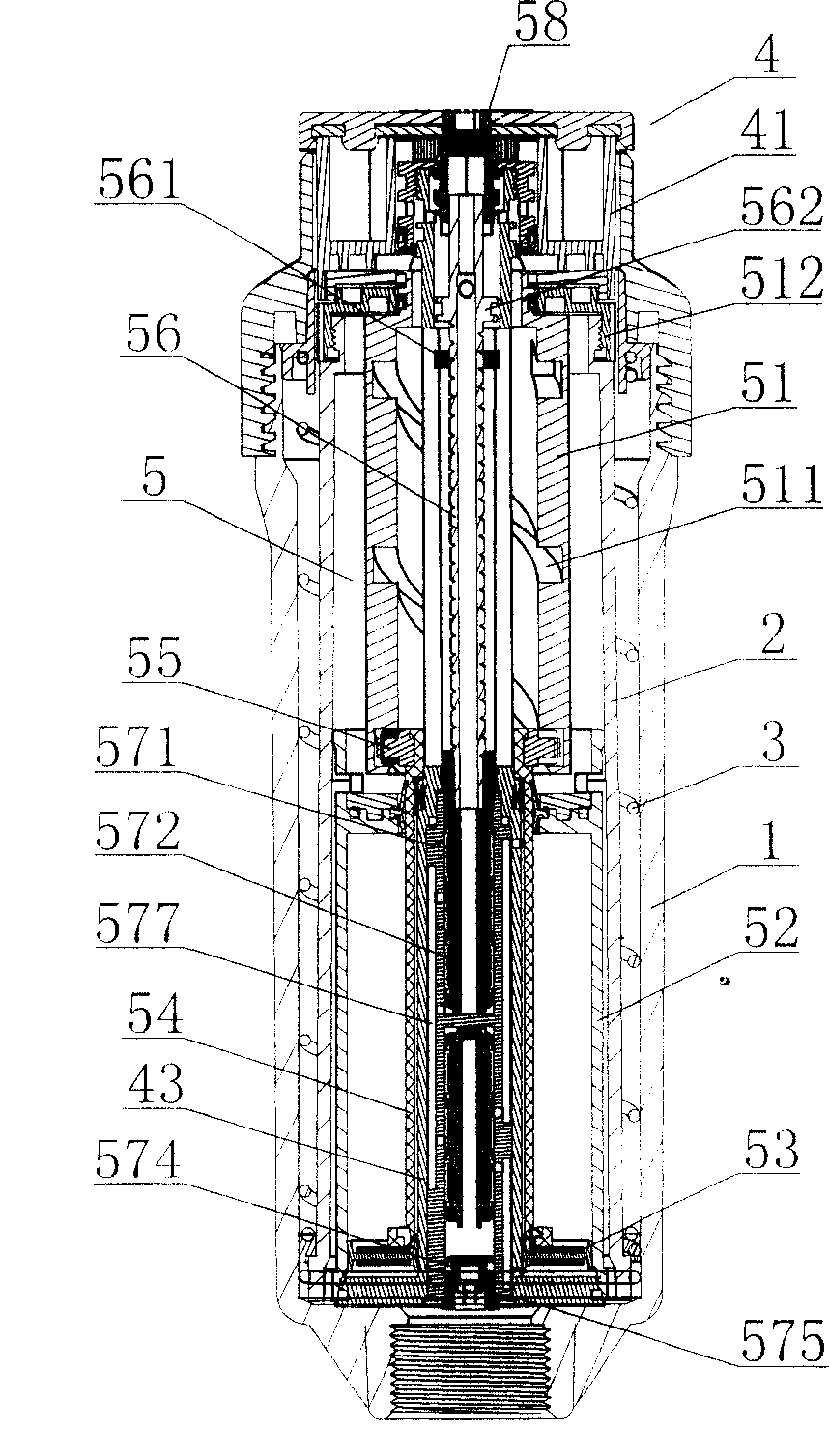

[0021] Such as Figure 1 to Figure 9As shown, the rotary sprinkler of the present invention includes an outer casing 1 with a water inlet at the bottom, a telescopic tube 2 telescopically installed in the outer casing 1, and a return spring that is overlaid on the telescopic tube 2 3. The nozzle assembly 4 and its rotation reversing device 5, the nozzle assembly 4 includes a turntable 41 located at the upper end of the telescopic tube 2, a nozzle 42 embedded in the side of the turntable 41 and inserted into the telescopic tube 2 The water inlet pipe 43, the top of the water inlet pipe 43 is connected to the bottom of the turntable 41 and communicates with the nozzle 42. In order to reduce the processing difficulty of the present invention, simplify the structure of the present invention and prolong its service life, the rotary reversing device 5 includes a jacket The hydraulic cylinder block 52 installed in the telescopic tube 2 at the lower part of the water inlet pipe 43, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com