Combined insertion piece

A combined, inserting technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of easy formation of missing stitches, influence on accuracy, easy shaking, etc., to improve the quality of weaving, improve stability, stability Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

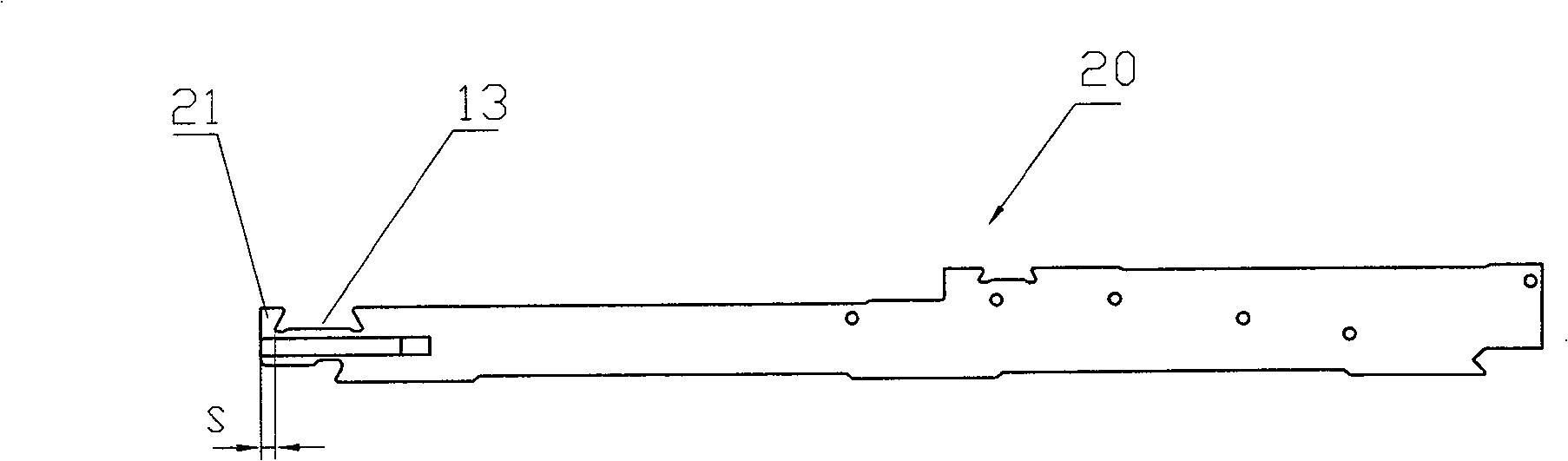

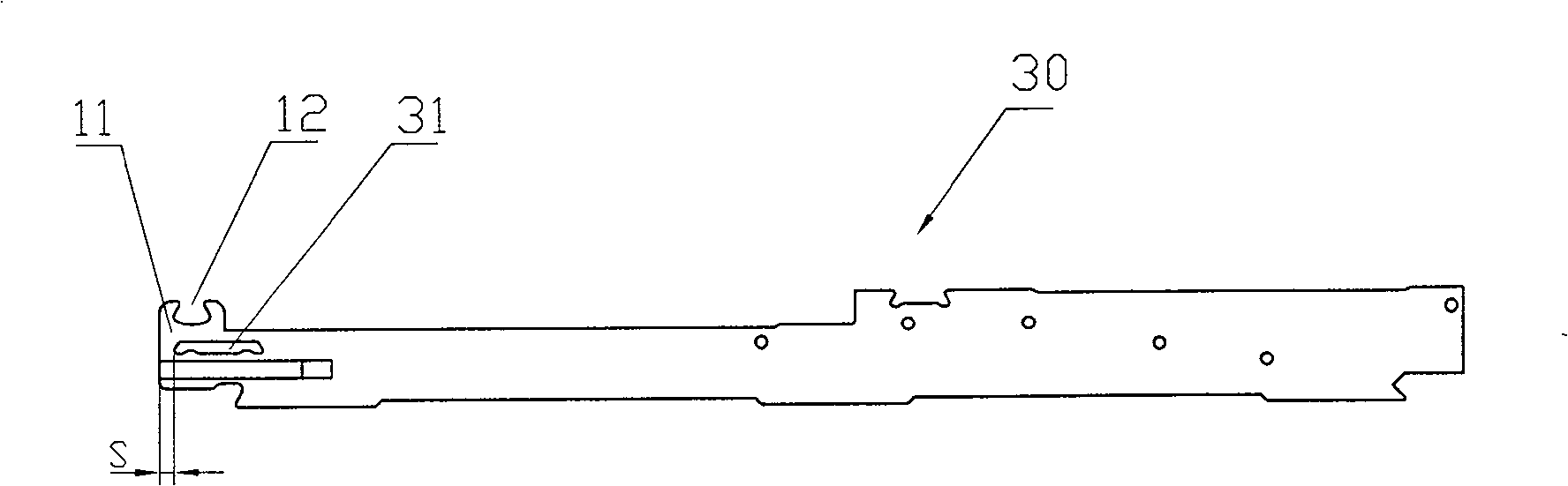

[0018] control figure 1 , the first insert I and the existing ( Image 6 ) of the inserting piece does not have a protruding head compared, and the head is straight, and is provided with a plug iron groove 13 on it. control figure 2 , the second inserting piece II has similar protruding head 11 compared with existing inserting piece, but is a plugging iron hole 31 on the iron groove position of the underside of protruding head 11. In this embodiment, the first insertion piece I and the second insertion piece II are made of 65Mn steel with a thickness of 1 mm. Wherein the spacing S of the front end of the first insertion piece 1 head is implemented by the following three schemes from the front end of the plug iron groove 13 groove bottoms: S=1 millimeter; S=2 millimeter; S=3 millimeter, 13 groove bottoms of the plug iron groove 15mm wide.

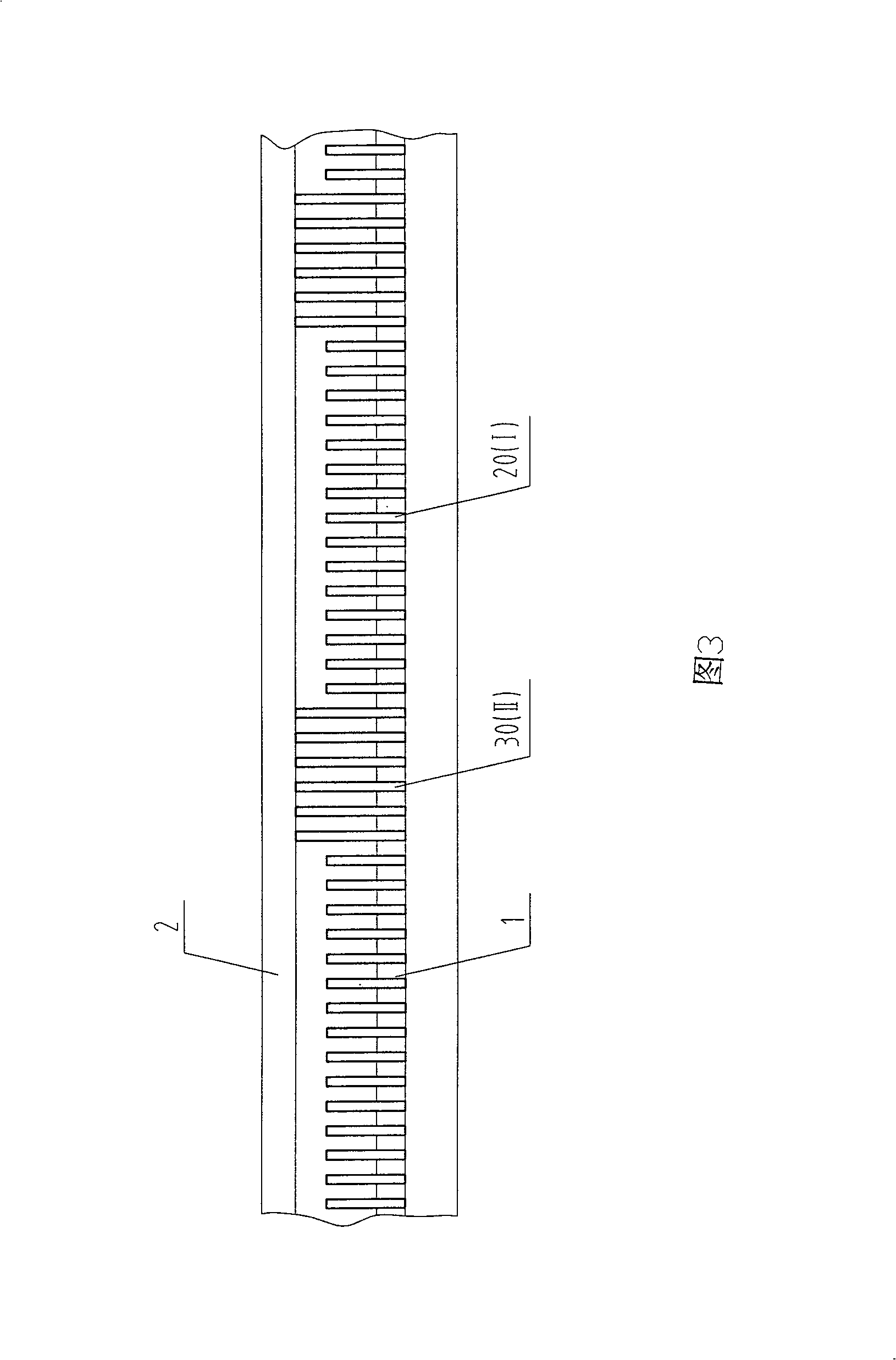

[0019] Comparing with Fig. 3, every 5 pieces of the second insertion pieces II are adjacently arranged and plugged into the slots on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com