Mounting grommet for member

A technology for installation and installation holes, which is applied in the direction of connecting components, quick-action fasteners, mechanical equipment, etc. It can solve the problems of difficult replacement of inner hole seats, achieve the effects of reducing assembly man-hours, reducing costs, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

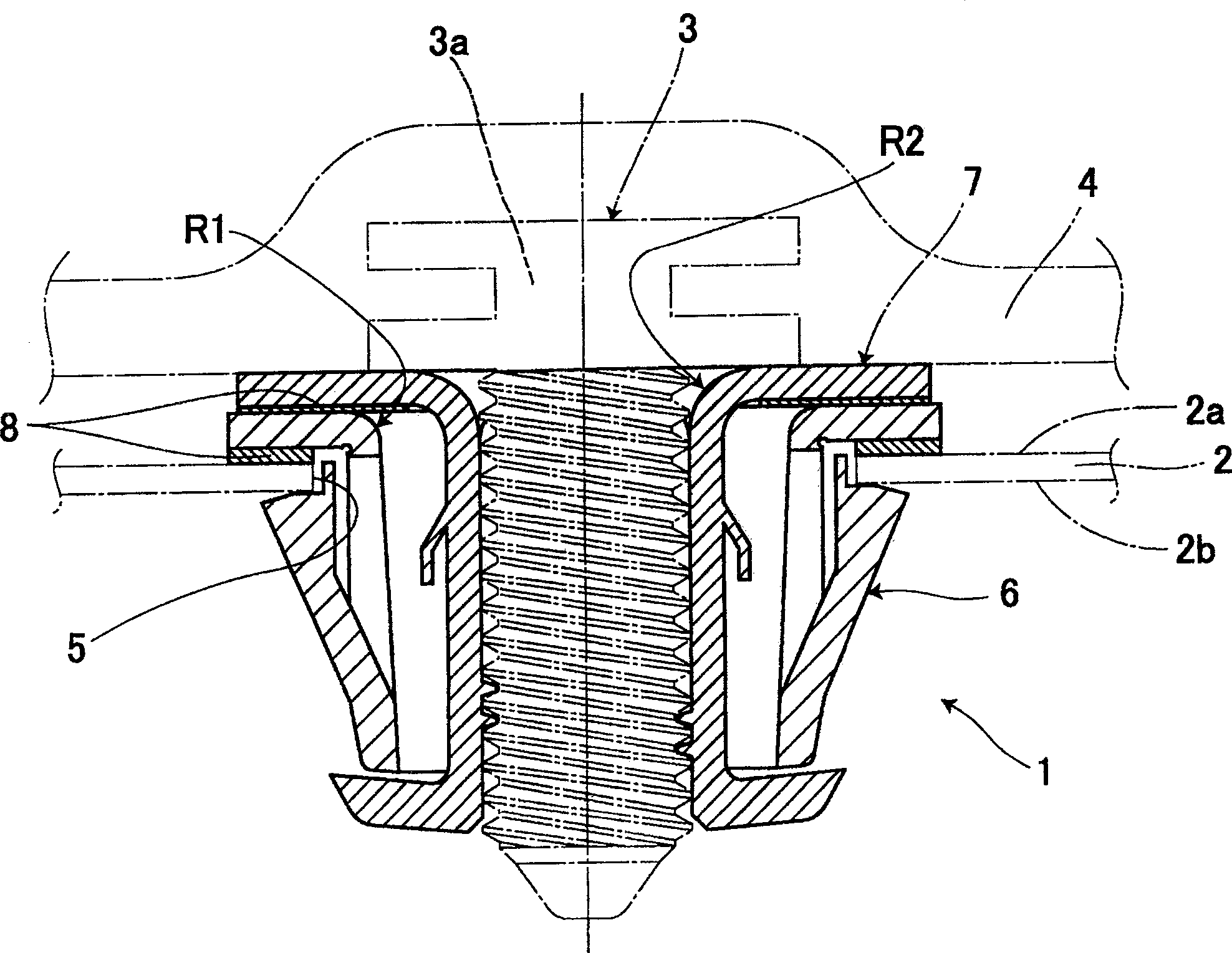

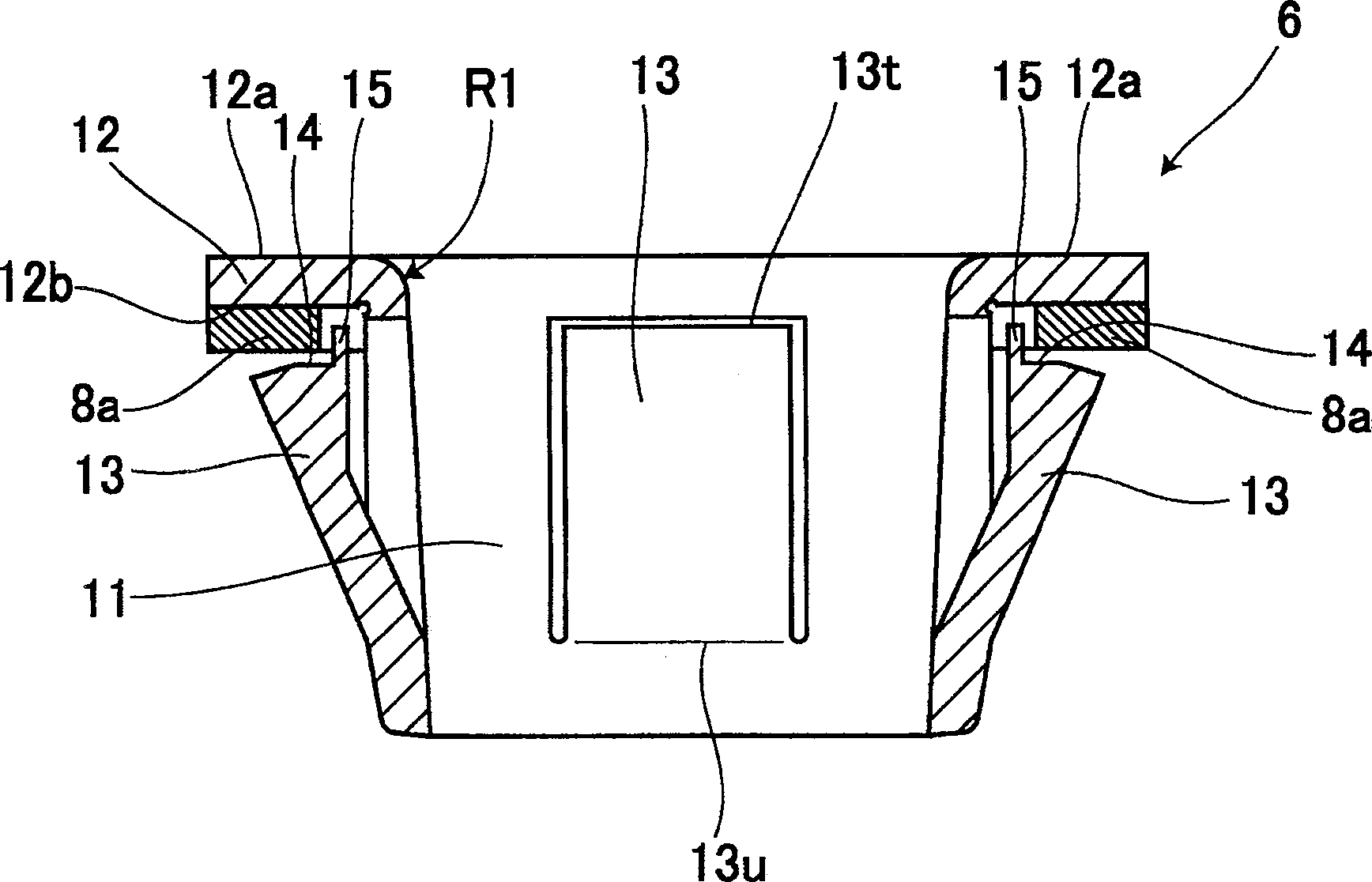

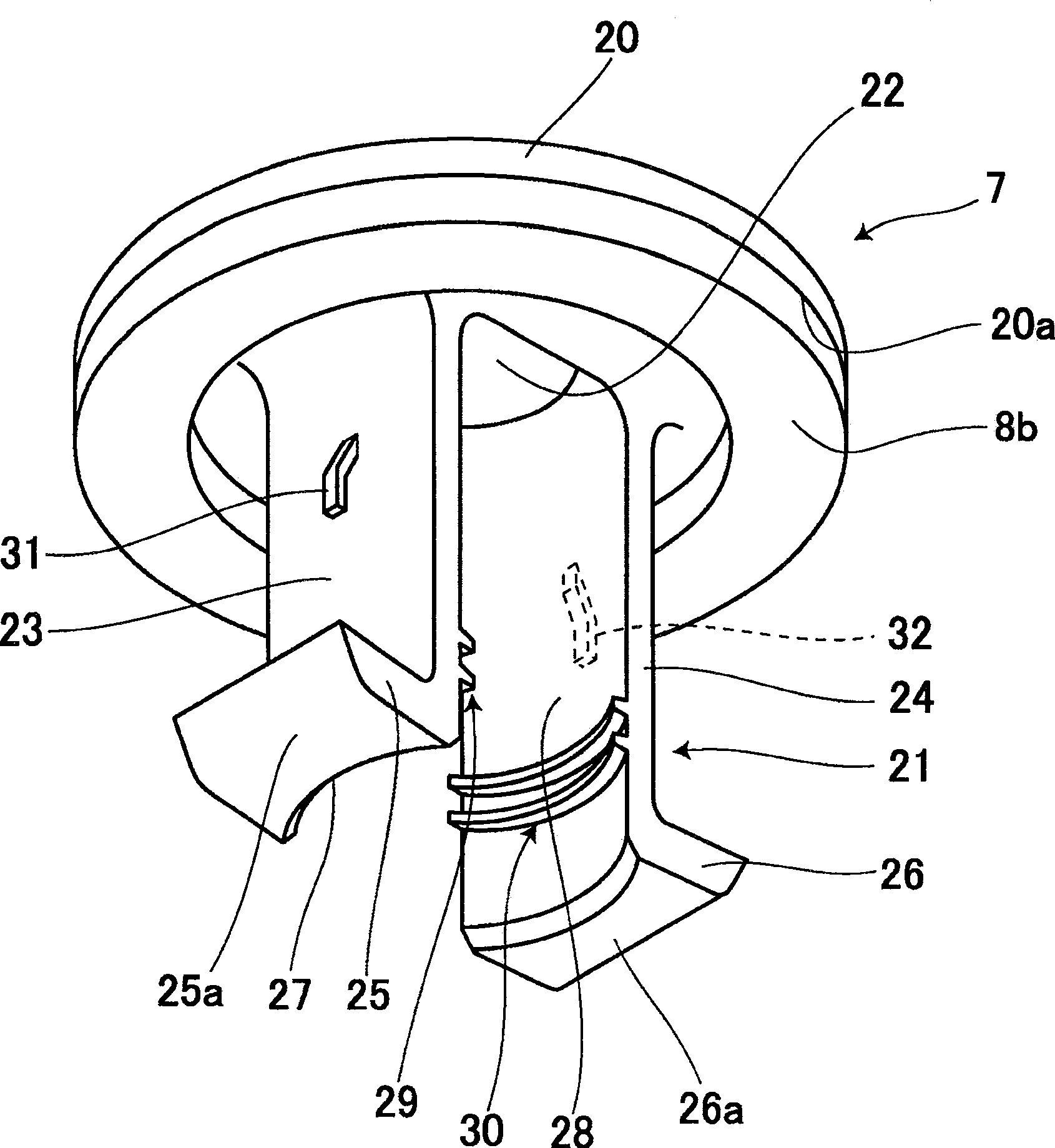

[0076] Refer to the following Figure 9 The second embodiment of the present invention will be described. Figure 9 neutralize figure 1 Corresponding parts are marked with the same reference numerals. and, Figure 9 The illustrated component mounting socket 40 is different from the above-mentioned first embodiment in that the first seal piece 41 , the protrusion 42 and the second seal piece 43 are integrally formed with the outer socket 6 and the inner socket 7 .

[0077] That is, the first stopper portion 12 of the outer hole seat 6 has a first sealing sheet 41 that seals the contact portion between the outer hole seat 6 and the vehicle body 2 to prevent water from entering the vehicle body 2 . The first stopper portion 12 surrounds the mounting hole 5, and the outer peripheral end is inclined to one side 2a of the mounting hole 5 to form a first sealing sheet 41, and has a seal capable of contacting one side of the mounting hole 5 at its front end. Face 41a. The first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com