Double-side organic luminescence display device and its making method

A technology of light-emitting display and manufacturing method, which is applied in the field of double-sided organic light-emitting display device and its manufacturing, and can solve problems such as cost burden and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

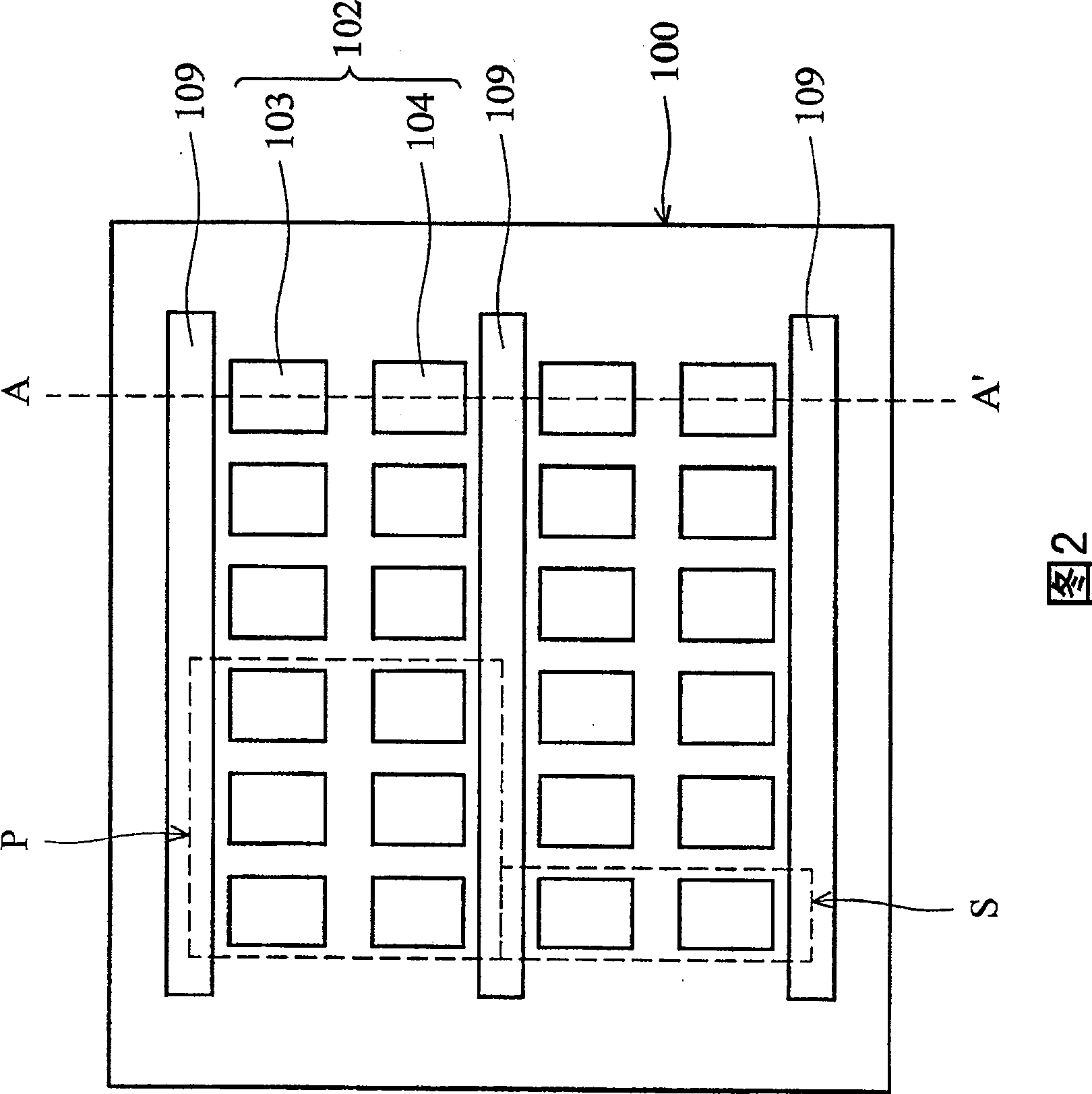

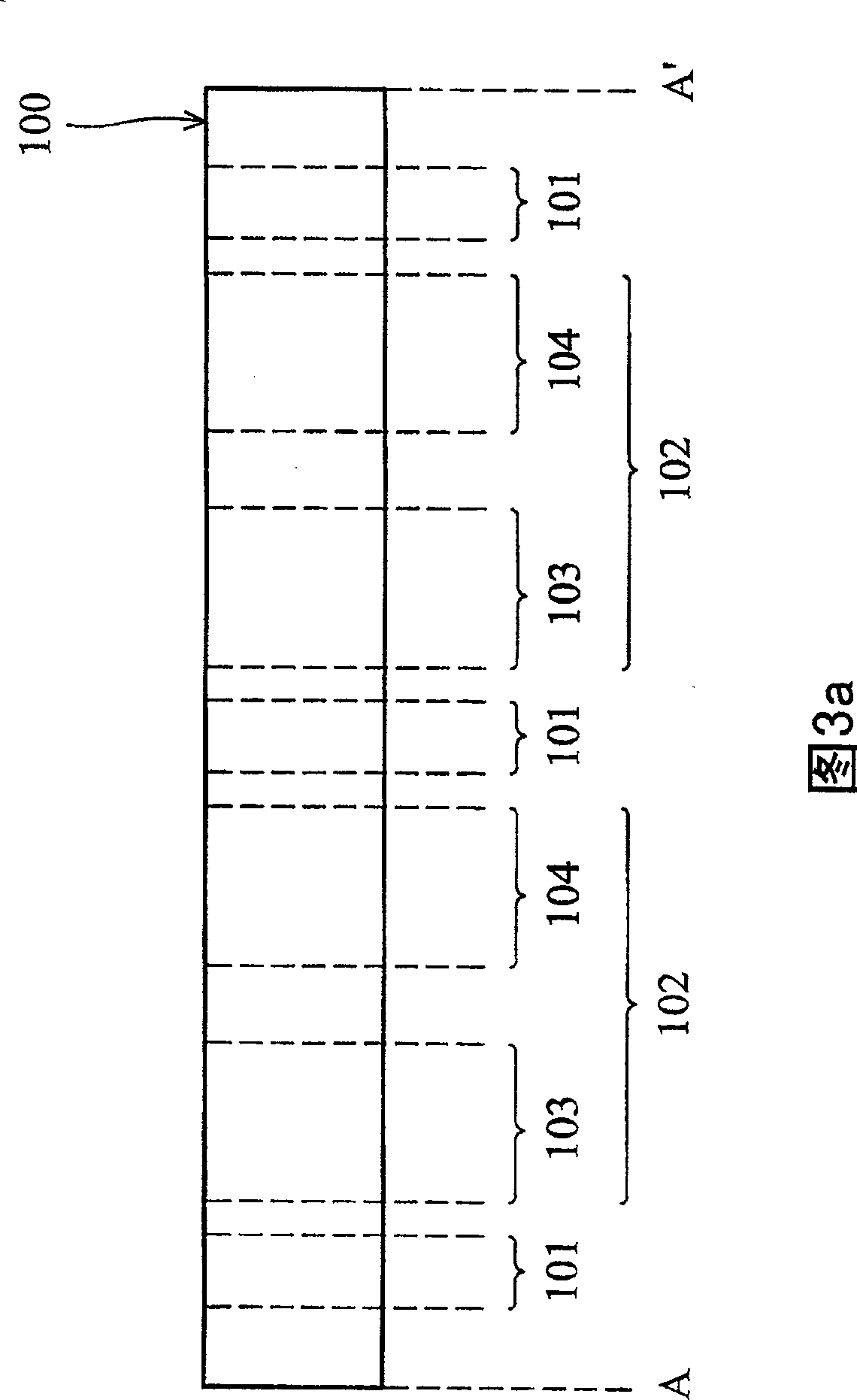

[0070] Please refer to FIG. 2 and FIG. 3a to FIG. 3f. The above figures show the process flow of the double-sided organic light emitting display device according to a preferred embodiment of the present invention. FIG. 2 is a top view, and FIGS. 3 a to 3 f are cross-sectional structural views corresponding to the cut line A-A' of FIG. 2 .

[0071] First, referring to FIG. 2 and FIG. 3 a , a substrate 100 is provided, the substrate 100 has a plurality of non-display regions 101 and display regions 102 , and two adjacent display regions 102 are separated by the non-display region 101 . Wherein, the display area 102 further includes an upward-emitting display area 103 and a downward-emitting display area 104 . In this embodiment, three adjacent upward-emitting display areas 103 (which can each emit light in the three primary colors of RGB) and three adjacent downward-emitting display areas 104 (which can each emit light in the three primary colors of RGB) form a pixel P , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com