Restraining gasket for assembling filler box and method for assembling restrained mechanical joint

A technology of stuffing box and gasket, which is applied in the connection of stuffing seal with fluid pressure, mechanical equipment, non-detachable pipe connection, etc., which can solve the benefits of not having stability and increase the factors of buried or trenched installation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a detailed description of the present invention. Those skilled in the art will appreciate that the features presented herein are intended for purposes of illustration against the inventor's most preferred embodiment and should not be construed as limiting the scope of the invention. References herein to "pipe" will equally be understood to refer to any length of pipe, attachment, fitting or any other connecting device or element, regardless of method or material of manufacture.

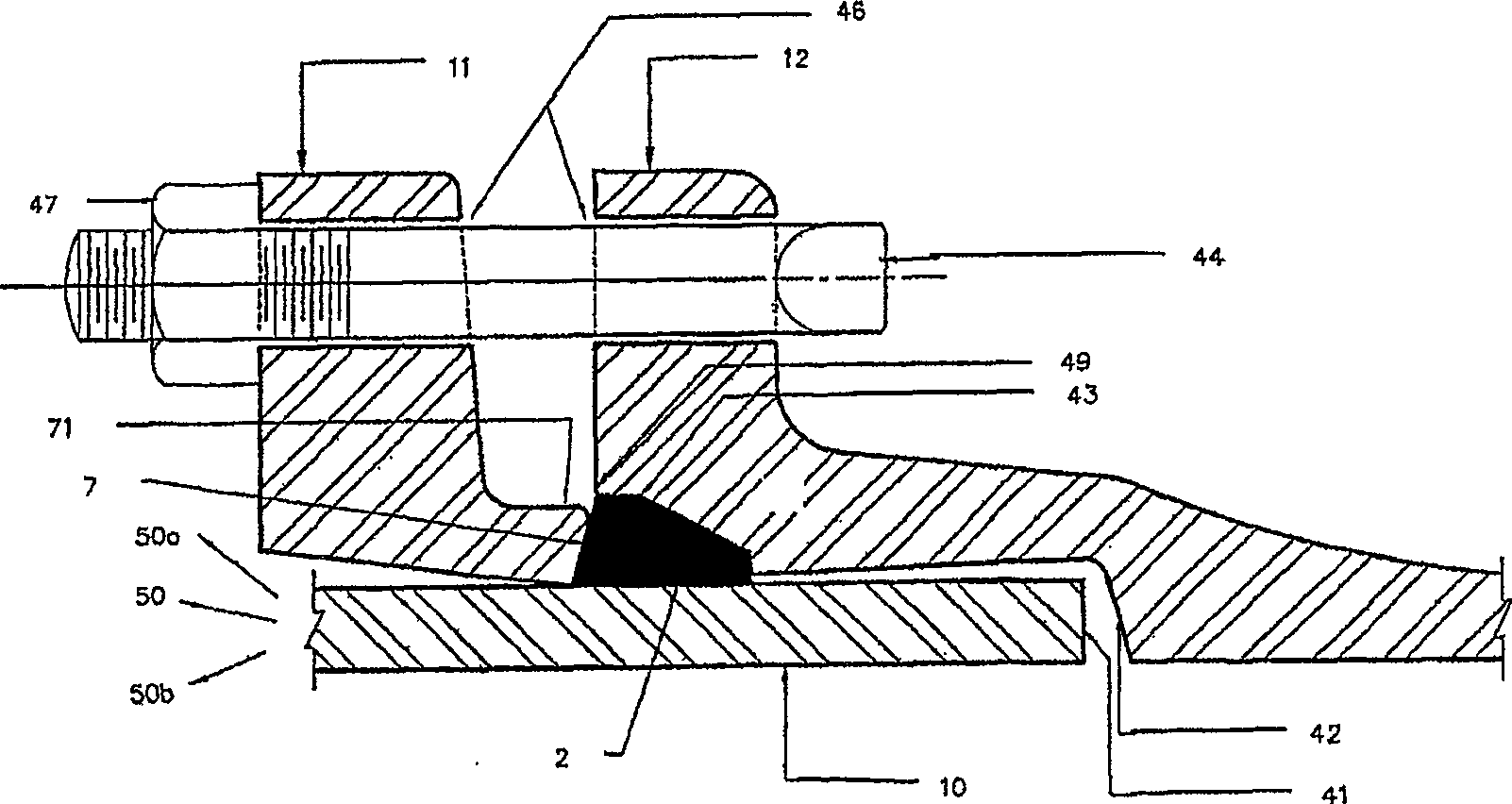

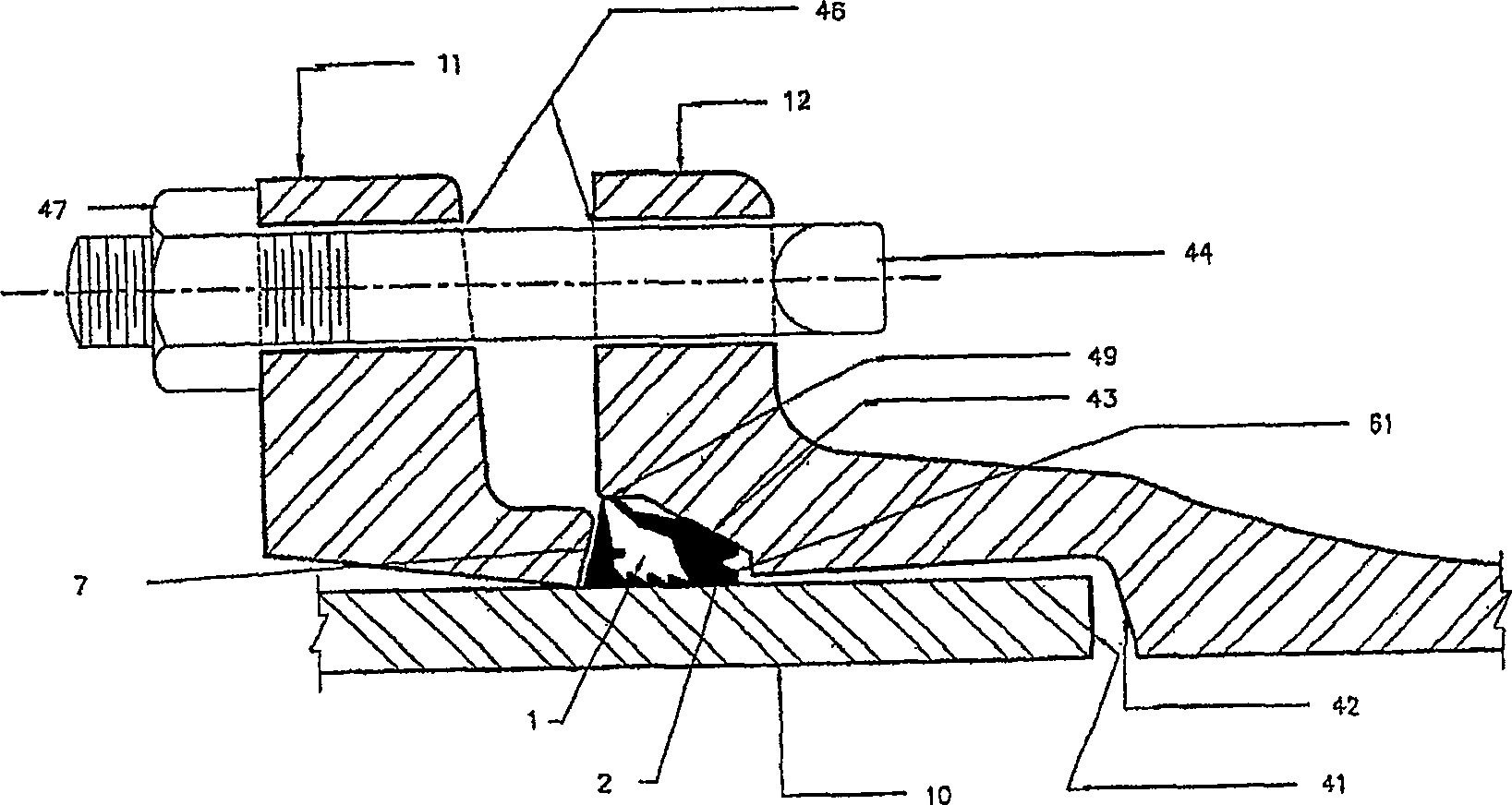

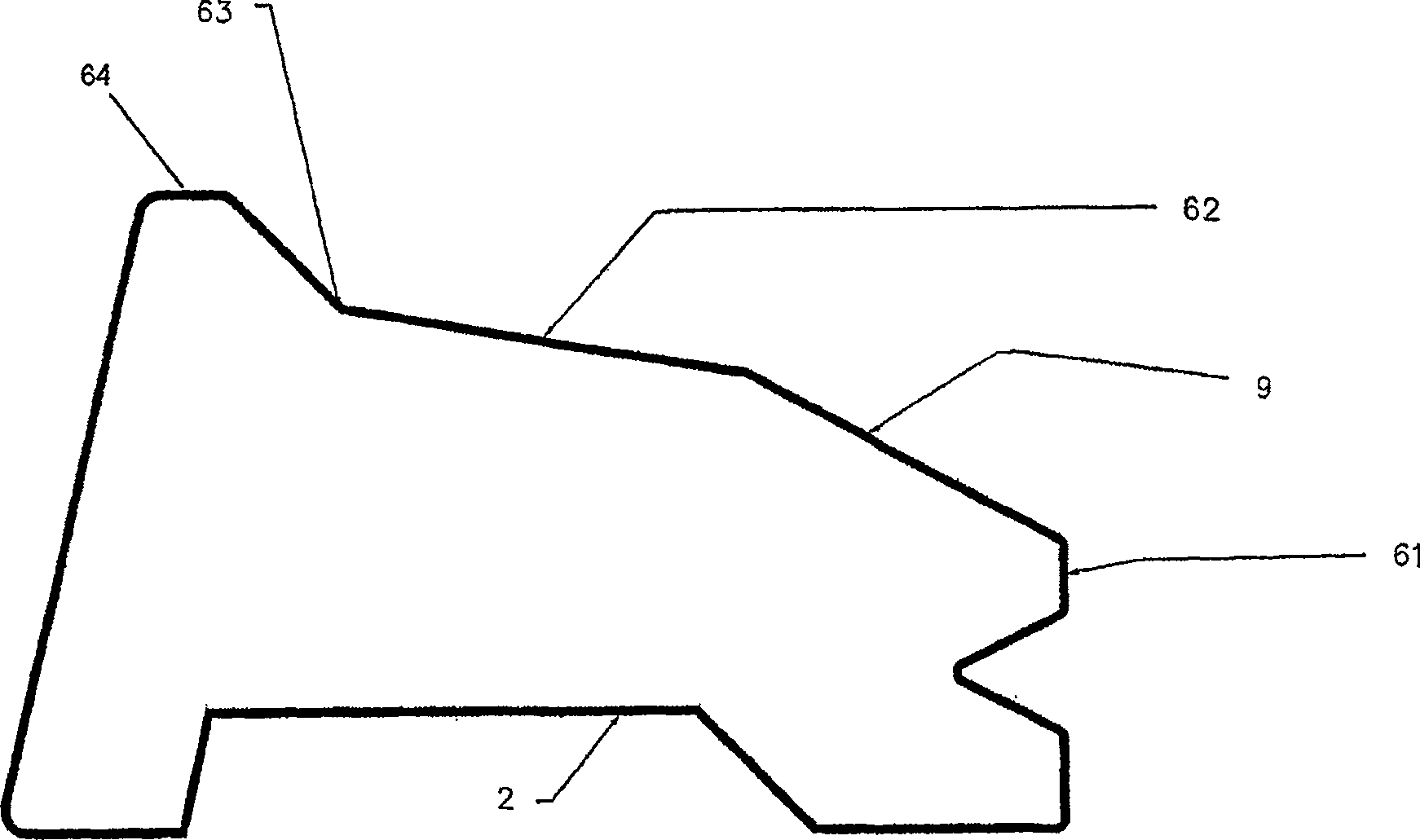

[0029] now go to figure 1 , figure 1 Diagram representing a typical mechanical joint. Assembly of the joint according to the invention is carried out according to techniques known in the art. Specifically, but not limiting to known modifications that will be equally applicable to the present invention as if they were known techniques, the linker contains the following elements satisfying the following relationships. A compression ring or gland 11 is placed on the pipe plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com