Telescopic laser land leveler

A laser leveling and telescopic technology, applied in the fields of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of inability to adjust, poor adaptability, etc., and achieve the effect of low structural cost, improved accuracy, and flexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

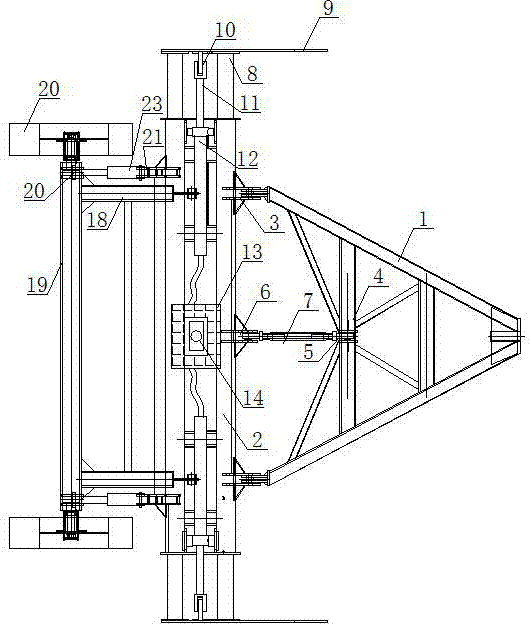

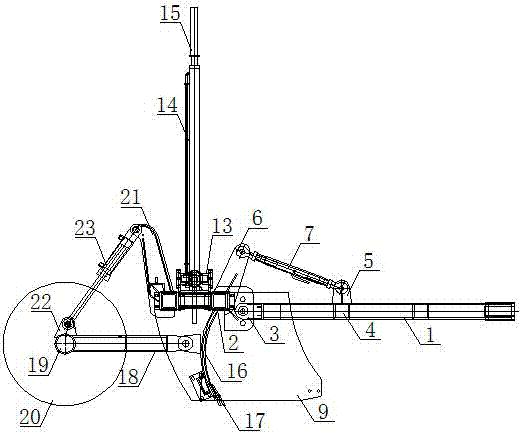

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] as attached figure 1 , 2 As shown, a telescopic laser grader of the present invention includes a frame body 1, a hollow beam 2, a first hinge 3, a reinforcing rod 4, a second hinge 5, a third hinge 6, a connecting rod 7, an insert Plate 8, side plate 9, rotating shaft 10, telescopic rod 11, hydraulic cylinder 12, hydraulic motor 13, laser pole 14, laser device 15, shovel plate 16, shovel blade 17, rear connecting arm 18, axle 19, wheel 20, arc shaped arm 21, base 22 and shock absorber 23, the frame body 1 is movably connected with a hollow beam 2 through the first hinge 3; the middle of the frame body 1 is fixedly equipped with a reinforcement rod 4; The middle part of the hollow beam 2 is respectively provided with a second hinge 5 and a third hinge 6; a connecting rod 7 is arranged between the second hinge 5 and the third h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com