Device for stacking and unstacking objects

A stacking and equipment technology, applied in the field of stacking and destacking equipment, can solve the problem that damaged goods cannot always be ruled out, and achieve the effect of improving careful transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

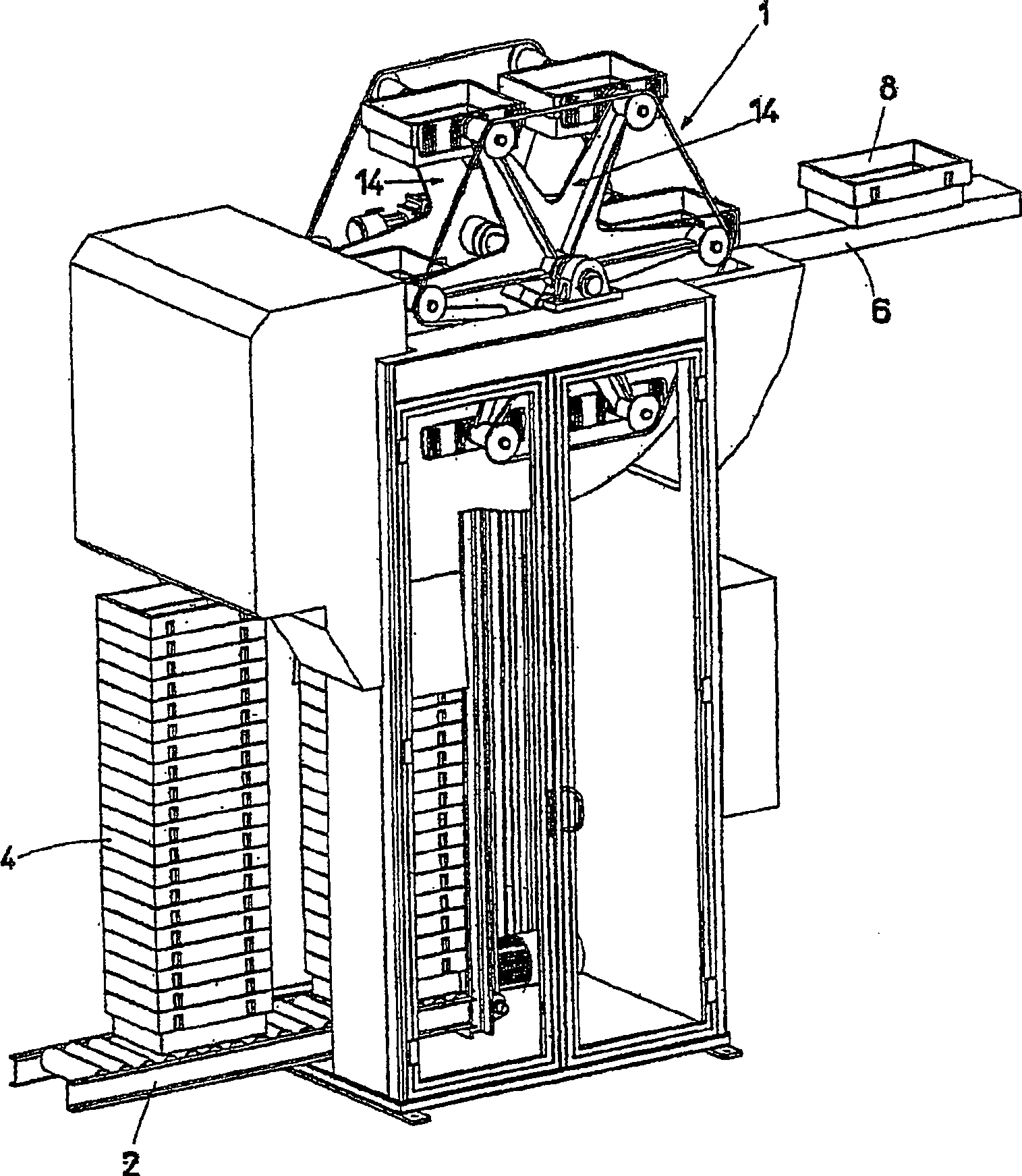

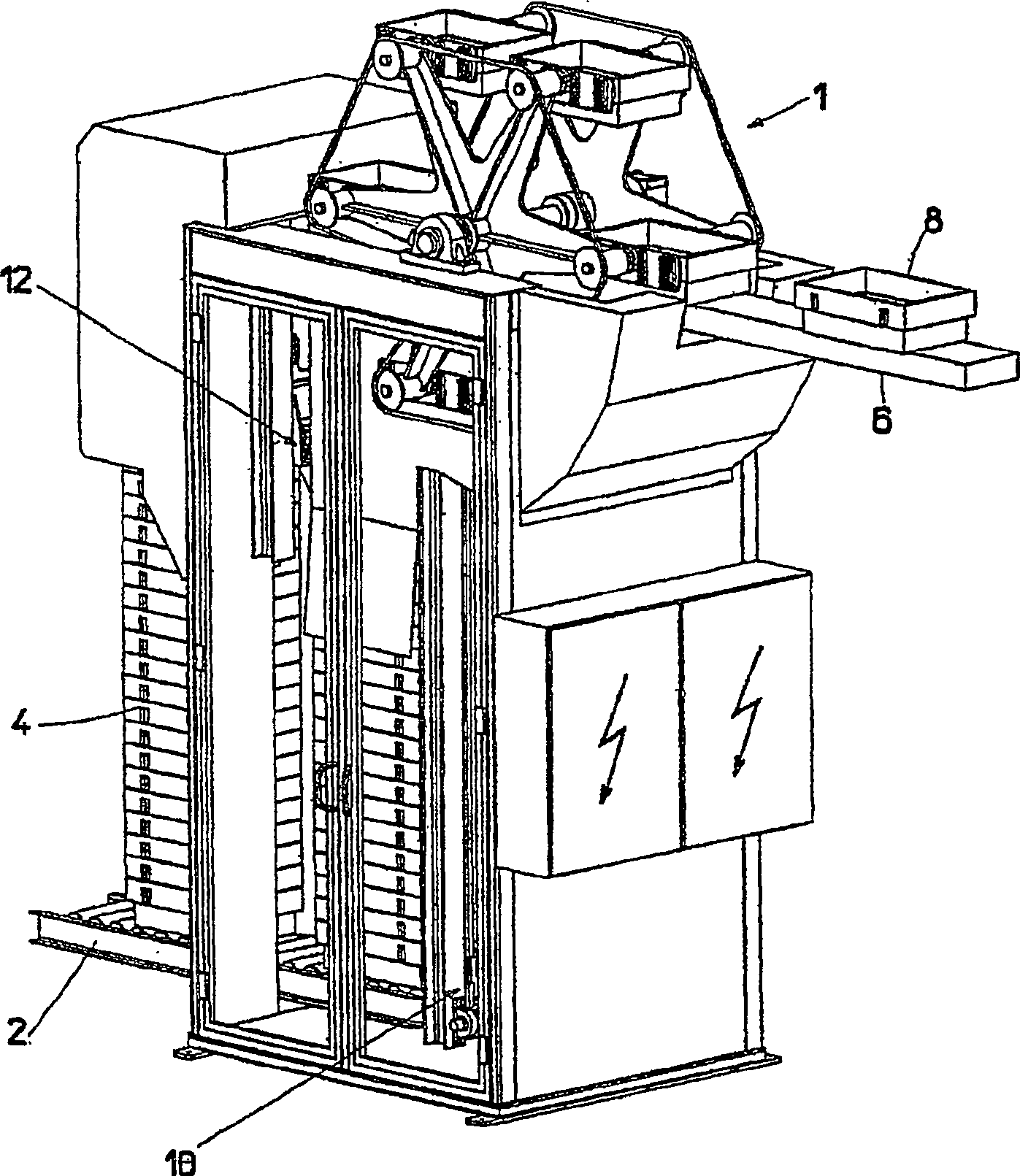

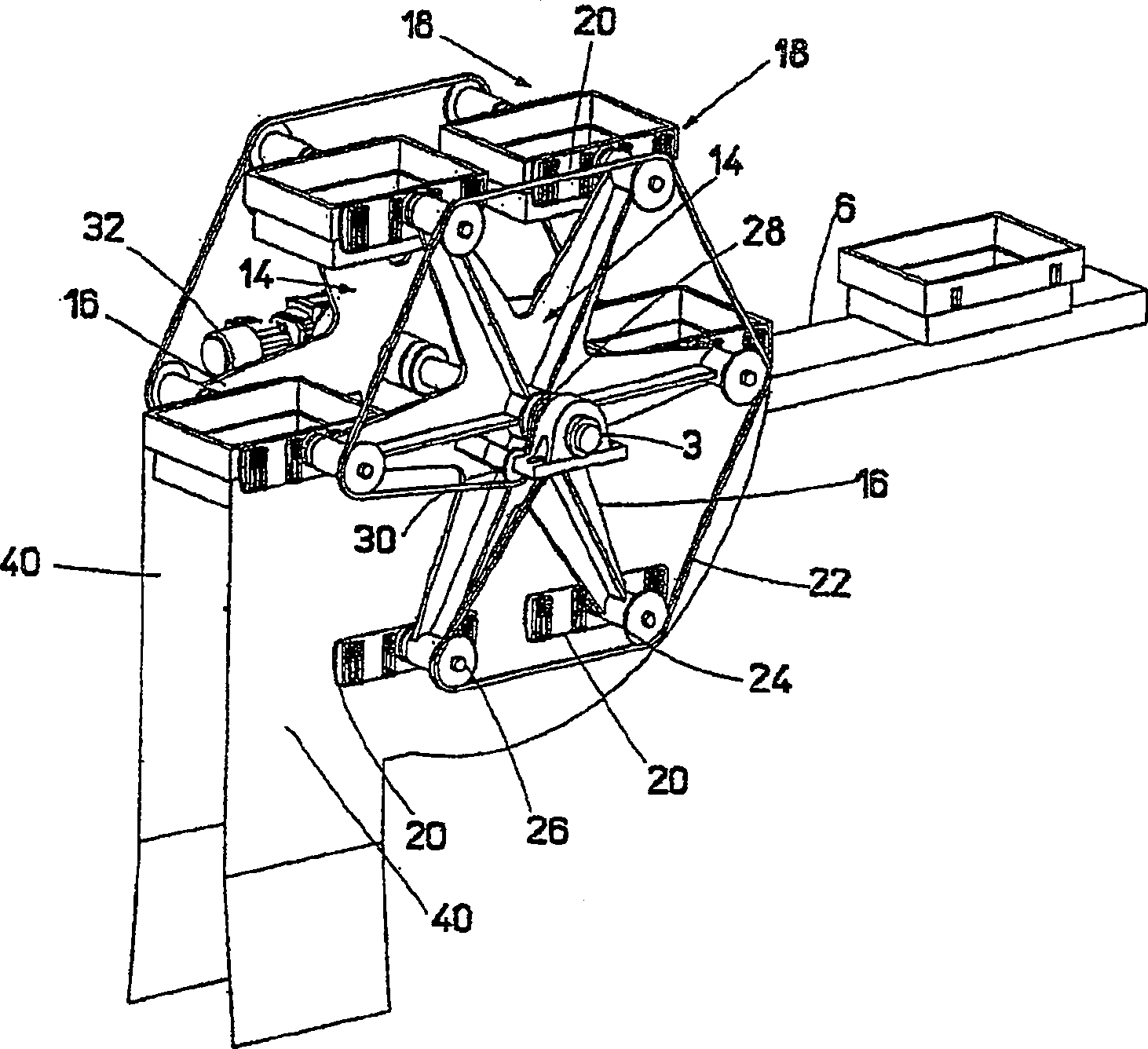

[0035] exist figure 1 with 2 In the embodiment represented in, by the equipment of the present invention has its stacking wheel 1, be arranged on the conveyer belt 2 that is used to carry in or carry out case pile 4 be one side and be used for carrying in or carry out the conveying of individual case 8 Device 6 is between the other party. In addition to the stacking wheel 1 that will be described in detail later, this equipment is also at the end of the conveyor 2 for input or output box stacks 4, and there are two alternately working lifting devices ( figure 2 with 4 ) for lifting the case stack 4 to such an extent that the topmost case of the case stack 4 is always placed in the extraction position.

[0036] It should also be pointed out in this respect that in this embodiment the conveyor belt 6 that is used to separate into individual boxes is located at the height of the axis of the stacking wheel 1, but it can also be located at a higher position so that it is next t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com