Process for producing mica pulp by mica paper waste material

A technology of mica paper and mica, applied in pulp beating/refining method, pulping with inorganic alkali, recycling technology, etc., to achieve the effects of strong practicability, improving economic benefits, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

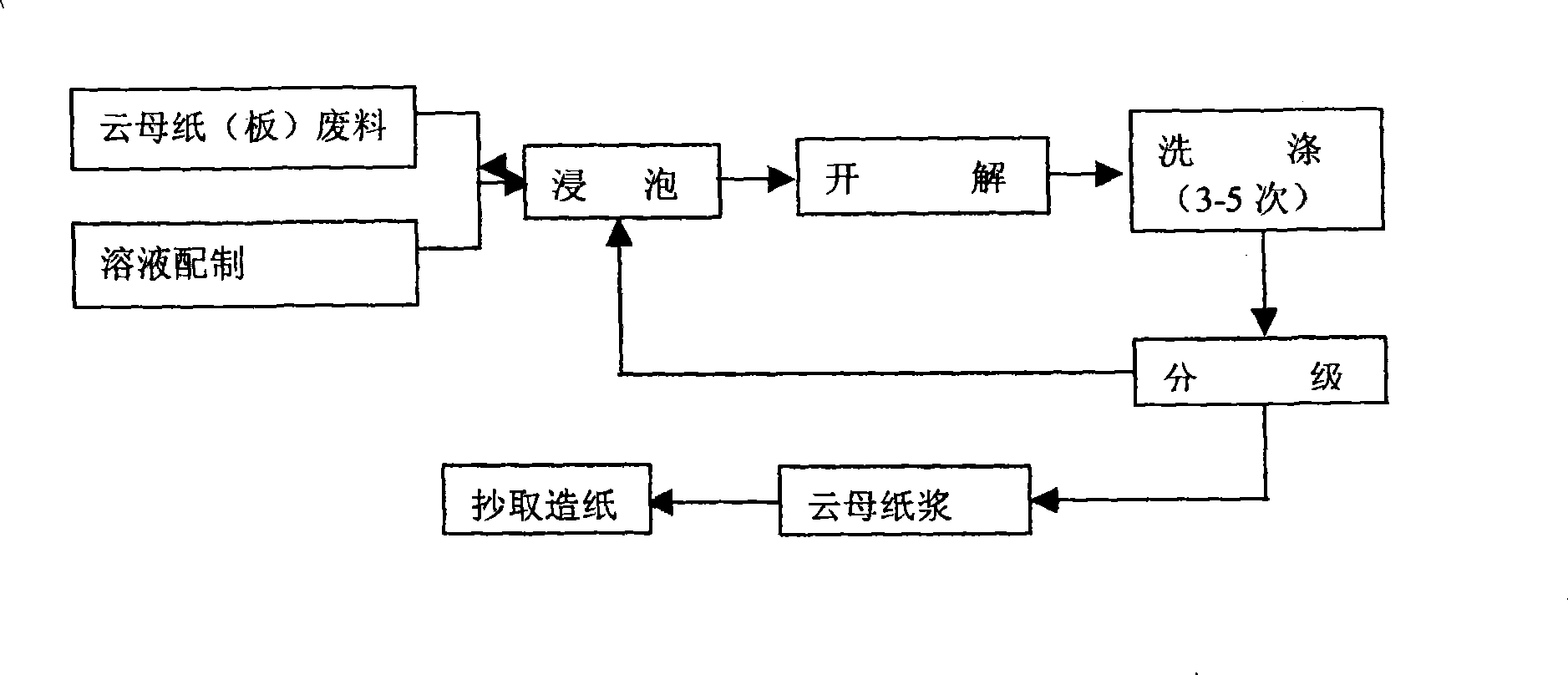

[0013] The invention provides a method for producing mica pulp by using mica paper waste, which adopts chemical soaking to react chemically with adhesive glue to separate the adhesive glue from mica. Then use mechanical unpacking and cleaning, pulp the mica paper waste, and re-take the mica paper.

[0014] Process flow of the present invention is as shown in the figure, and concrete production comprises the following steps:

[0015] (1) Place mica paper waste in industrial caustic soda (NaOH) solution, soak at room temperature for 62-82 hours,

[0016] (2) Stir with a high-speed beater for 1 to 2 hours to decompose the soaked mica paper waste,

[0017] (3) Wash repeatedly 3 to 5 times until the pH of the washing liquid is 8 to 9,

[0018] (4) Classify the washed mica pulp, and the mica paper waste that has not been decomposed or not fully decomposed flows into the next cycle to continue soaking and decomposing, and the decomposed pulp is sent to the mica paper machine for pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com