System and method for loading and feeding a shotgun

a cartridge and system technology, applied in the field of firearms, can solve the problems of limited ammunition capacity, relative long reloading time, lack of interchangeability, etc., and achieve the effect of facilitating the feeding and/or loading of the cartridg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]While this invention is susceptible to embodiments in many different forms, there are shown in the drawings and will herein be described in detail, preferred embodiments of the invention with the understanding that the present disclosures are to be considered as exemplifications of the principles of the invention and are not intended to limit the broad aspects of the invention to the embodiments illustrated.

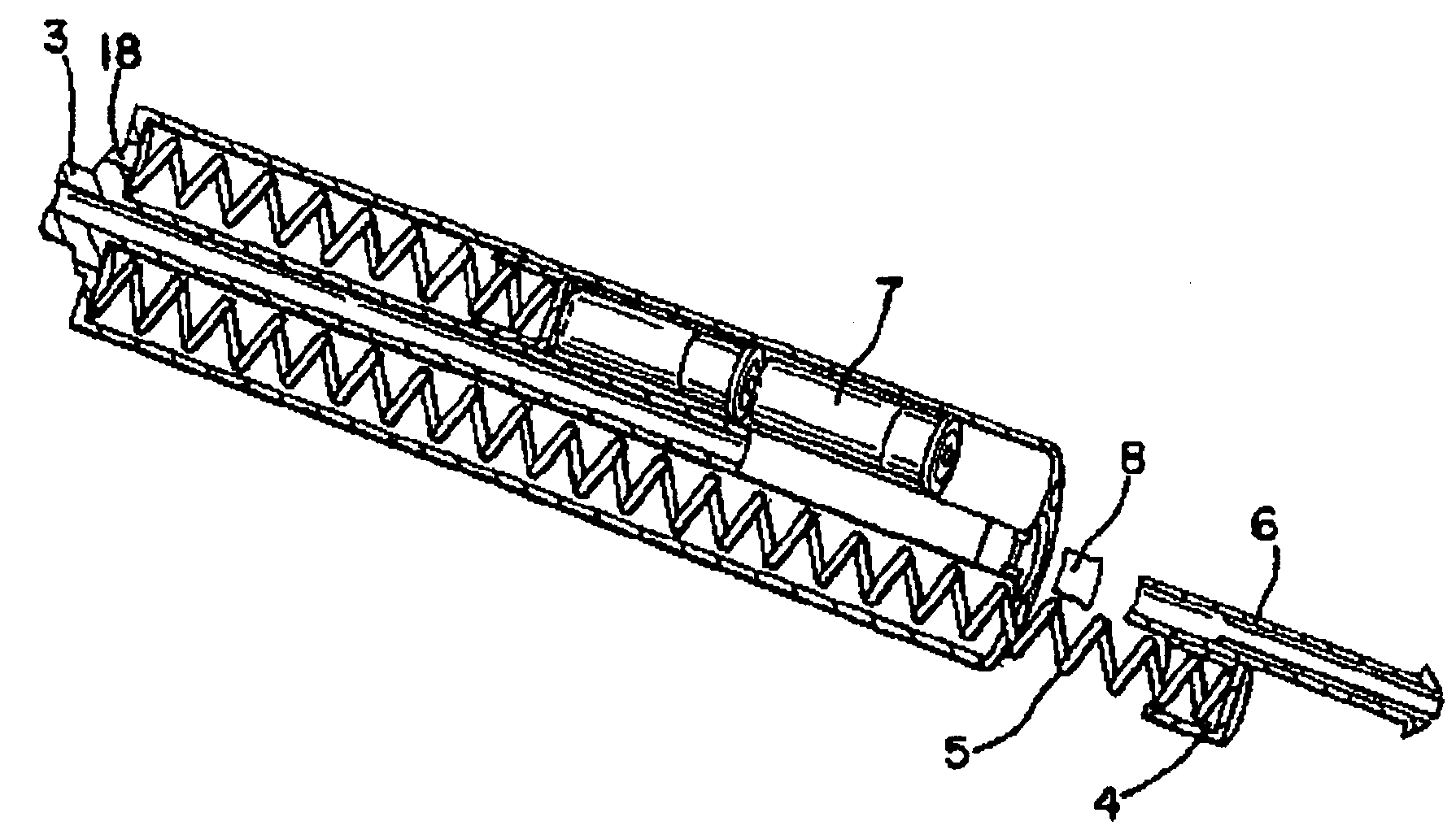

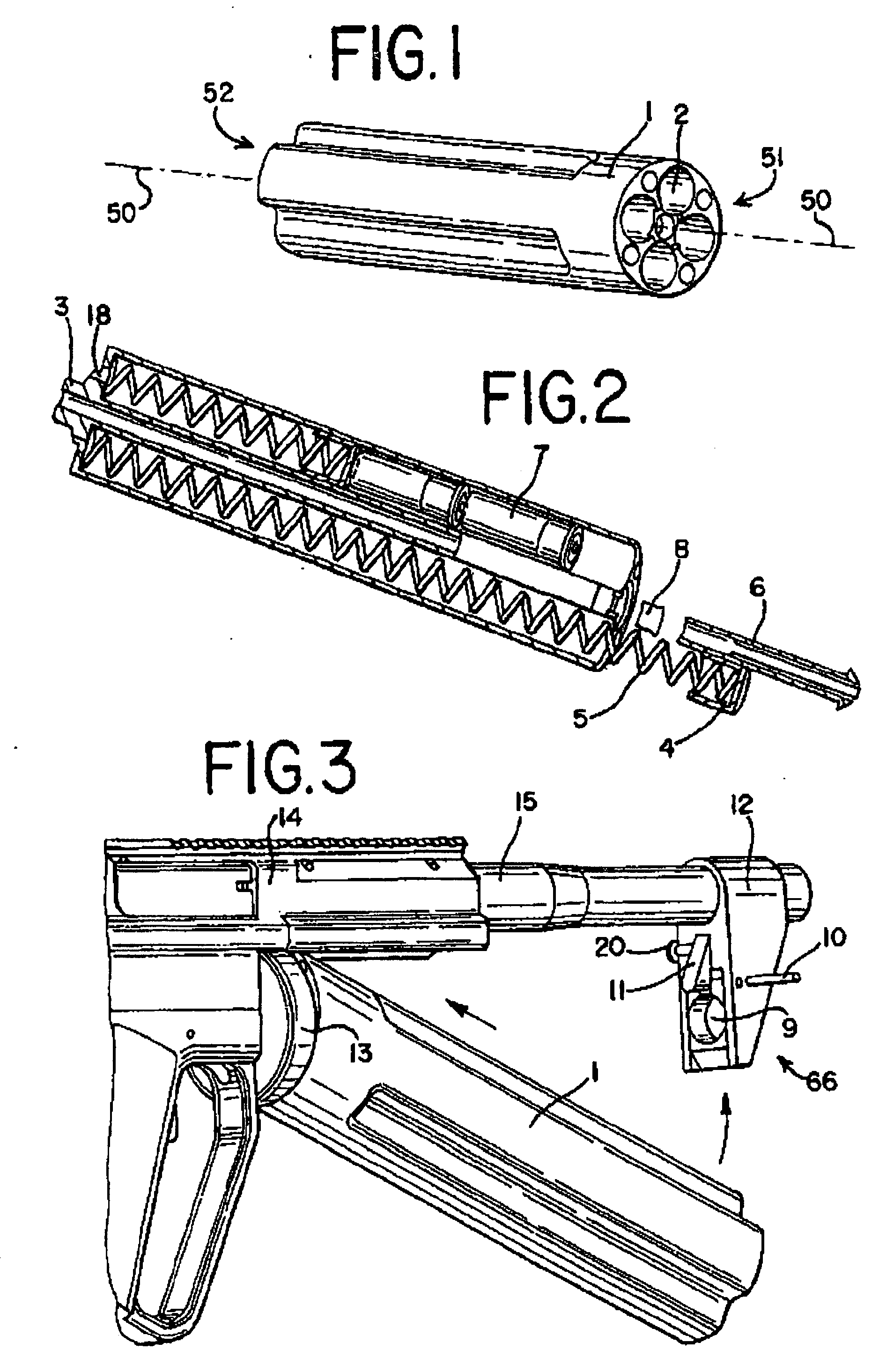

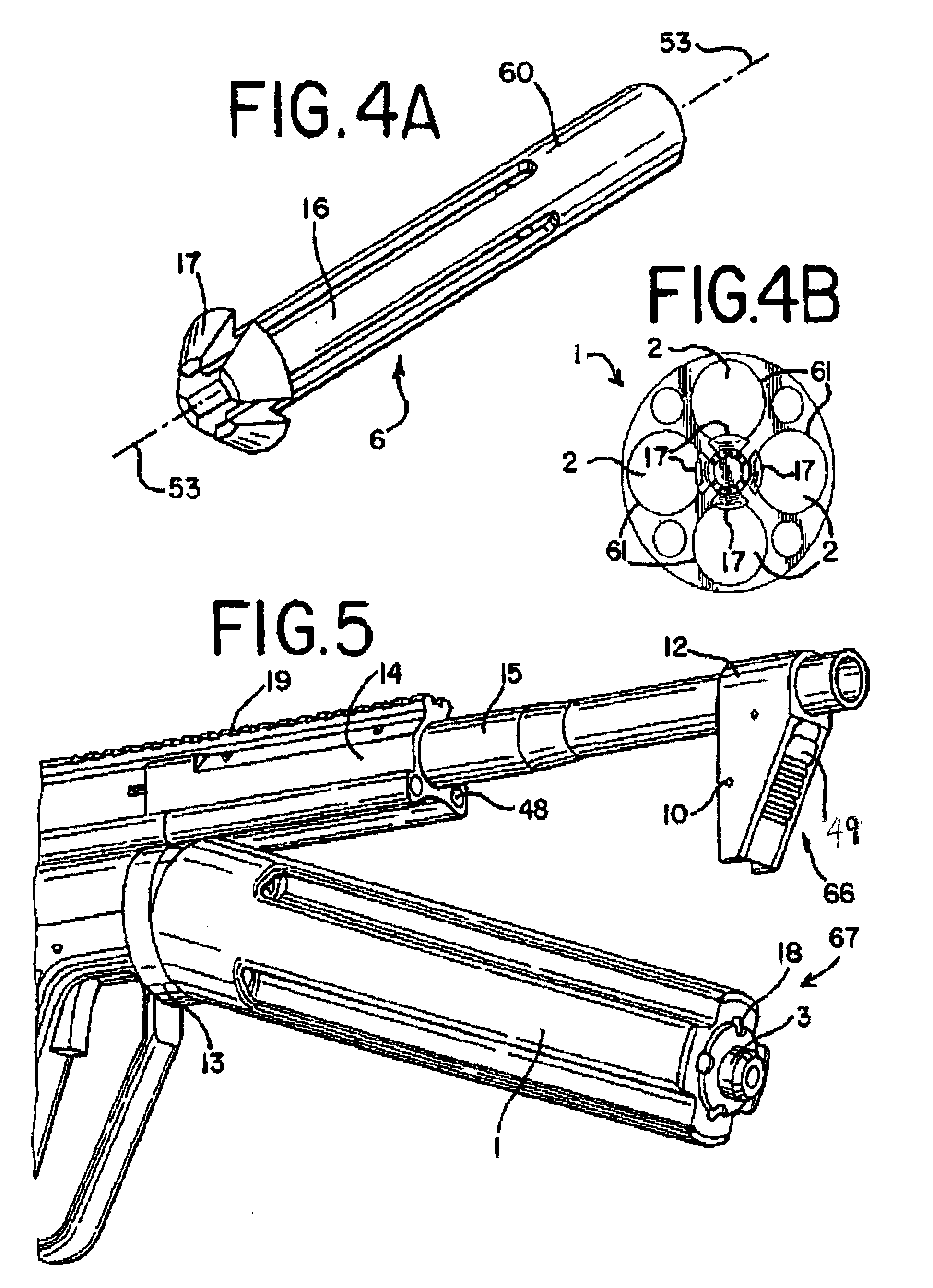

[0039]Referring to the drawings in detail, wherein similar reference characters designate corresponding parts throughout the several views, one embodiment of the present invention shown in FIGS. 1 and 2 is a high-capacity magazine 1 for holding a cartridge 7 for use with a firearm 54 shown in FIGS. 6-9. The firearm 54 includes an actuator 33 operatively connected to a trigger group assembly 65 shown in FIG. 8. The magazine 1 comprises a plurality of tubes 2 being defined within the magazine and axisymmetric about a longitudinal axis 50. Each tube 2 is preferably cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com