Injection molding nozzle

A nozzle and nozzle body technology, applied in the field of die-casting nozzles, can solve the problems of damage, unsealing, and the centering sleeve cannot be kept close to the cavity of the mold, so as to reduce the risk of cold blockage and achieve the effect of good thermal separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

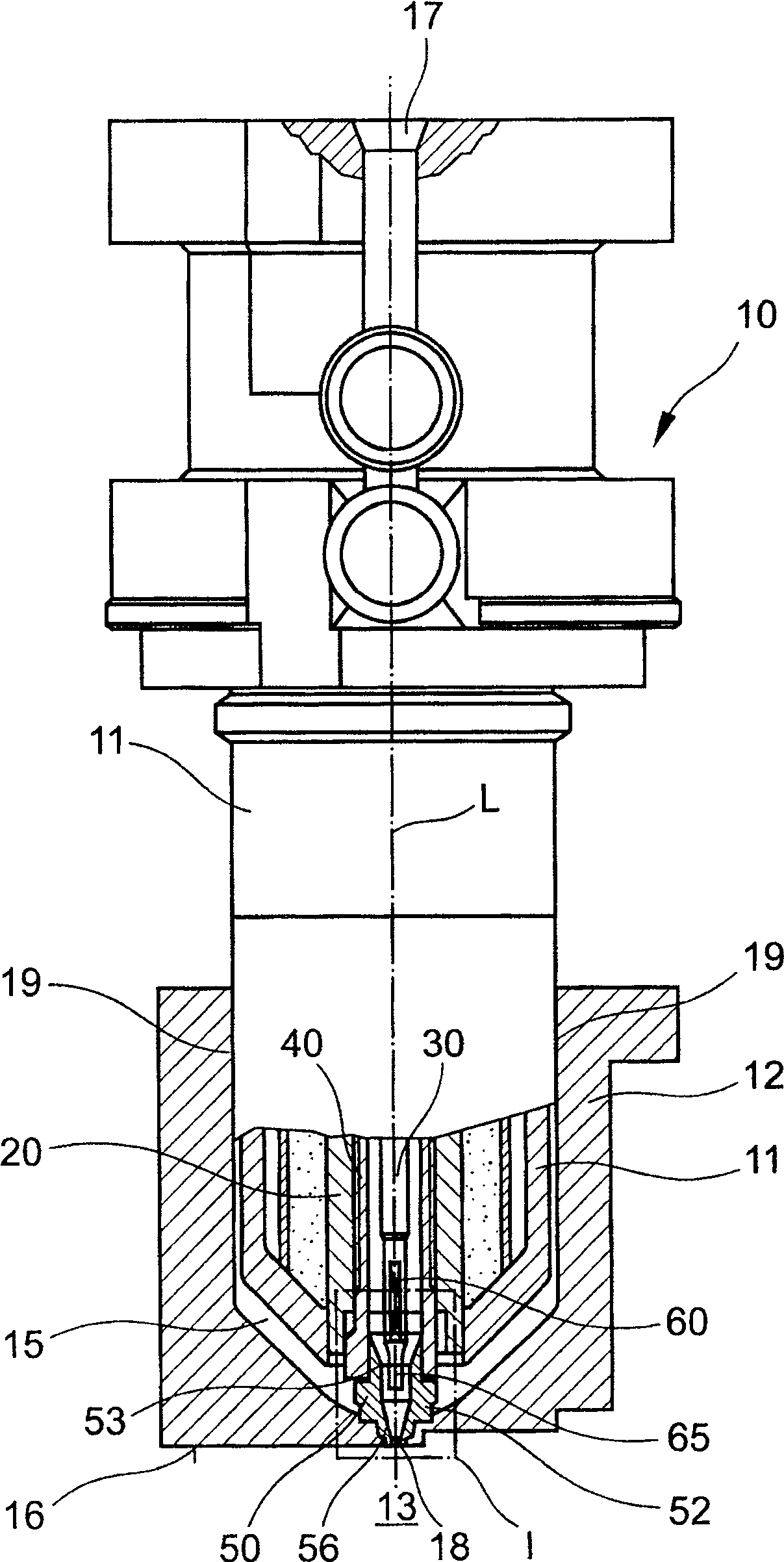

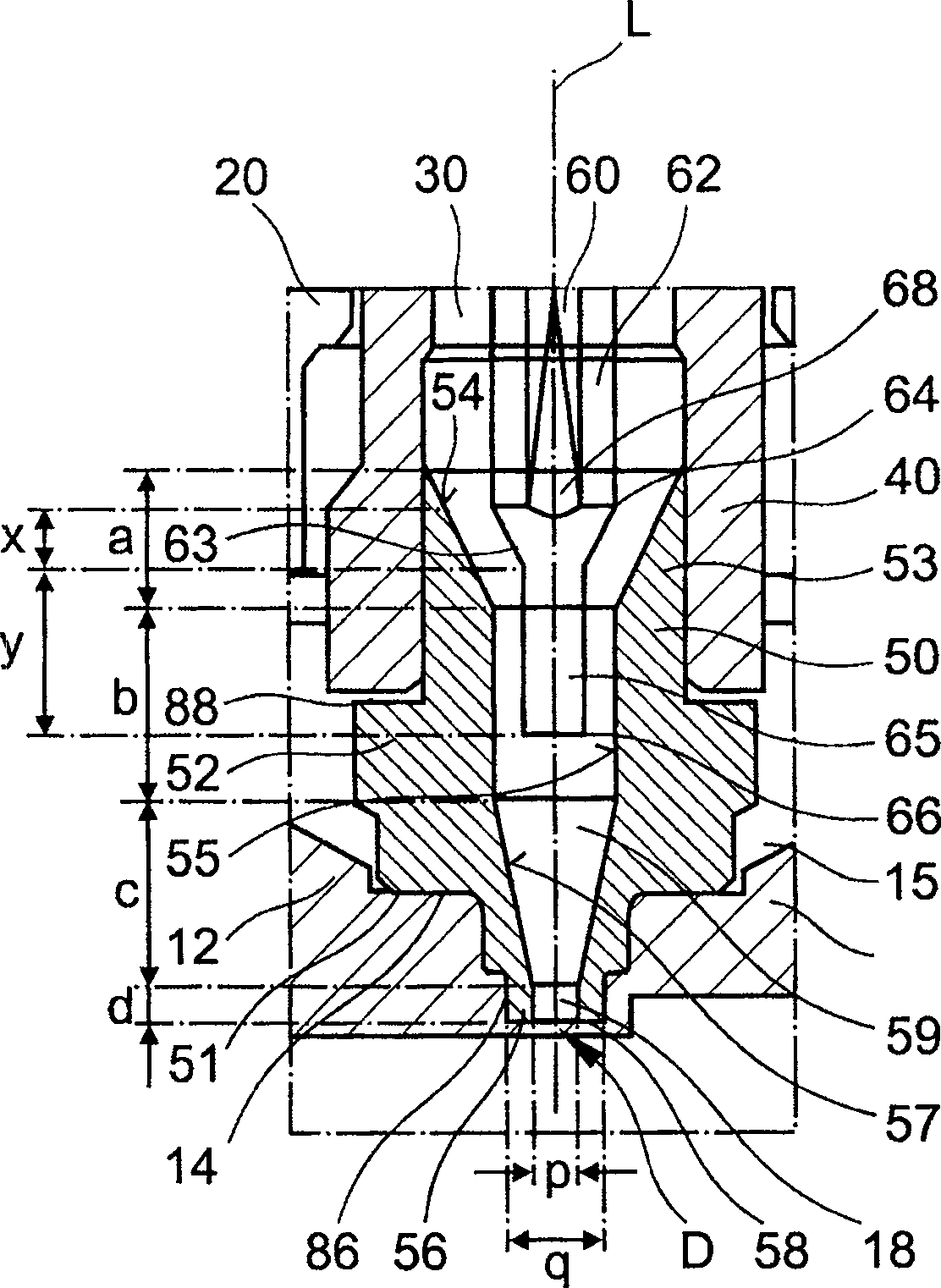

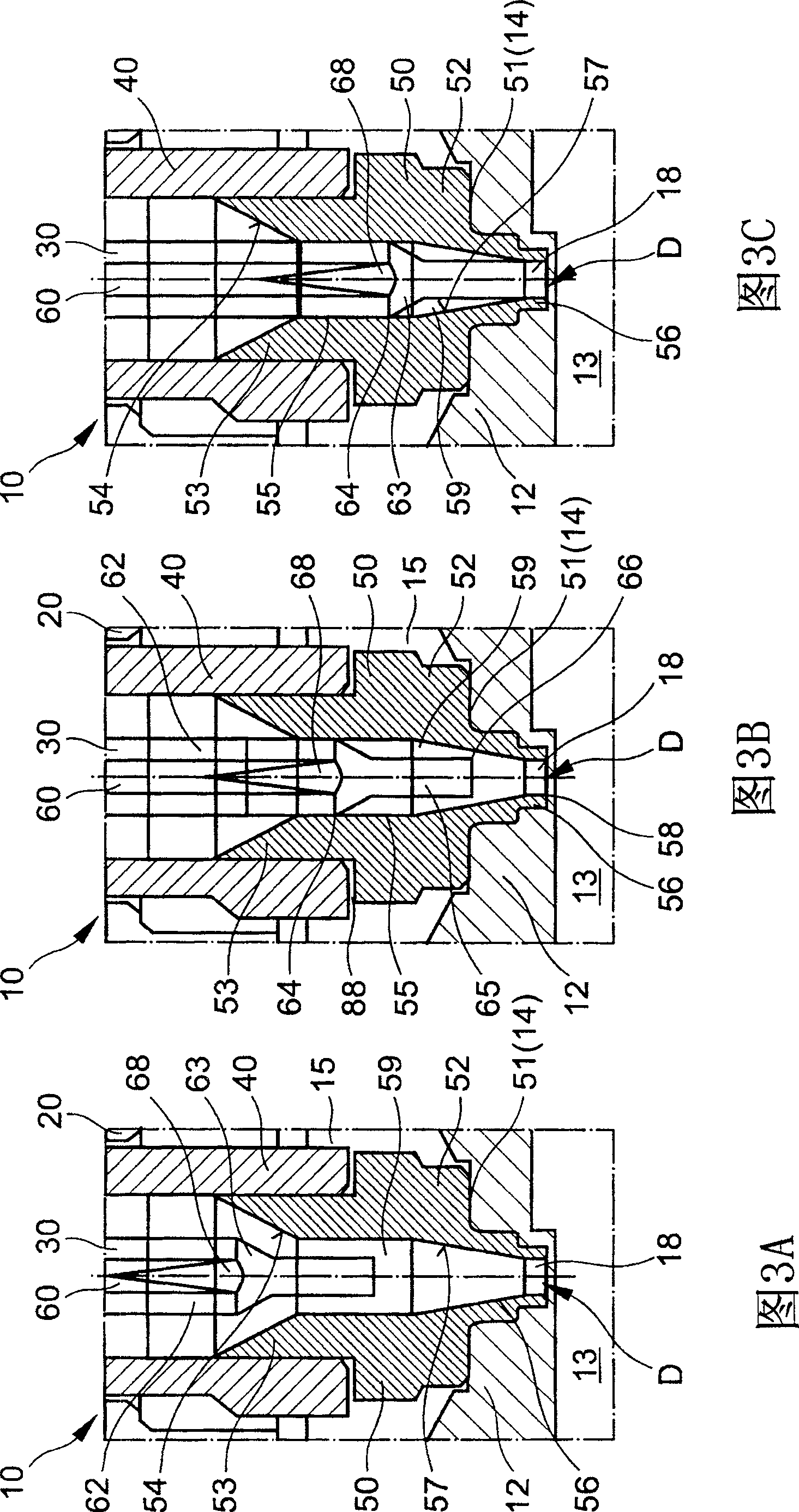

[0030] figure 1 The die-casting nozzle designated 10 as a whole is designed as a needle-shaped shut-off nozzle and is a component of the die-casting tool (not shown). It has a preferably externally heated nozzle body 20 in the housing 11 , which forms a flow channel 30 concentrically to the longitudinal axis L on the inside. The melt to be processed, for example a metal, silicon or plastic melt, is conveyed from the material delivery opening 17 to the mold cavity (not shown in detail) via the flow channel 30 . The latter is formed between form parts 12 , 13 fastened to a formwork (not shown).

[0031] A spray head 40 made of a highly thermally conductive material is preferably screwed into the nozzle body 20 , which continues the melt channel 30 downwards. The spray head 40 , the nozzle body 20 , the housing 11 and the form part 12 delimit an air gap 15 which thermally separates the needle-shaped closing nozzle 10 and the form part 12 from each other. The housing 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com