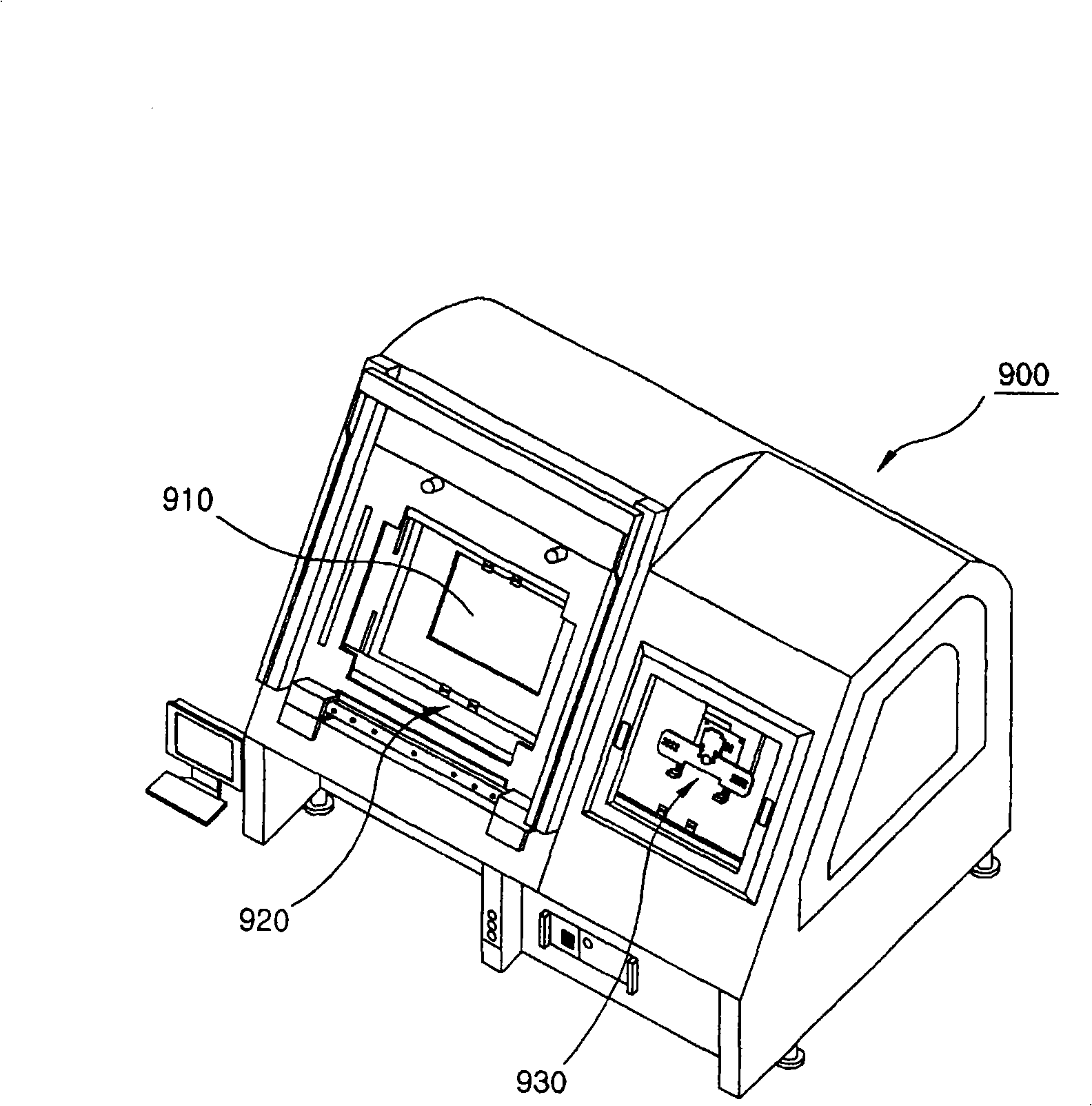

Plane display screen examination device

A technology for inspection devices and display screens, applied in the directions of loading/unloading, transportation and packaging, conveyor objects, etc., can solve problems such as damage to glass display screens, occupation, and complex structure of drive devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

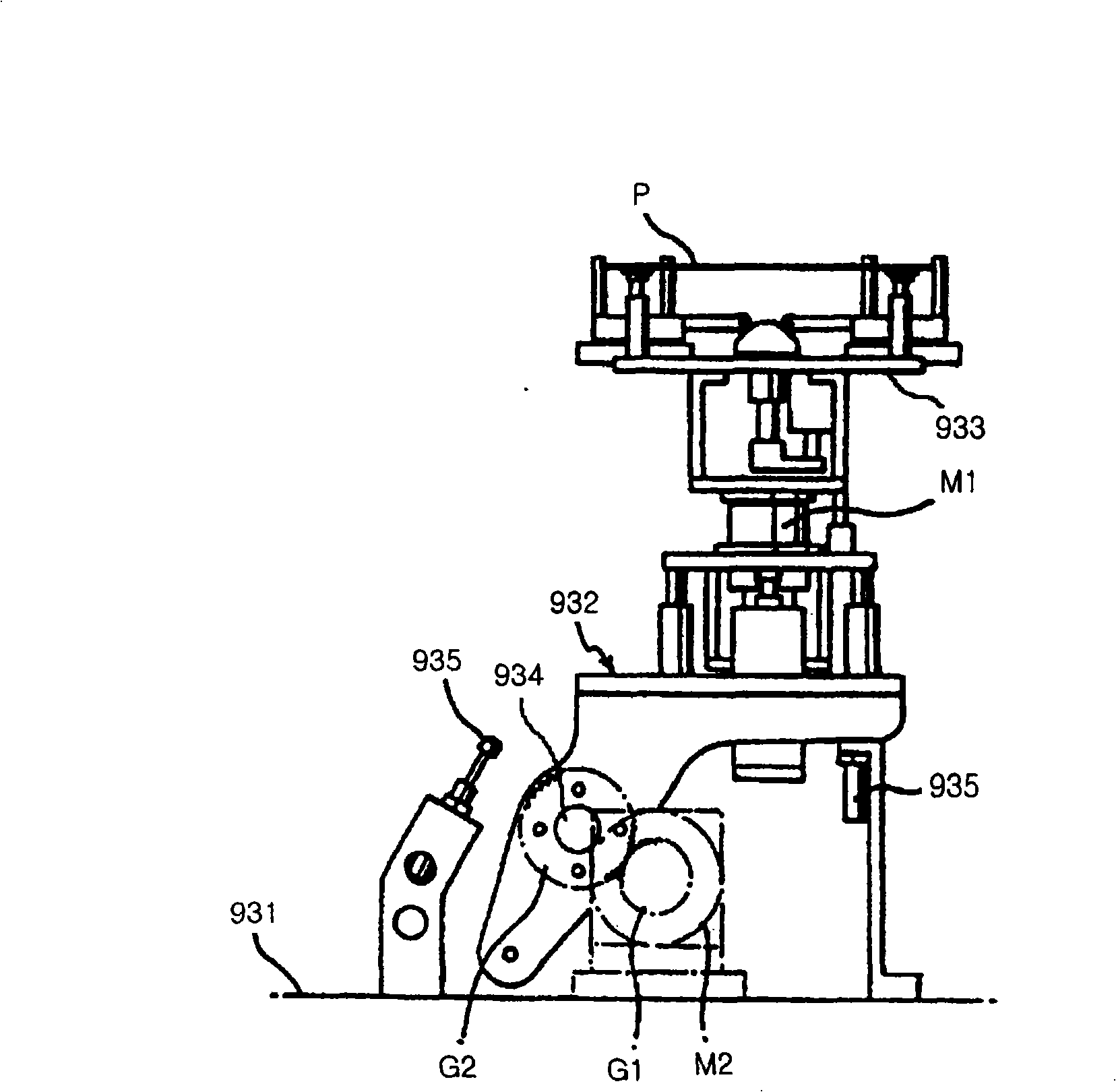

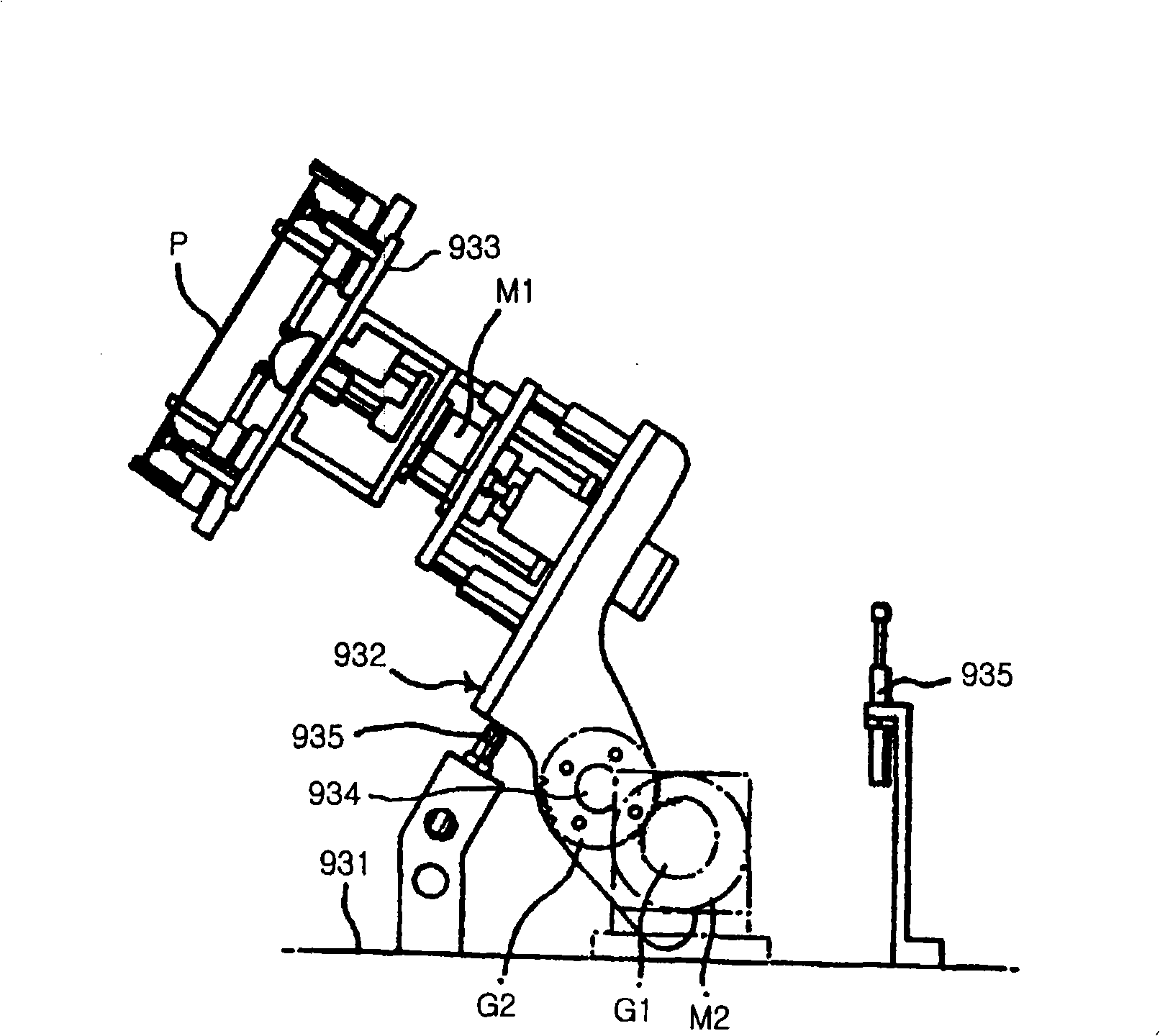

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0040] According to what will be described below, an inspection device according to the present invention also includes: a display screen inspection part, which checks electronic defects of the display screen by applying electric energy to the display screen; a display screen transfer part, which loads the display screen to the display screen On, or unloading, the display screen from the display screen inspection part; and a display screen transfer part, which transfers the display screen to the display screen transfer part.

[0041] Figure 7 A perspective view of the display screen conveying part of the inspection device according to the invention is shown. refer to Figure 7 , the display screen conveying part includes: a frame 20, which is arranged on the base 10, and rotates around hinge shafts 21 on both sides of the frame 20; an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com