Rapid alcoholization machine for foodstuff

A food and fast technology, applied in the chemical/physical/physicochemical process of applying energy, the preparation of alcoholic beverages, etc., can solve the problems of long storage time of food and organic substances, damage to the natural character of organic substances, long production cycle, etc. , to achieve the effect of saving alcoholization time, not easy to deteriorate, and accelerating capital turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

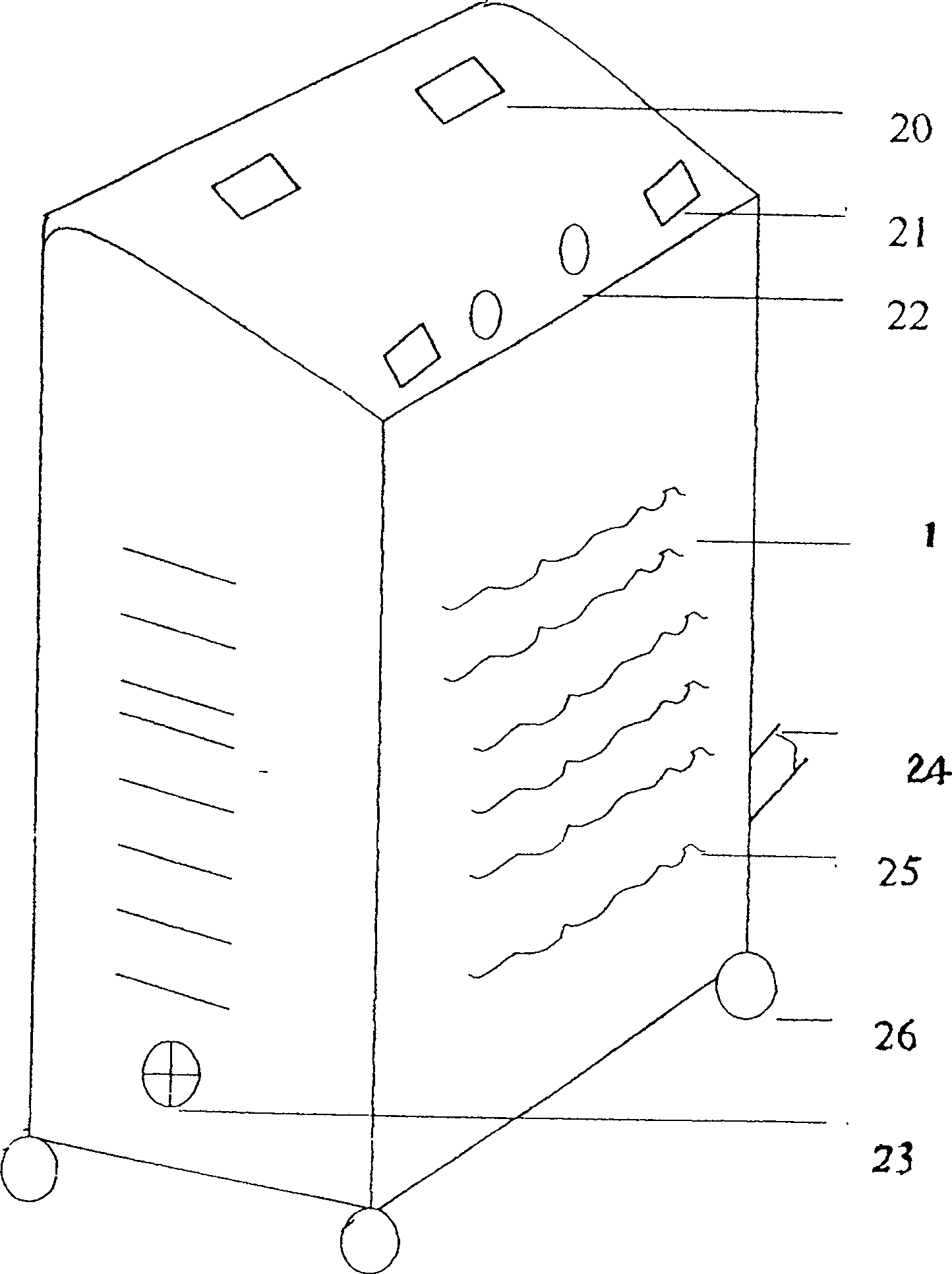

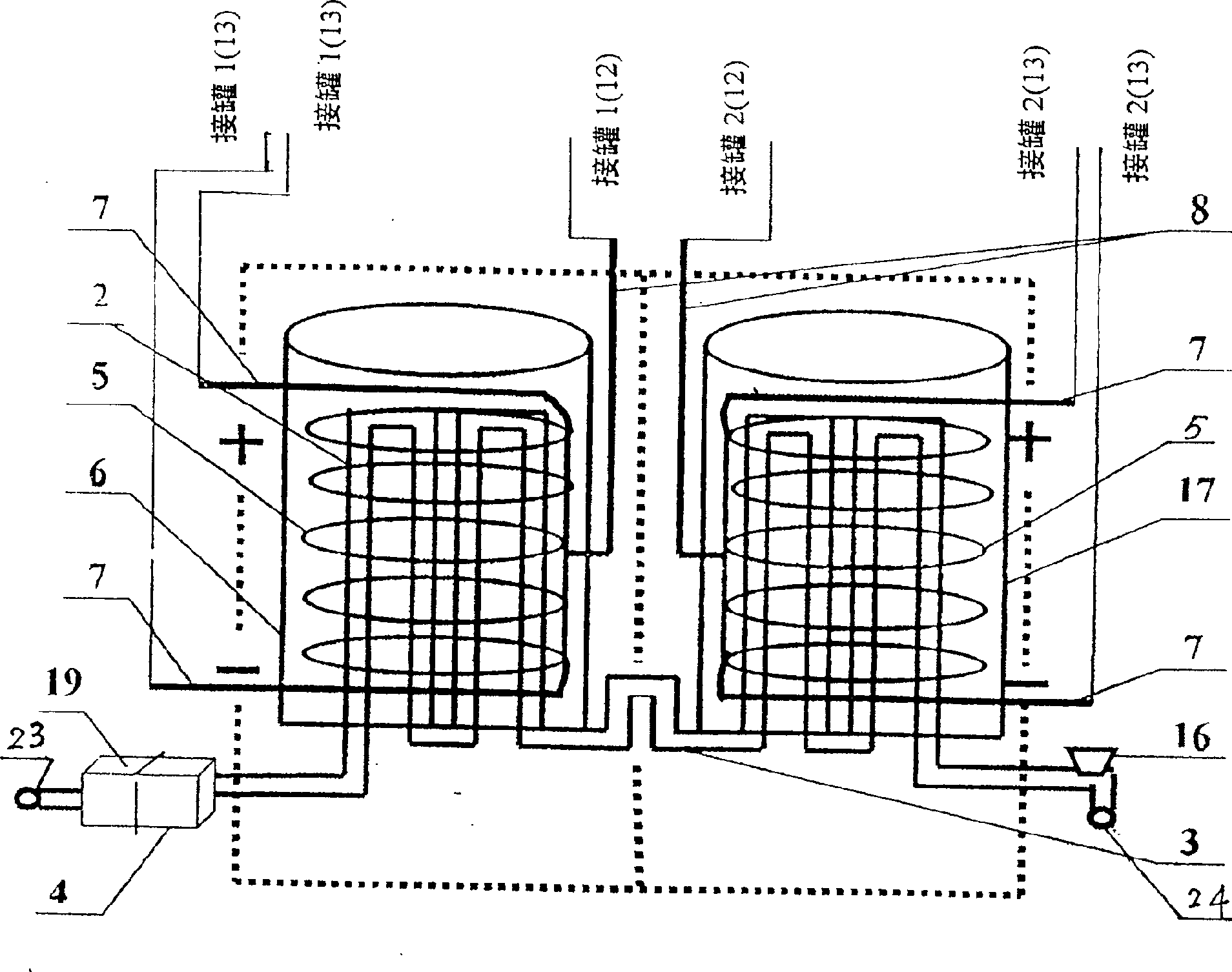

[0021] figure 1 , figure 2 , image 3 It is a schematic diagram of the special liquid alcohol solidification machine using two magnetization tanks. The casing 1 is surrounded by a window 25, and the two are equipped with a liquid inlet 23 and a liquid outlet 24; the top of the casing 1 is equipped with a magnetic wave switch 21, a magnetic wave Table 20, indicator light 22; Two magnetized tanks 1 (6) and 2 (17) connected in series by the excessive conveying uniform pipeline 3 are arranged in the casing 1. The magnetization tank 1 (6) and the magnetization tank 2 (17) are respectively connected with a high-voltage electrode 7, an electromagnetic coil 5 and a low-voltage electrode 8. A flow valve 4 and an alcohol sensor 19 are installed between the liquid inlet 23 and the liquid delivery magnetization pipeline 2 ; an outlet joint 16 is provided at the liquid outlet 24 . Four machine wheels 26 are equipped with at the bottom of casing 1 . One or more magnetization tanks can ...

Embodiment 2

[0023] Figure 4 , Figure 5 , Image 6 It is a schematic diagram of simultaneous alcoholization of liquid and solid, using three magnetized tanks.

[0024] Under liquid working conditions, food inlet 31, food outlet 33 and stepper motor 29 are added, stepper motor shaft 30 drives belt 27 to rotate, conveyor belt 28 sends solid food into magnetization channel 34 and alcoholizes solidification together.

[0025] It is also possible to cancel the liquid working state, and only adopt the solid state to solidify food and other related substances.

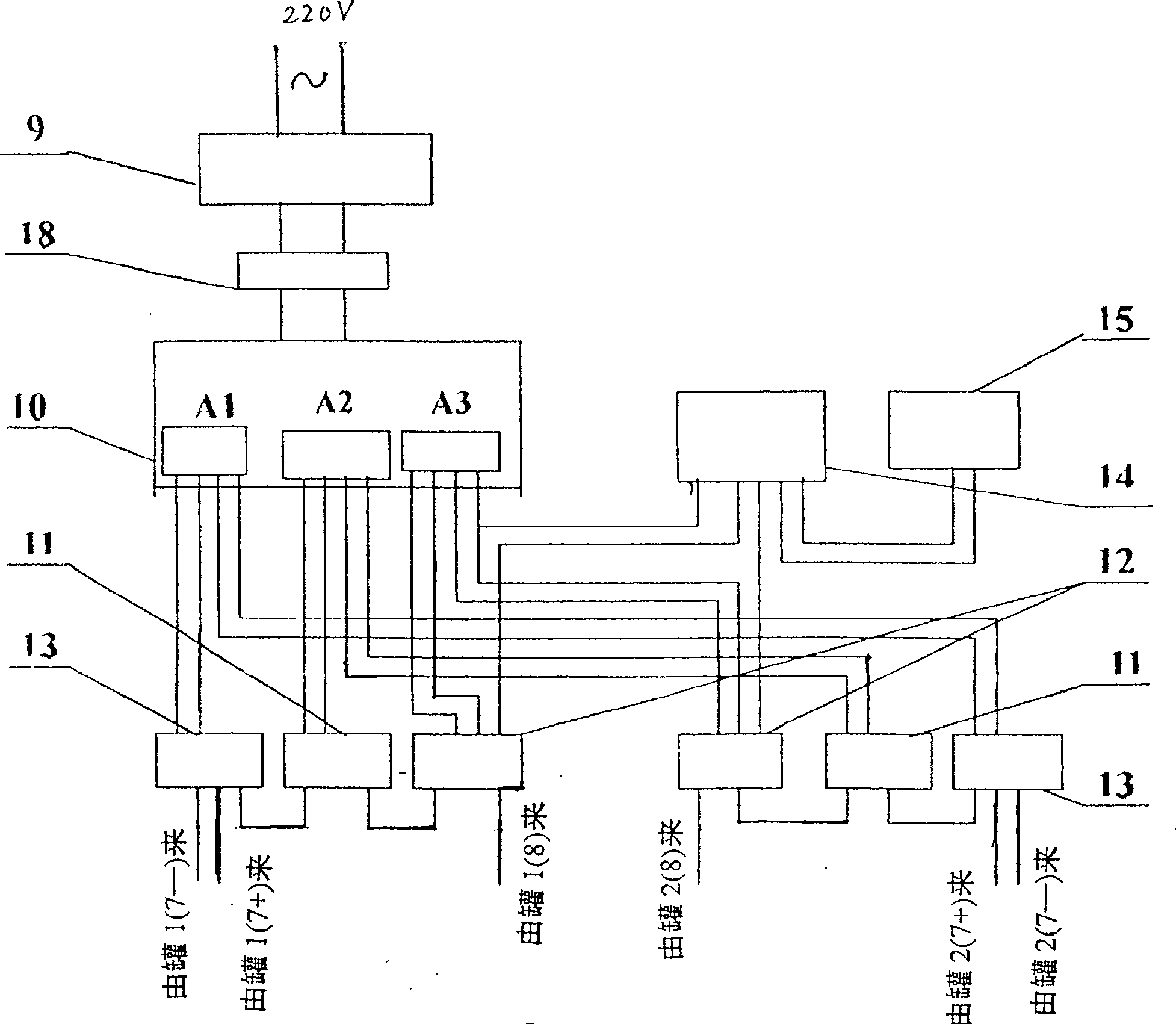

[0026] When working, turn on the power magnetic wave switch 21, and the AC 220V enters the power automatic protection switch 18 through the power filter 9 to the input terminal of the transformer 10, and the transformer 10 outputs multi-channel three groups of power sources: one group provides a low-voltage 400V DC power supply 11 for high-frequency transmission The module 13 is used; one group provides a high-voltage 800V DC power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com