Barrel casing pump and method for manufacturing barrel casing pump

A shell and sheath technology, which is applied to components of pumping devices for elastic fluids, engine manufacturing, pumps, etc., can solve problems such as increased manufacturing costs, and achieve the effects of low manufacturing and easy cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

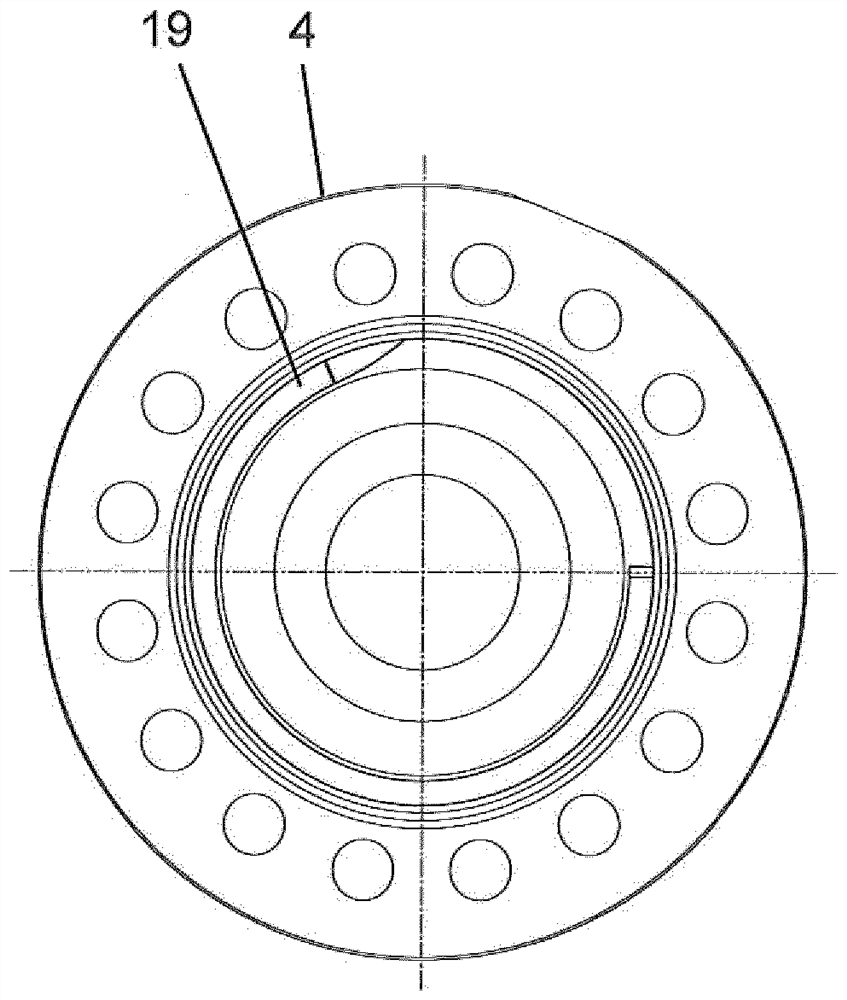

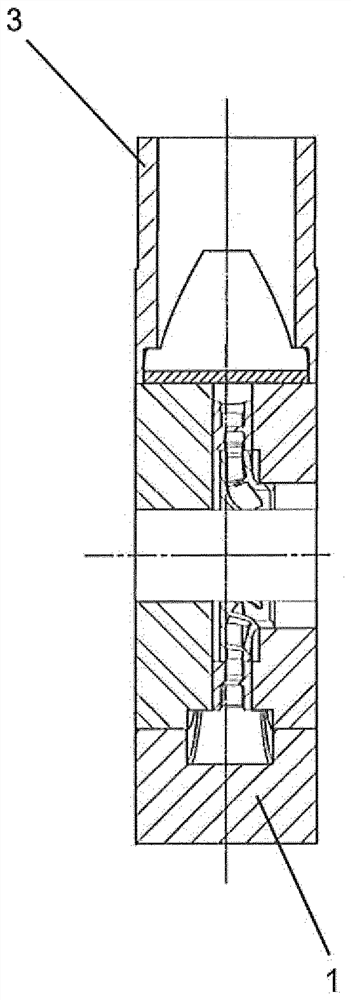

[0031] figure 1 A rotary pump is shown with a jacket housing 1 which has both a suction connection 2 and a pressure connection 3 . The jacket housing 1 is closed at its pressure-side end by a cover 4 , which is fastened, in particular screwed, to the jacket housing 1 by means of connecting means 5 .

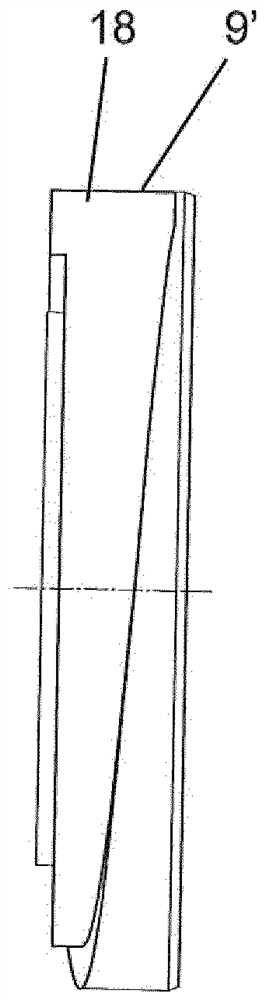

[0032] Arranged in the jacket housing 1 is an insert having a shaft 6 arranged rotatably about an axis A of rotation. A plurality of impellers 7, 7' are arranged one behind the other on the shaft 6, whereby individual pump stages, here five pump stages, are formed. Each pump stage additionally has a stationary guide wheel 8, wherein the last guide wheel seen in the direction of flow is designated with the reference numeral 8'. The closest impeller to the pressure connection 3 or, seen in the direction of flow, the last impeller is marked with the reference numeral 7'. Said working wheels 7, 7' are radial wheels in this embodiment. As an alternative, for example, semi-axial wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com