Clay expansion-proof agent for high temperature acidification

An anti-swelling agent and clay technology, applied in the field of chemical agents, can solve the problems of acidification effect and difficulty of residual acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The composition, preparation process and performance parameters of the present invention will be described in detail below in conjunction with examples.

[0025] (1) Raw material performance requirements

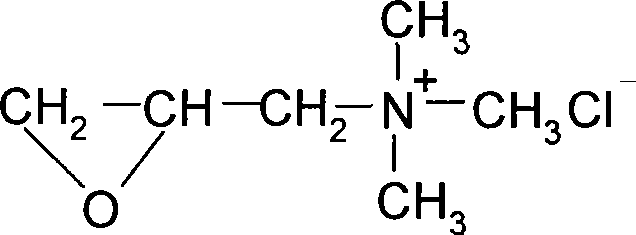

[0026] The effective content of 2,3-glycidyltrimethylammonium chloride is greater than 96%;

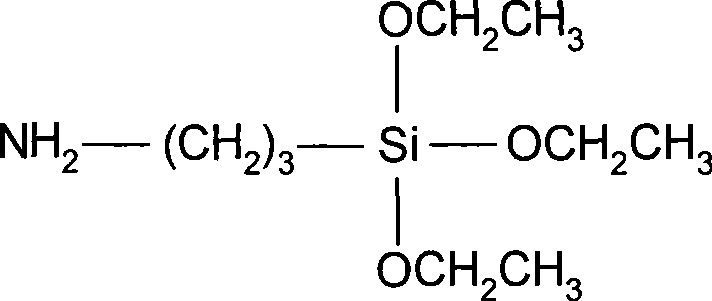

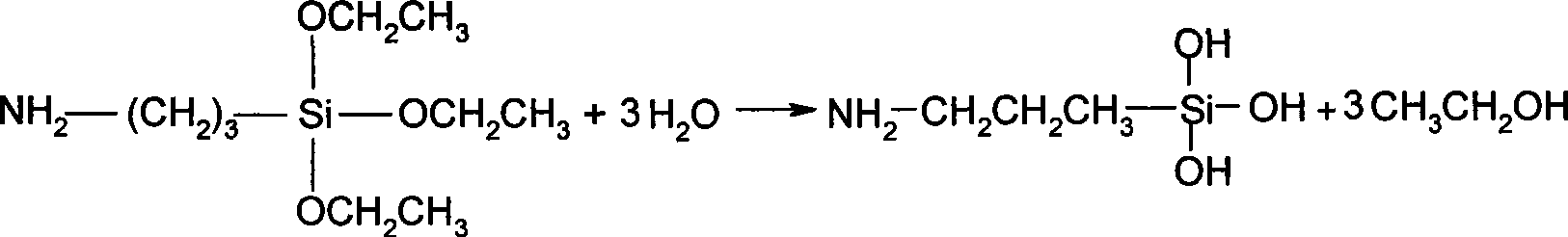

[0027] The effective content of γ-aminopropyl trihydroxysilane is greater than 98%;

[0028] The effective content of guanidine hydrochloride is greater than 93%.

[0029] (2) Preparation examples and performance parameters of clay anti-swelling agent for high temperature acidification

[0030] To the activated 1m 3 Add 650kg of water into the emulsifier, heat to 45°C, stir at low speed, slowly add 15kg of guanidine hydrochloride and 300kg of 2,3-glycidyltrimethylammonium chloride, and stir until completely dissolved. Adjust the mixer to a high speed, add 35kg of γ-aminopropyltrihydroxysilane while stirring, and stir until a uniform transparent solution is formed, which is the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com