A circular curved surface flow calibration tool

A flow and curved surface technology, which is applied in the field of circular surface flow calibration tooling, can solve the problems of difficult to achieve simultaneous calibration of porous positions, low calibration efficiency, poor sealing, etc., to reduce the time for tooling changeover, solve the problem of inability to align, structure concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

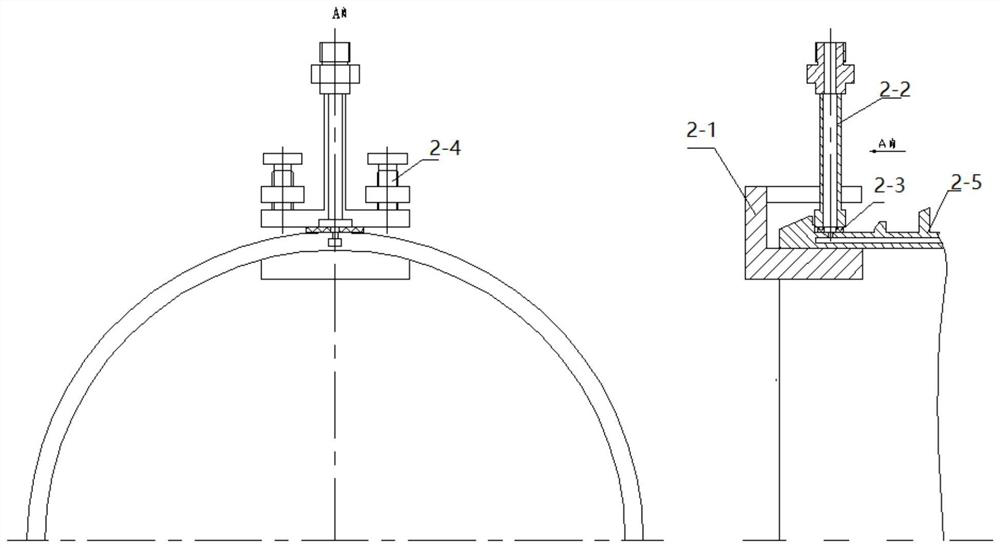

[0023] The flow calibration tool of this embodiment includes a positioning ring 3-1, a pressing ring 3-7, a water inlet device 3-6 and a sealing gasket 3-4.

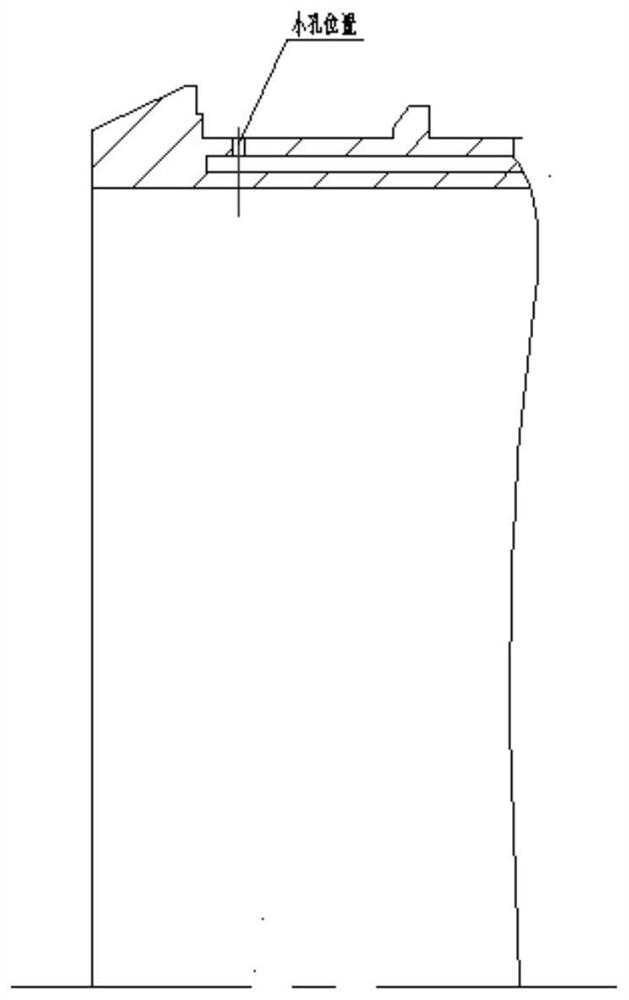

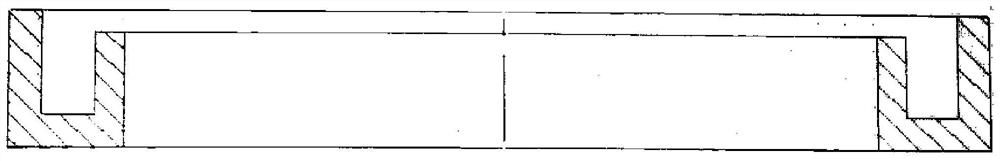

[0024] Among them, such as image 3 As shown, the surface of the product is an elliptical ring, and the positioning ring 3-1 is an elliptical ring (an annular structure consistent with the shape of the product), and an annular groove is processed on one end surface of the product, so that the positioning ring 3-1 includes an inner ring and an outer ring positioning ring 3-1 The outer circumferential surface of the inner ring is aligned with the inner circular surface of the product, and the outer ring is provided with through holes corresponding to the throttle holes on the product surface. The positioning ring 3-1 is provided with a symmetrical center positioning line or an angular position positioning line. During assembly, the positioning line on the positioning ring 3-1 is aligned with the corresponding symmetrical c...

Embodiment 2

[0028] On the basis of embodiment 1, it also includes a slider 3-5 which is adjustable in position in the through hole of the outer ring of the positioning ring 3-1, the slider can move left and right in the through hole, and the center of the slider 3-5 is provided with Threaded hole, water inlet device 3-6 is screwed in the threaded hole of adjustable slide block 3-5 center by thread, as Figure 4 shown. The position-adjustable slide block 3-5 is set in the through hole of the outer ring, which is used to solve the problem that the water inlet device 3-6 and the orifice cannot be aligned due to processing errors of tooling and products. In this embodiment, the slider 3-5 is a T-shaped structure, which can slide slightly in the T-shaped groove on the outer ring of the positioning ring. If the orifice deviates during processing, the water inlet device can also be aligned with the orifice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com