Method of Ditching and Ditching in Internal Dumps Contribute to Stope Ventilation in Near-horizontal Open-pit Coal Mine

A technology for open-pit coal mines and internal dumping, which is applied in the mining of open-pit mines, ventilation of mines/tunnels, mining equipment, etc. Worker working environment, increase air flow area, reduce dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0028] The method for leaving ditch and discarding in the inner dump site of the present invention, which is conducive to the ventilation of the stope of the near-level open-pit coal mine, its steps are as follows:

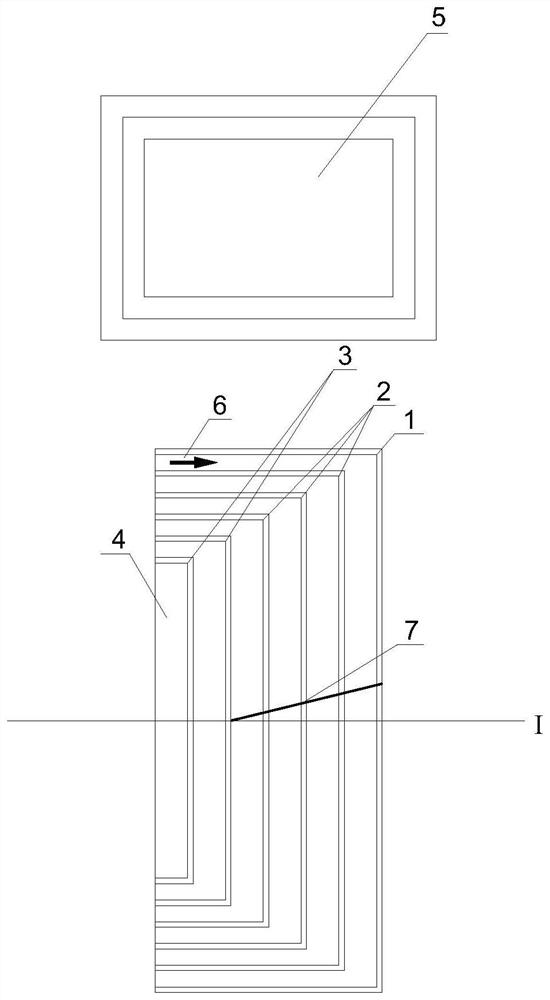

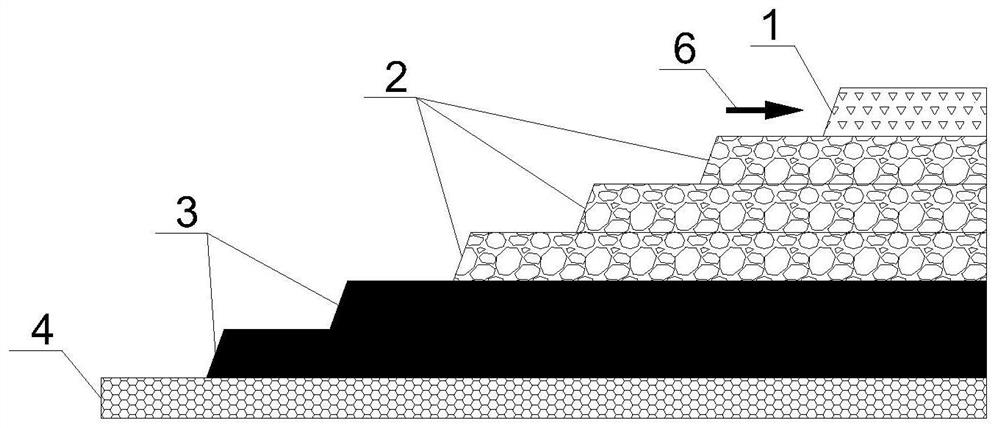

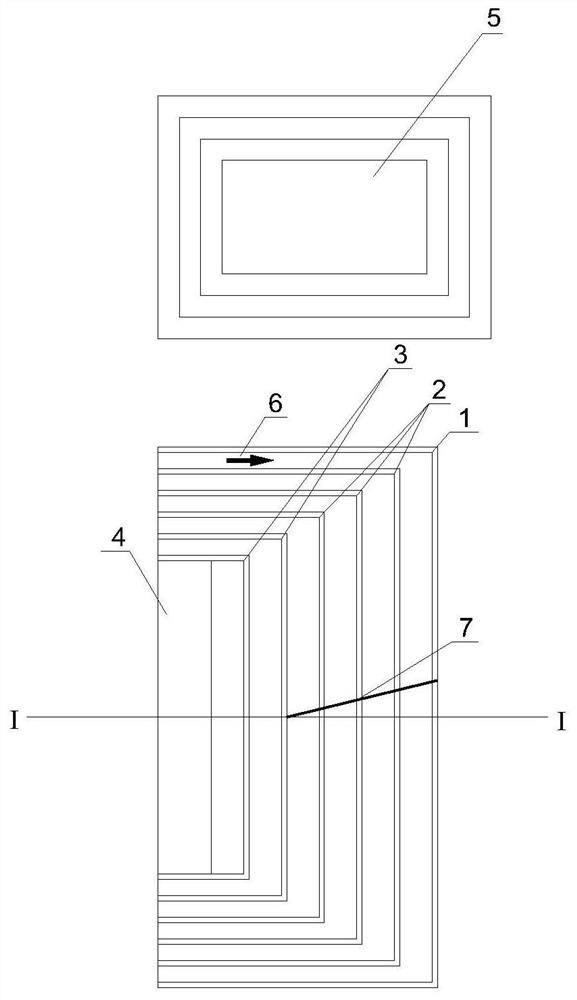

[0029] Such as figure 1 and figure 2 As shown, S1 first digs trenches along the coal seam at the outcrop position of the near-horizontal open-pit coal mine. During the trenching process, a topsoil step 1 and a rock step 2 are formed sequentially from the outside to the inside, and the exposed coal seam is mined. A coal mining step 3 is built in the coal seam, and the coal mining step 3 is formed after the coal seam is exposed. The slope angle of the coal mining step 3 is 70°. During the formation of the coal mining step 3, coal is mined and transported to the ground production system; the entire excavation The topsoil and rock stripped off du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com