Protective agent for increasing stability of alpha-galactosidase prepared by aspergillus ZU-G1 foetidus fermentation and application thereof

A technology of galactosidase, ZU-G1, applied in the direction of enzyme stabilization, enzymes, enzymes, etc., can solve the problems of lack of theoretical basis for the effective application of liquid α-galactosidase preparations, few research reports on enzyme stability, etc. , to achieve the effect of improving the maximum efficiency, easy to use on a large scale, and broadening the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Production of α-galactosidase crude enzyme liquid by liquid fermentation of Aspergillus futidatus ZU-G1

[0026] According to the method disclosed in the Chinese invention patent application 200610050135.4, 30 ml of fermentation medium is filled in a 250 ml Erlenmeyer flask, and 1 ml of Aspergillus foetidus ZU-G1 spores (concentration of 1 × 10 6 individual / ml), the α-galactosidase fermentation broth obtained after culturing for 96 hours at 28° C. on a shaker with a rotational speed of 200 rpm. The fermented liquid was centrifuged for 15 minutes with a refrigerated centrifuge, and the rotating speed was 8000 rpm. The supernatant was collected and graded and salted out with ammonium sulfate (ammonium sulfate saturation 20%-70%), then the precipitate was collected and washed with a small amount of 0.2mol pH5.0 / L disodium hydrogen phosphate-citric acid buffer solution, put it into a dialysis bag, and dialyze with distilled water for several hours (4°C), until no...

Embodiment 2~10

[0028] Add the protective agent of the present invention in the crude enzyme liquid (enzyme activity about 100U / ml) that obtains in embodiment 1; The use ratio of mannitol, trehalose and raffinose in every 100ml crude enzyme liquid is shown in Table 1, crude enzyme liquid After adding the protective agent of the present invention, put it in a water bath at 60° C. for 1 hour, then immediately in an ice bath, and measure its enzyme activity after diluting 100 times. Among them, trehalose is produced by Shanghai Yuanju Biotechnology Co., Ltd.; mannitol is produced by Guangdong Taishan Chemical Factory; and raffinose is produced by American Amresco.

[0029] Table 1

[0030]

Example Trehalose

(mg / 100ml

crude enzyme solution) Mannose

(mg / 100ml

crude enzyme solution) Raffinose

(mg / 100ml

crude enzyme solution) Enzyme activity retention *

(%) 2 37.8 18.22 75.6 67.95 3 37.8 27.33 100.8 72.71 4 37.8 36.44 126 64.19 ...

Embodiment 11

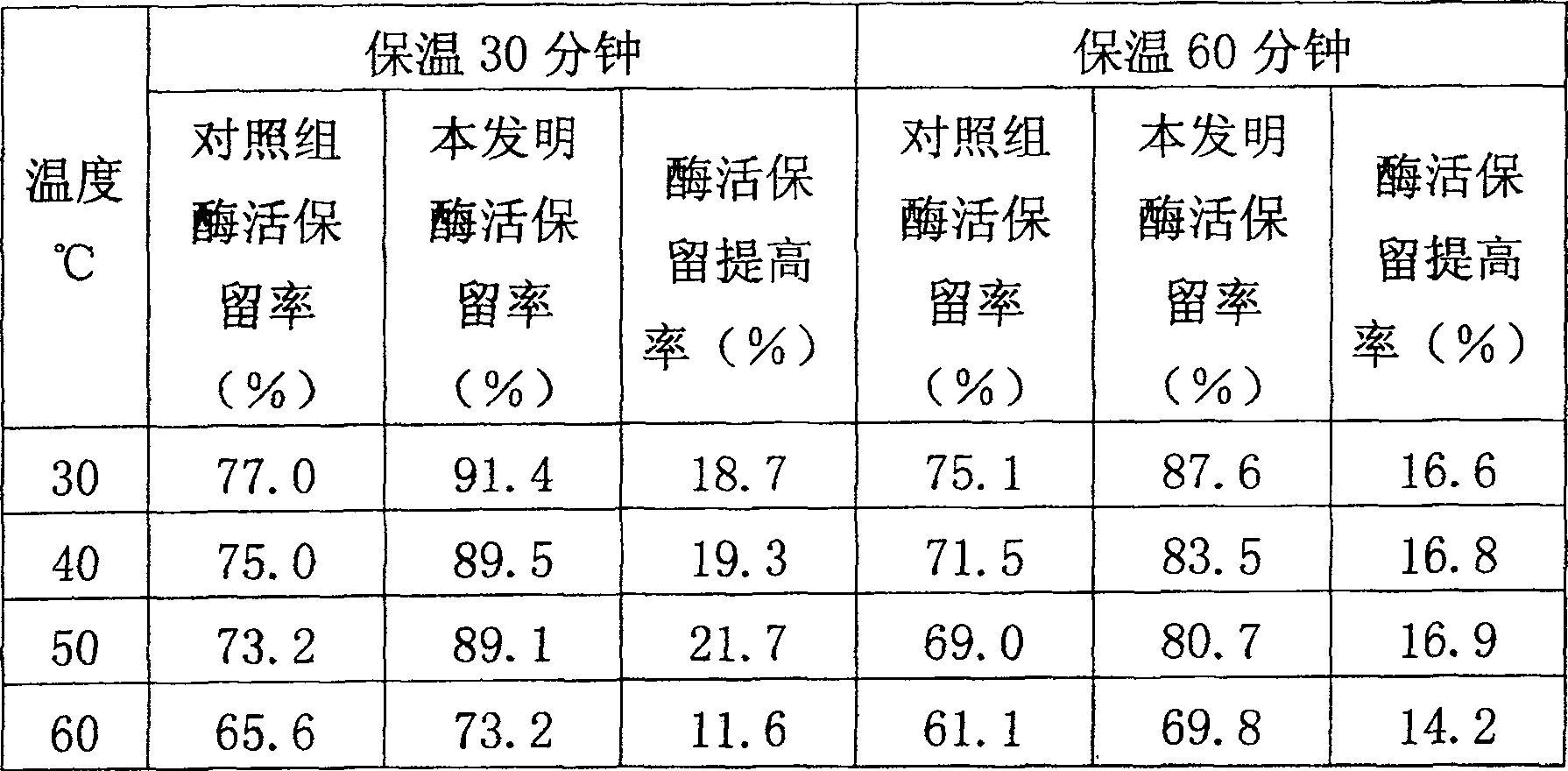

[0033] Example 11 Experiment of using the protective agent of the present invention to improve the thermal stability of α-galactosidase under different temperature conditions

[0034] The α-galactosidase produced by liquid fermentation of Aspergillus foetidus ZU-G1 added with a protective agent and the control group without a protective agent were calculated as 100% of the enzyme activity retention rate without heat treatment and without a protective agent placed at 4°C. The enzyme activity retention rates obtained after heat treatment at different temperatures for different times were compared. In this experiment, 27mg of mannitol, 66mg of trehalose and 101mg of raffinose were added to every 100ml of crude enzyme solution. The specific results are shown in Table 2.

[0035] Table 2

[0036]

[0037] After adding the protective agent of the present invention to the crude enzyme solution, put it in a water bath at 60°C for 1 hour, then immediately ice-bath it, and measure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com