Across critical carbon dioxide automobile air conditioner system mechanical conditioning type expansion valve

An automobile air-conditioning system, carbon dioxide technology, applied in refrigerators, refrigeration and liquefaction, fluid circulation arrangements, etc., can solve the problems of adjustment range limitation, system oscillation, and affecting the stability of refrigeration system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

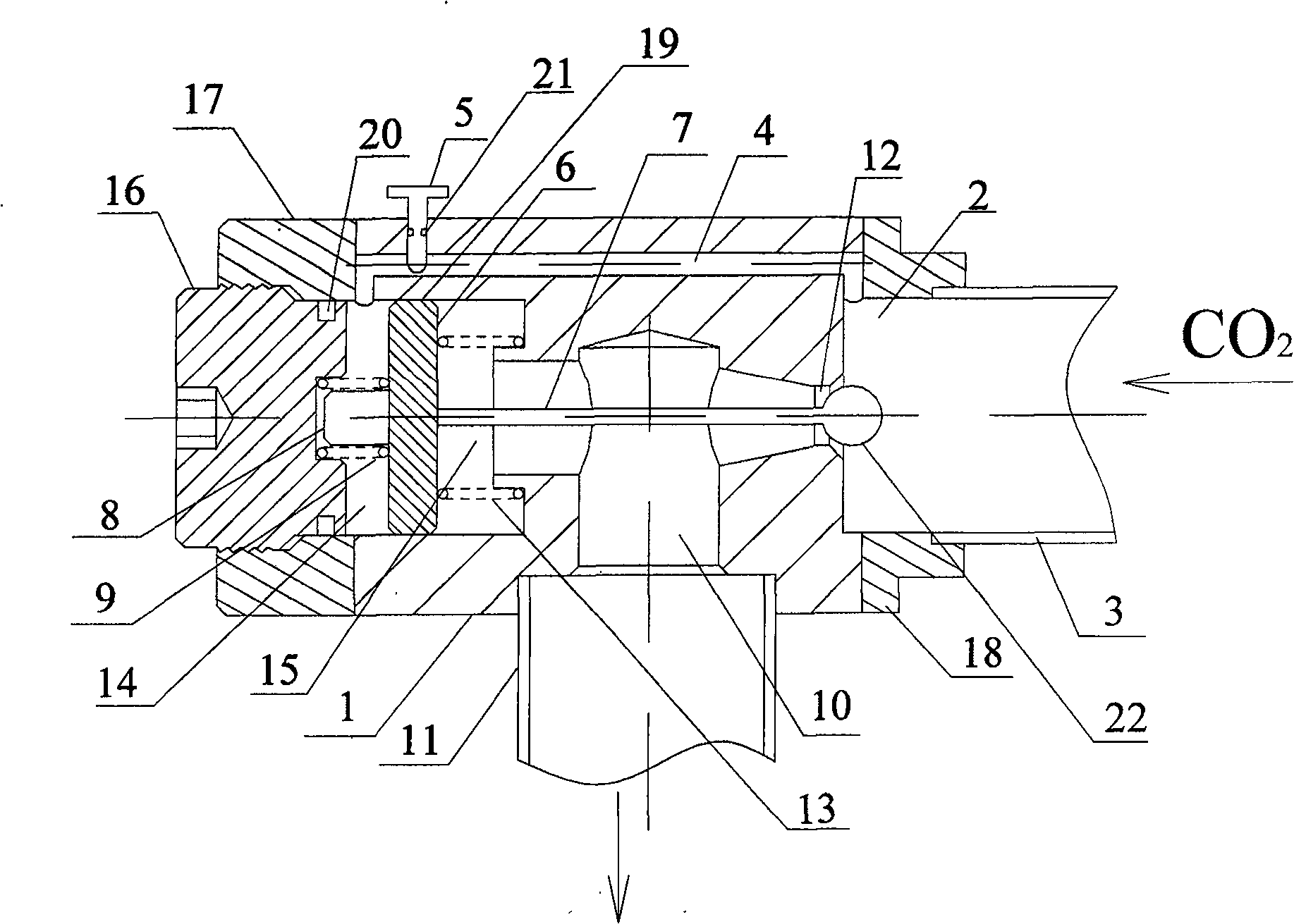

[0014] Such as figure 1 As shown, the present invention includes: valve body 1, air inlet 2, high-pressure chamber air intake passage 4, high-pressure chamber air intake adjustment bolt 5, piston 6, valve stem 7, valve opening spring 9, air outlet 10, valve closing spring 13. High pressure chamber 14, low pressure chamber 15, preload adjusting bolt 16, cylinder 19, spherical valve head 22. The left end of the valve body 1 is provided with a cylinder 19, the right end of the valve body 1 is fixed with an air inlet pipe joint 18 with an air inlet pipe 3, the air outlet 10 with the air outlet pipe 11 is placed at the lower part of the valve body 1, and the cylinder sealing nut 17 is fixed on the left end of the valve body 1 , the cylinder seal nut 17 is internally screwed with a pre-tightening adjustment bolt 16, the piston connecting rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com