A low-permeability oil displacement surfactant and its preparation and product

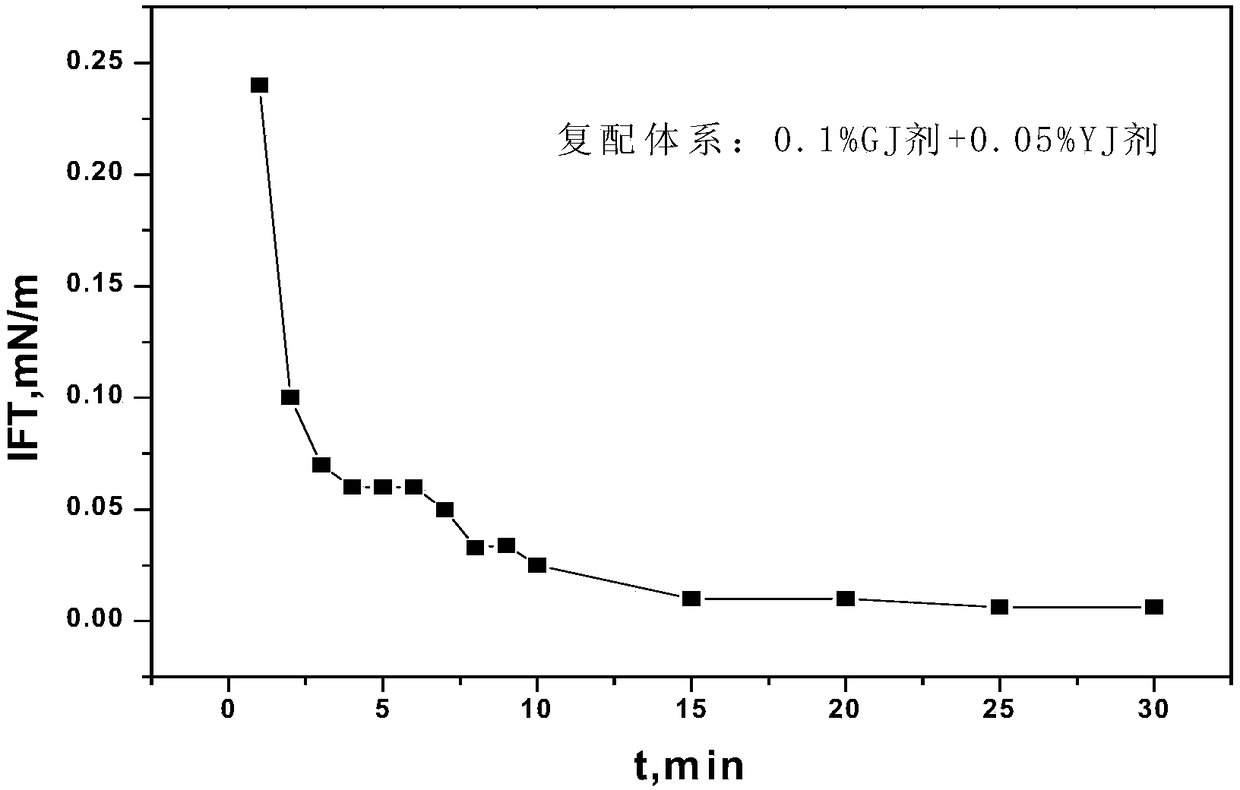

A technology of surfactants and active agents, which is applied in the field of low-permeability reservoir flooding surfactants and its preparation and products, can solve the problems of low water injection production efficiency, prominent water locking effect, and small pore throat radius in reservoirs. Achieve excellent interfacial tension and oil washing ability, increase the capillary number of displacement fluid, and reduce the effect of oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Weigh 0.4mol alkanolamide and place it in a flask, add an appropriate amount of methanol solvent, then add 0.05mol sodium hydroxide as a basic catalyst, weigh 0.2mol allyl glycidyl ether, slowly add it dropwise and stir, after the dropwise addition is completed , raise the temperature to 30°C for 1h, then reflux for 8h; then add sulfuric acid to the reaction system to adjust the pH to 3-5, heat to 80°C for 1h, after the hydrolysis is complete, add sodium hydroxide to the reaction system to adjust When the pH is neutral, add 0.2mol sodium acetate, continue heating and stirring at 30°C under alkaline conditions, and react for 3 hours. After the reaction, wash with absolute ethanol, filter, and distill under reduced pressure to obtain GJ-1 agent.

Embodiment 2

[0078] Weigh 0.5 mol alkanolamide and place it in a flask, add an appropriate amount of ethanol solvent, then add 0.05 mol potassium hydroxide, weigh 0.25 mol ethylene glycol glycidyl ether compound, slowly drop and stir, after the drop is completed, Raise the temperature to 40°C and keep it for 1h, then reflux for 2h; then add hydrochloric acid to the reaction system to adjust the pH to 3-5, heat to 80°C for 2h, after the hydrolysis is completed, add potassium hydroxide to the reaction system to adjust When the pH is neutral, add 0.25mol sodium benzoate, continue heating and stirring at 40°C under alkaline conditions, and react for 9 hours. After the reaction, wash with absolute ethanol, filter, and distill under reduced pressure to obtain GJ-2 agent.

Embodiment 3

[0080] Weigh 0.5mol of polyoxyethylene alkyl acyl alcohol amine and place it in a flask, add an appropriate amount of acetone solvent, then add 0.05mol of sodium carbonate, weigh 0.25mol of phenyl glycidyl ether compounds, slowly drop and stir, drop After completion, raise the temperature to 50°C for 1 hour, then reflux for 7 hours; add acetic acid to the reaction system to adjust the pH to 3-5, heat to 80°C for 3 hours, and then add sodium carbonate to the reaction system after hydrolysis is complete. Adjust the pH to neutral, add 0.25mol sodium chloroacetate, continue heating and stirring at 50°C under alkaline conditions, and react for 4 hours. After the reaction is completed, wash with absolute ethanol, filter, and distill under reduced pressure to obtain GJ-3 agent .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com