Roller mill

A technology of roller mill and grinding table, which is applied in the field of roller mill, can solve the problems of large distance, achieve the effect of simple installation and disassembly, and reduce the overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

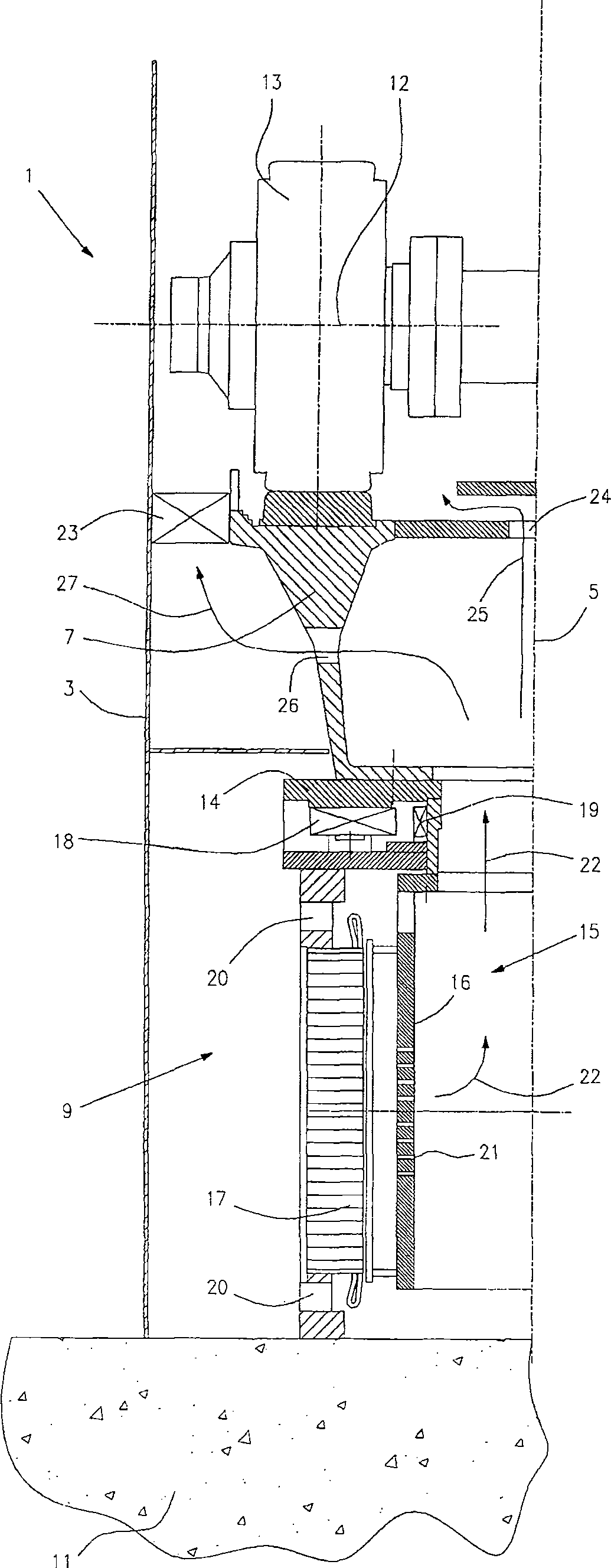

[0008] The figure shows a cross-sectional view of a roller mill 1 comprising: a housing 3 surrounding a grinding table 7 rotatable about a vertical axis 5 , said grinding table being supported by a machine base 11 via a support 9 at least one roller 13 rotatable about a substantially fixed axis 12 designed to interact with the grinding table 7 ; and an electric motor 15 comprising a rotor 16 firmly connected to the grinding table 7 and a stator 17 .

[0009] According to the invention, the stator 17 forms an integral part of the support 9, which also comprises: a slip ring 14, to which the grinding table 7 is fixed; a thrust bearing 18, when the grinding table 7 rotates during operation of the roller mill, A slip ring 14 moves on a thrust bearing 18 ; and a radial bearing 19 , which controls the radial movement of the grinding table 7 . Thus, the entire support 9 constituting the motor can be installed and replaced as a unit, while at the same time the unit tilting moment abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com