Method for changing printing plates on cylinders

A technology of cylinder and printing plate, which is applied in the field of changing the printing plate on the cylinder, which can solve the problems that the replacement time of the printing plate is not enough, shorten the replacement time, save time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

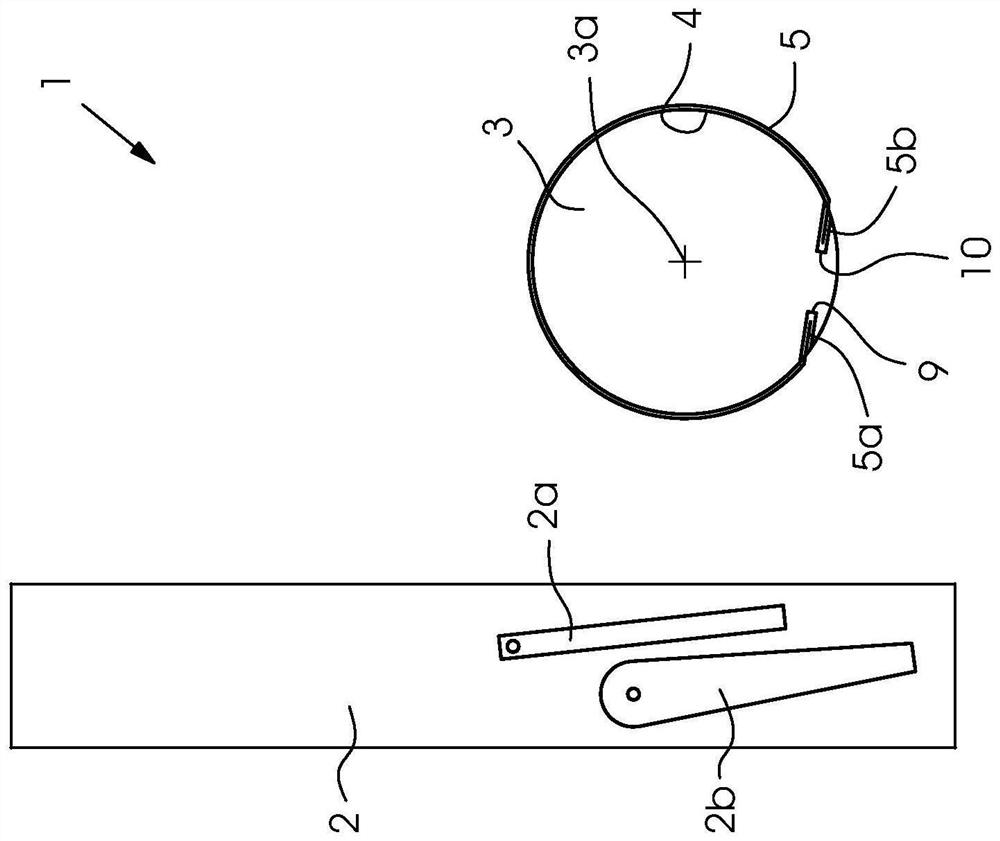

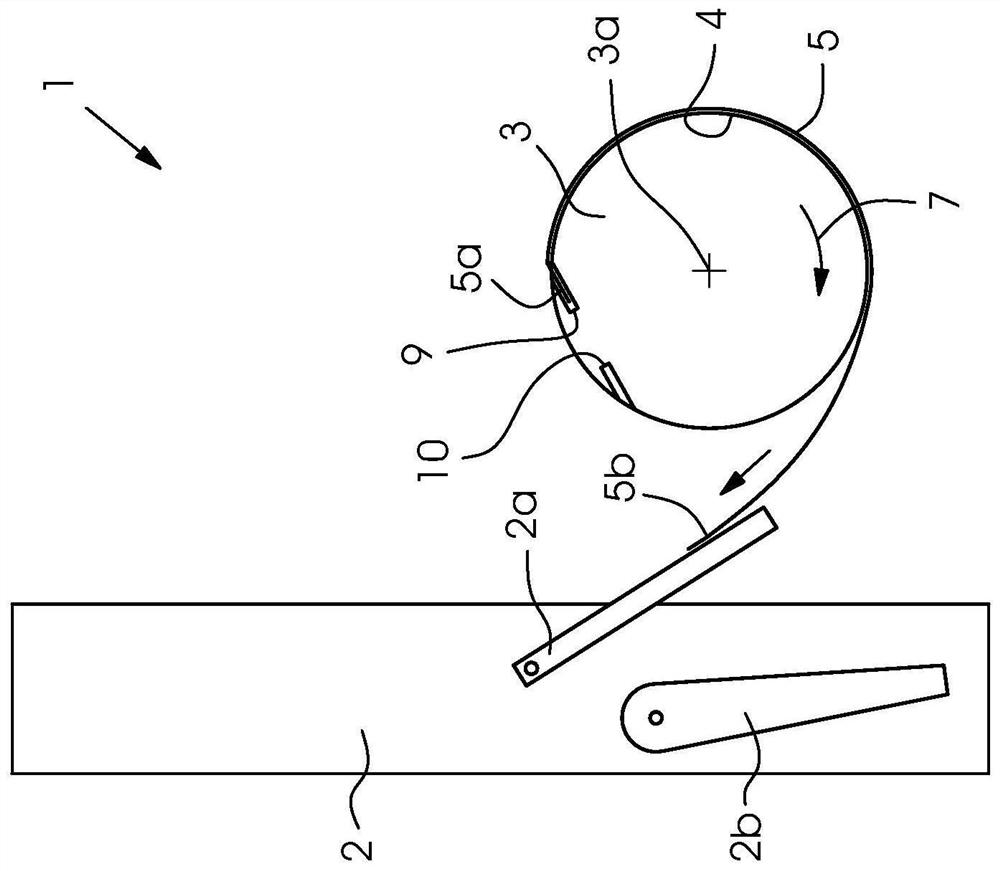

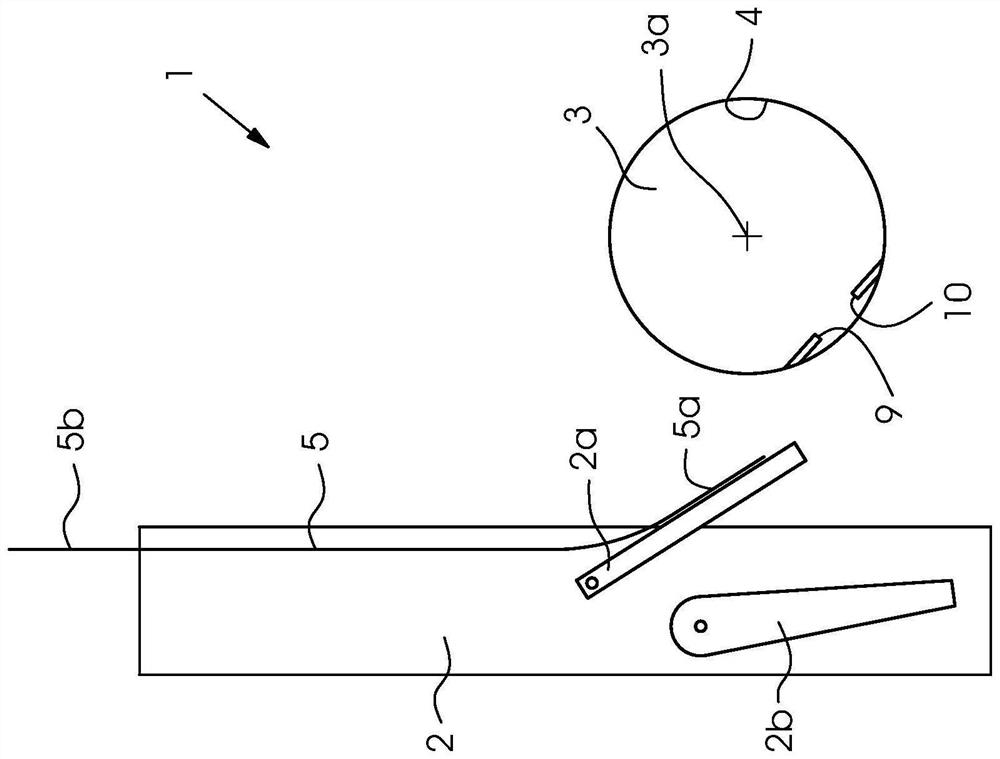

[0032]Figure 1 to 7 The preferred embodiment of the present invention in accordance with the preferred embodiment of the present invention is illustrated in a schematic side view.

[0033]infigure 1 The printing press of the printing machine 1, in particular processing page is shown, which has an automated plate transform device 2 and a roller 3, in particular imprinting plate (or plate drum). The plate transform device has a swingable first guide 2a and a swingable second guide 2b for the plate to be converted, and a roller having not shown. The drum 3 and the plate transform device 2 are supported (or fixed) in a side wall not shown in the printing press 1. In order to perform an automated plate transformation, a control device that is also not shown is provided. The control device controls the rotational motion of the drum, the swing moving movement of the guide, and the translation of the plate to be shifted, and the translational movement of the plate to be transformed.

[0034]The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com