High temperature resistance solid free low damage well killing fluid and preparation method thereof

A killing fluid and solid-free technology, applied in the field of killing fluid, can solve the problems of large dosage, single performance, weak brine thickening ability, etc., and achieve the effect of convenient preparation, simple formula and low corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

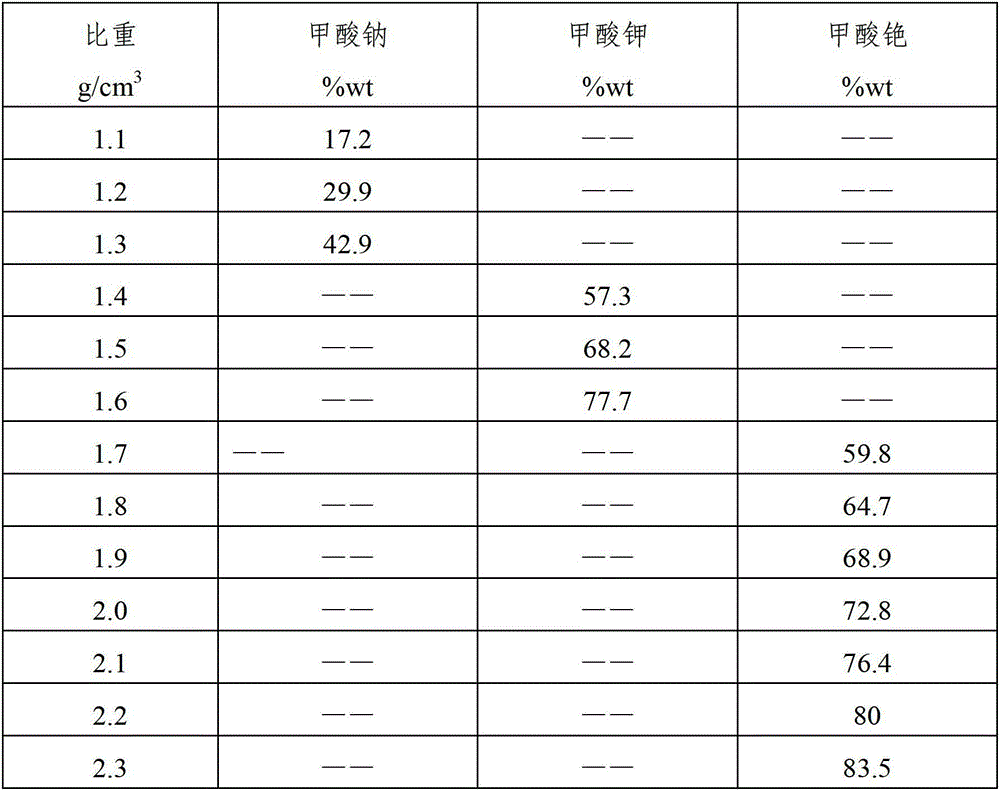

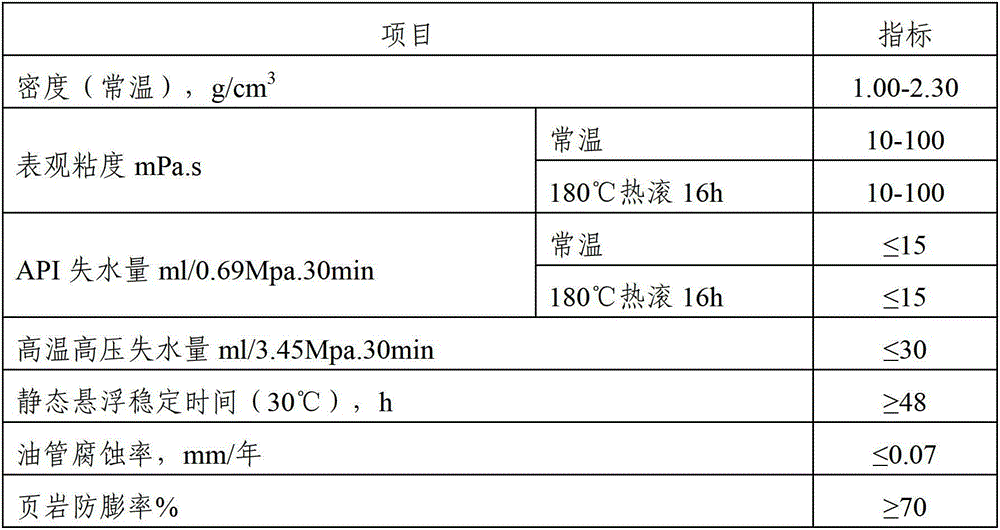

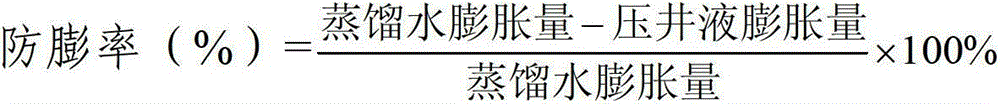

Method used

Image

Examples

Embodiment 21m3

[0092] Example 2 with 1m 3 , the specific gravity is 1.6g / cm 3 For example, prepare according to the well fluid formula.

[0093] formula:

[0094] Potassium sulfomethyl humate 48kg;

[0095] Potassium formate 1232kg;

[0096] A quaternary multifunctional polymer with a molecular weight of 2 million (acrylamide: N,N-dimethylacrylamide: 2-acrylamido-2-methylpropanesulfonic acid: sodium acrylate in a molar ratio of 4:3:70 : 25) 16kg;

[0097] Low-viscosity polyanionic cellulose (purchased from Mingzhu Chemical Co., Ltd.) 24kg;

[0098] NTA and sodium molybdate, sodium citrate ratio are the mixture 2.4kg of 1: 1: 0.5;

[0099] 277.6kg of water.

[0100] The preparation method, detection index and detection method are as in Example 1. The test results are shown in Table 4 and all meet the requirements.

[0101] Table 4 Test results of killing fluid performance indicators

[0102]

[0103]

Embodiment 31m3

[0104] Example 3 with 1m 3 , the specific gravity is 2.1g / cm 3 For example, prepare according to the well fluid formula.

[0105] formula:

[0106] Potassium sulfomethyl humate 16.8kg;

[0107] Cesium formate 1604.4kg;

[0108] The molecular weight is 1 million quaternary multifunctional polymers (the molar ratio of acrylamide: N,N-dimethylacrylamide: 2-acrylamido-2-methylpropanesulfonic acid: sodium acrylate is 67:5:10: 20.5) 10.5kg;

[0109] Low-viscosity polyanionic cellulose (purchased from Mingzhu Chemical Co., Ltd.) 20kg;

[0110] NTA and sodium molybdate, sodium citrate ratio are 1.2kg of the mixture of 1: 1: 0.2;

[0111] 447.1kg of water.

[0112] The preparation method, detection index and detection method are as in Example 1. The test results are shown in Table 5 and all meet the requirements.

[0113] Table 5 Test results of killing fluid performance indicators

[0114]

[0115] In the experimental example, the specific gravity is 2.1g / cm 3 As an exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com