Fixture mold for preparing integral connection structure

A connection structure and integrated technology, applied in the direction of structural parts, electrical components, circuits, etc., can solve the problems of increasing quality hidden dangers, increasing production processes, etc., and achieve the effect of avoiding secondary connection processes and avoiding operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

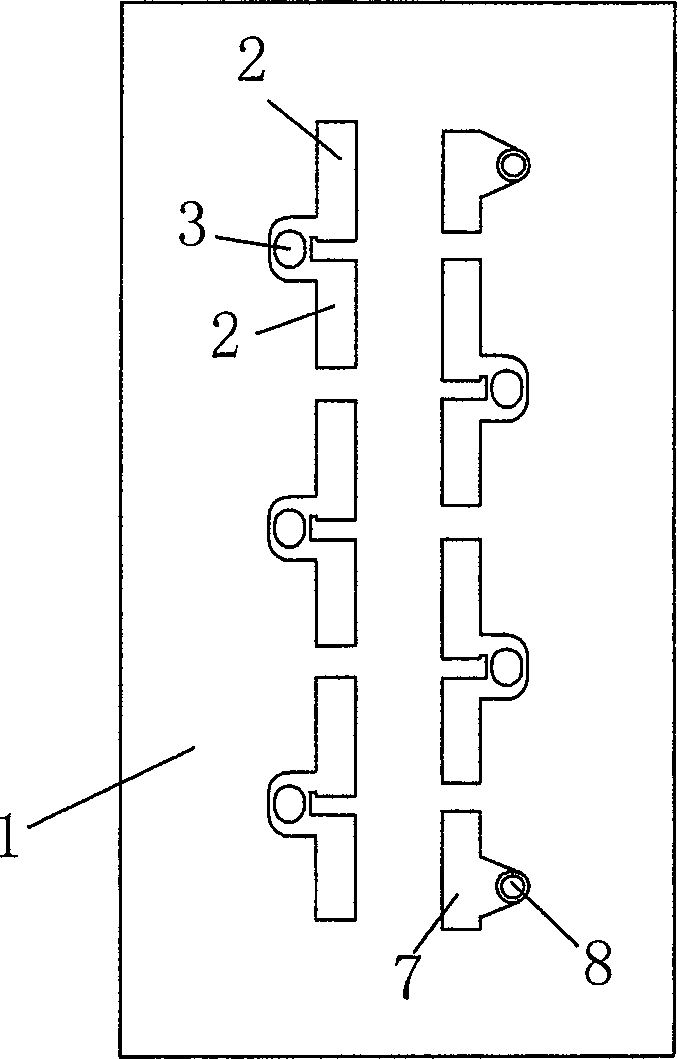

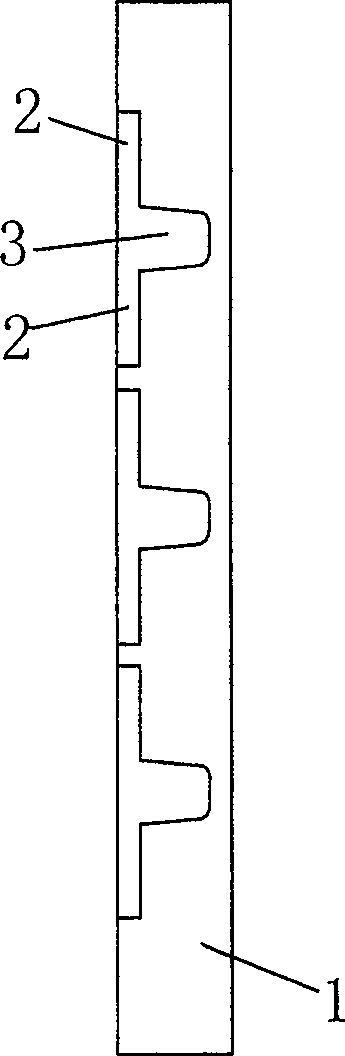

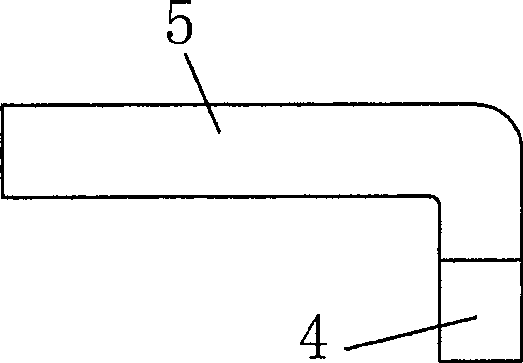

[0019] An integrated connection structure for the connection between battery cells, including a battery composed of at least two cells in series, each cell consists of a plurality of positive and negative plates stacked alternately, and a separator separating the positive and negative plates The tabs of the positive and negative plates of the monomer are respectively connected to two bus bars. Each cell is separately installed in the cell in the battery case, and the negative electrode bus bar on the previous cell is connected to the positive electrode bus bar on the next cell through a connecting piece. In the present invention, the two interconnected bus bars The row and the connector connecting the two busbars are integrally cast and formed, and the three are connected in an integrated structure. Through this one-piece connection structure, the connection between the monomers is completed at the same time when the two busbars are respectively welded to the pole plates of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com