Thermal fan without inverse flow characteristic

A heat dissipation fan without backflow technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve the problem that the heat dissipation effect of the heat dissipation fan 1 is damaged and the air flow cannot be effectively and smoothly Circulation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

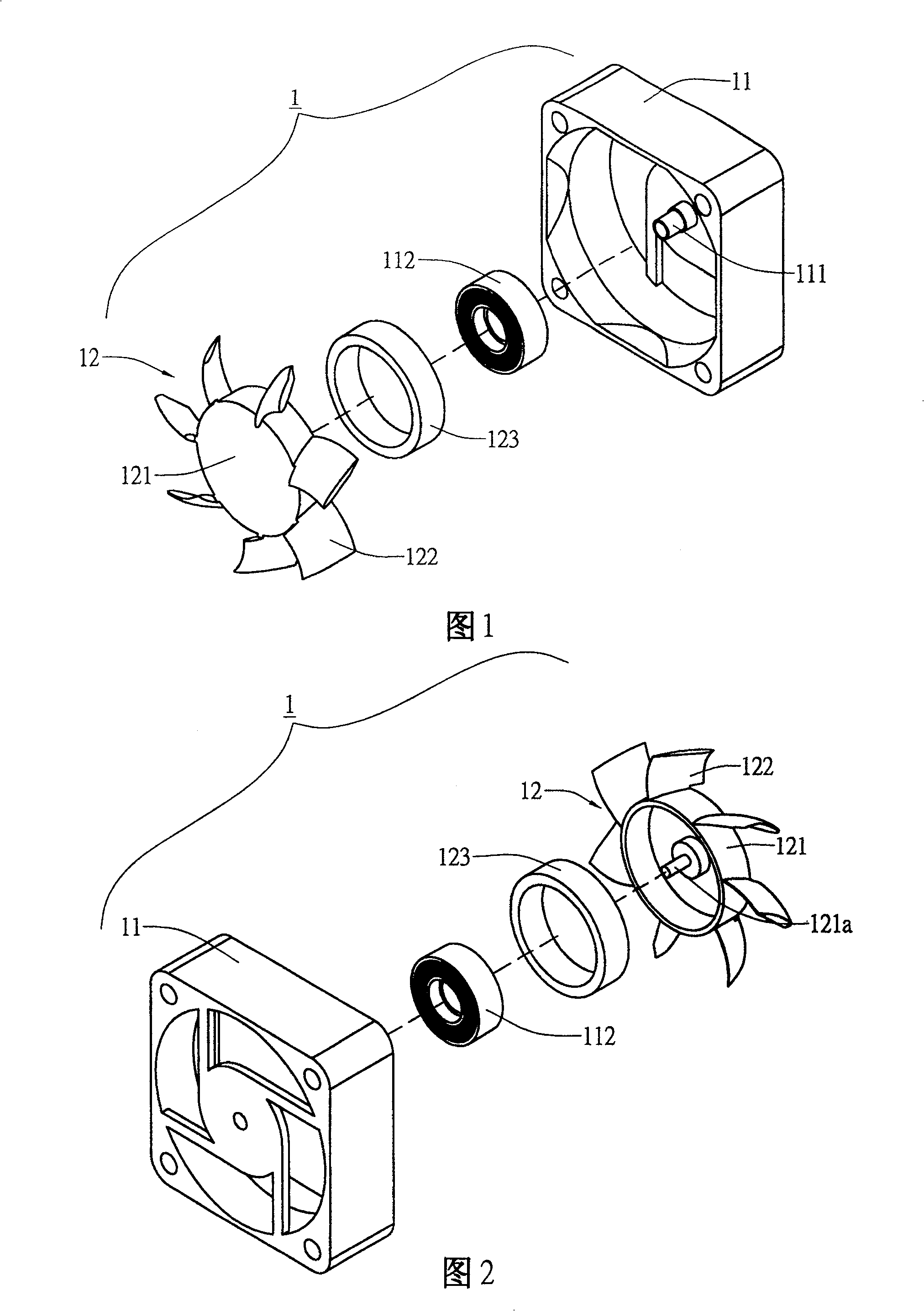

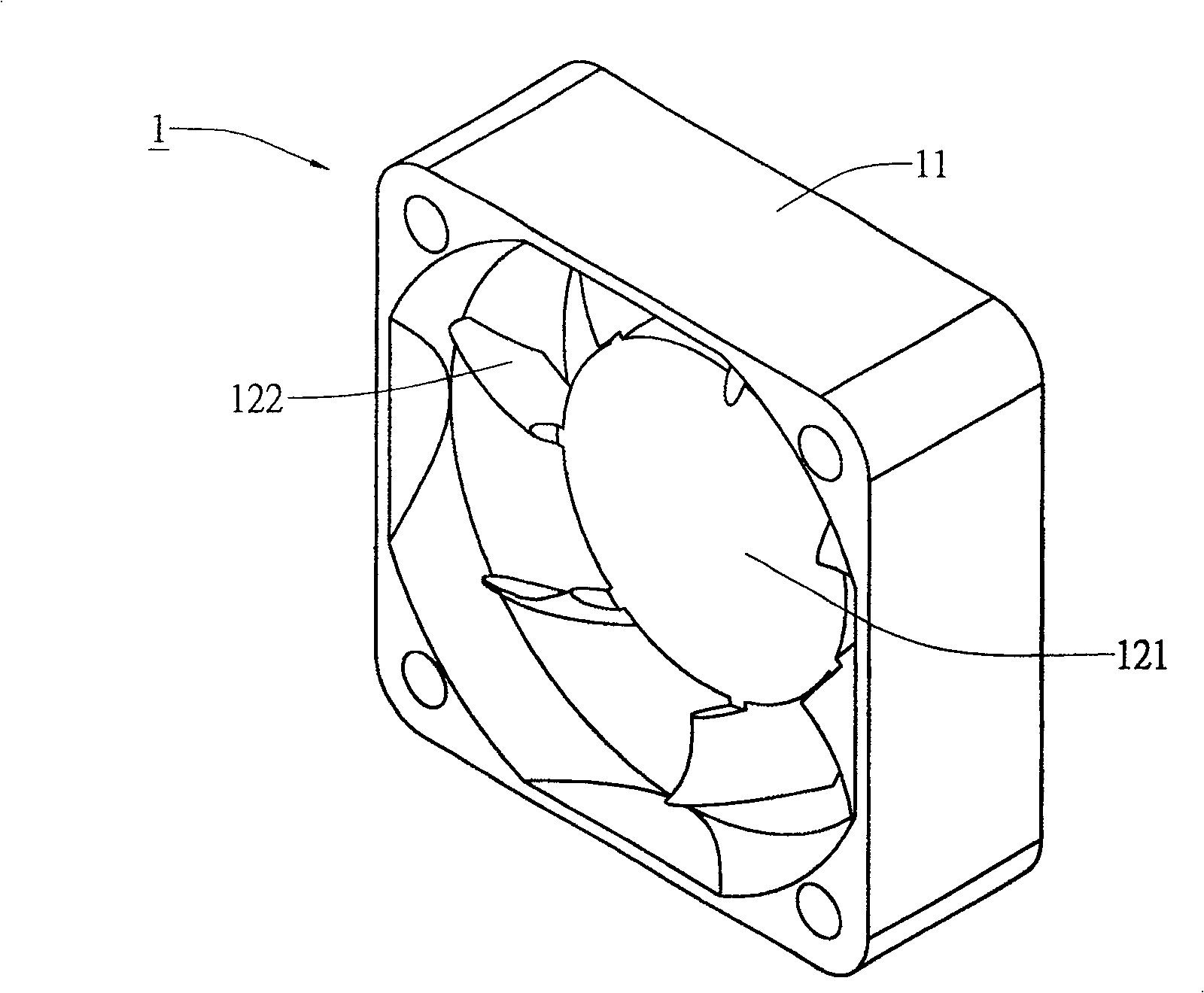

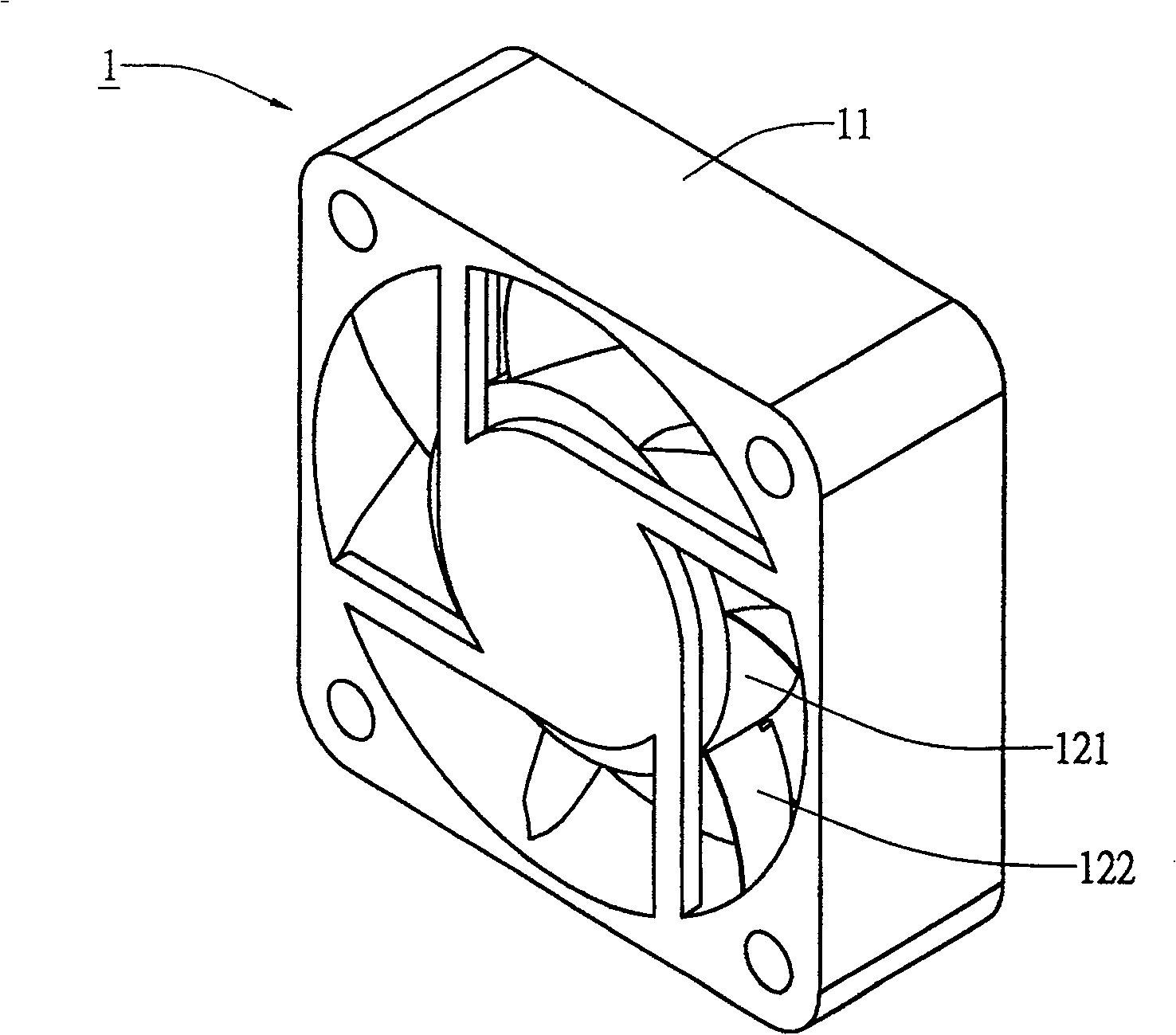

[0073] The present invention is a cooling fan without backflow characteristics, please refer to Figure 6 to Figure 9 In the first embodiment of the present invention shown, the cooling fan 2 is composed of a motor stator 21, a frame 22, a motor rotor 23, and fan blades 24; wherein the bearing sleeve 211 of the motor stator 21 is provided with a coil 212, And combined with the air inlet side 221 of the frame 22 by the support structure 222, the motor rotor 23 has a receiving portion 231, and a magnet 232 is assembled, wherein the fan blade 24 is assembled on a central portion 241, the The central portion 241 is rod-shaped, and a fixed portion 25 is formed at one end of the central portion 241 , and the fixed portion 25 can be an axis.

[0074] Connect the fixed part 25 of the fan blade 24 to the receiving part 231 of the motor rotor 23, so that the fan blade 24 is joined to the motor rotor 23, and the motor rotor 23 with the fan blade 24 assembled on the motor The bearing sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com