Hydro-pneumatic spring independent suspension and heavy-duty car adopting the suspension frame

A technology of oil-pneumatic springs and independent suspensions, which is applied in the direction of elastic suspensions, suspensions, vehicle components, etc., can solve the problems of small frame height adjustment range, large vehicle bias frequency, etc., to improve handling stability and occupy lateral space Less, the effect of improving driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

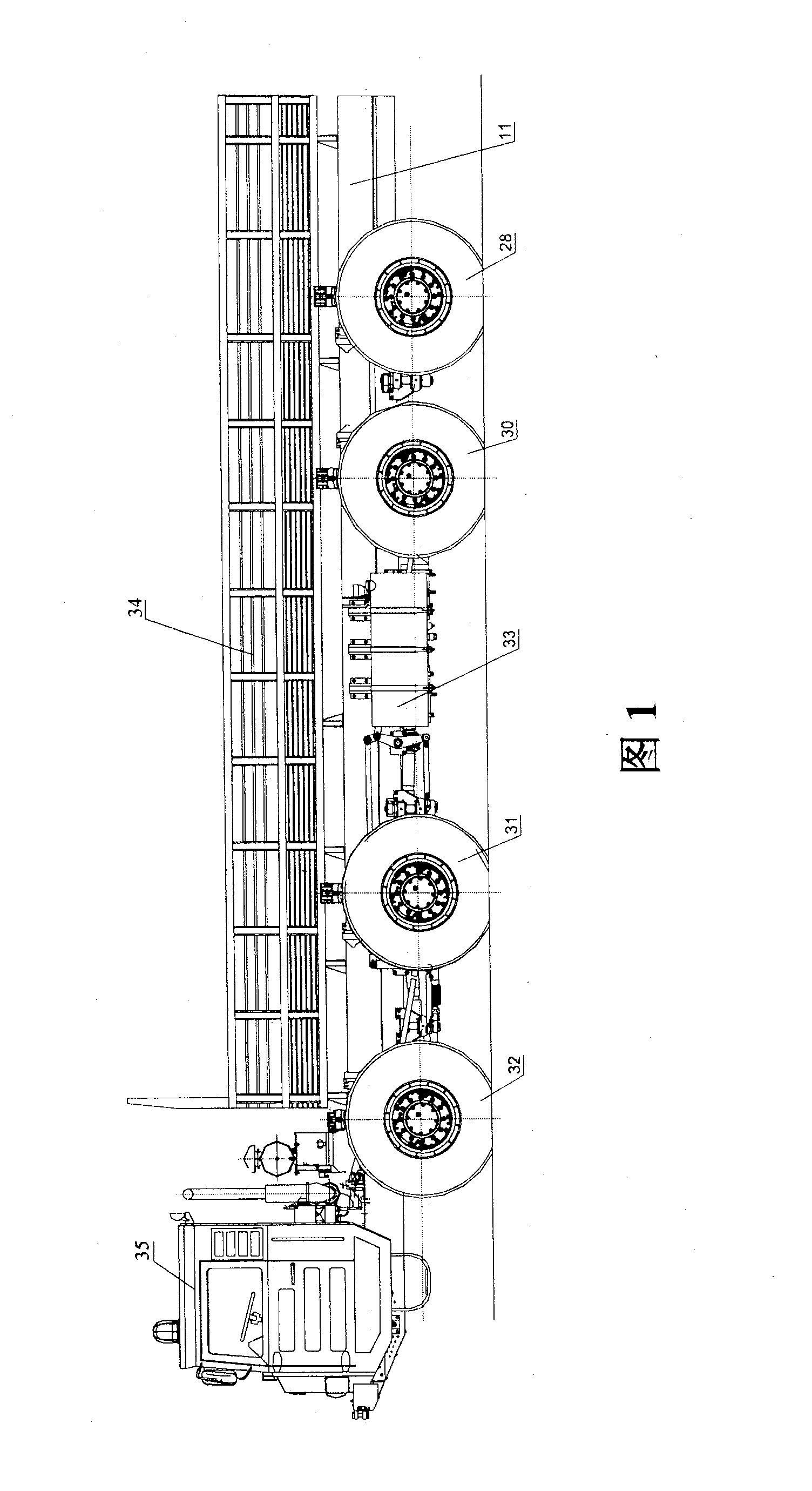

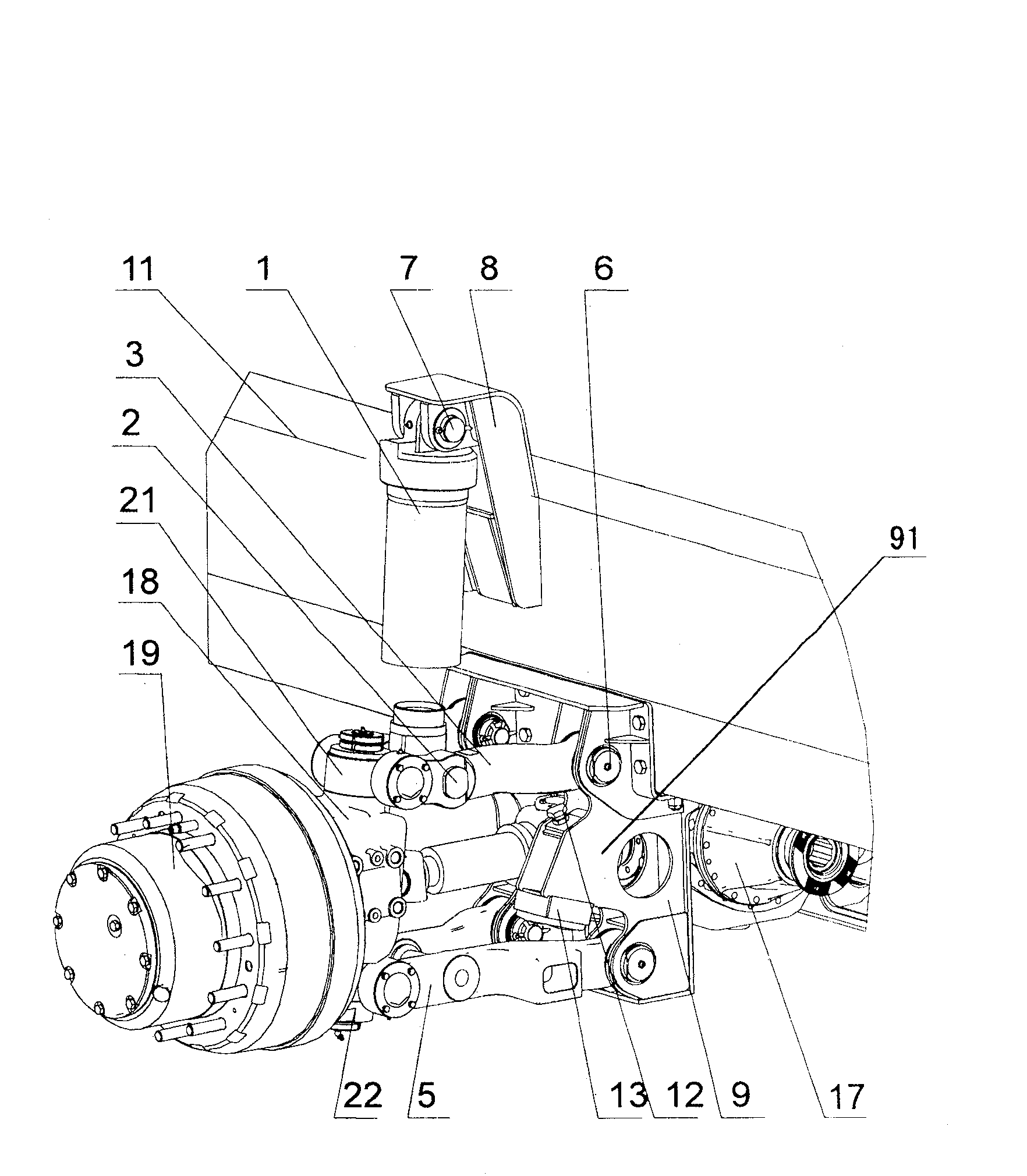

[0041] figure 1 For adopting the side view of the four-axle automobile of the present invention; figure 2 It is an axonometric view of the present invention;

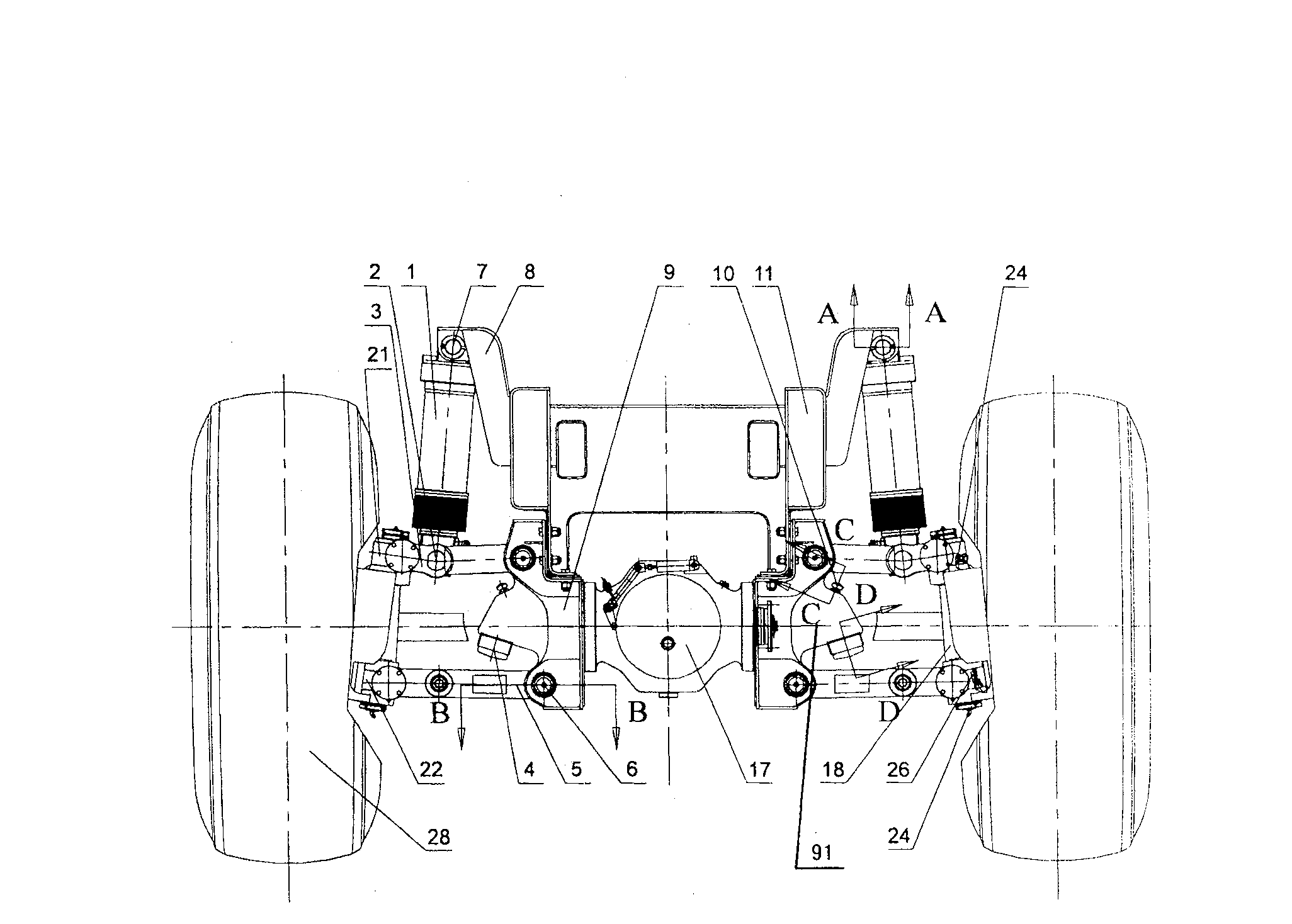

[0042] image 3 It is the rear view of the present invention; Figure 4 It is A-A sectional view of the present invention; Figure 5 It is a B-B sectional view of the present invention; Figure 6 It is a C-C sectional view of the present invention; Figure 7 It is a D-D sectional view of the present invention.

[0043] figure 1 Shown, adopt four-axle heavy-duty vehicle of the present invention, comprise cab 35, vehicle frame 11, container 34, fuel tank 33 and wheel 28,30,31,32; Wheel is fixed on the wheel group 19.

[0044] The left and right sides of each drive axle 17 are respectively installed on a set of suspension devices that act independently on the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com