Preparation method of urea modified phosphonium salt tanning agent

A technology of phosphonium salt tanning agent and urea, which is applied in the field of preparation of urea-modified phosphonium salt tanning agent, can solve the problems of high cost and numerous processes, and achieve the effect of improving the stability of heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

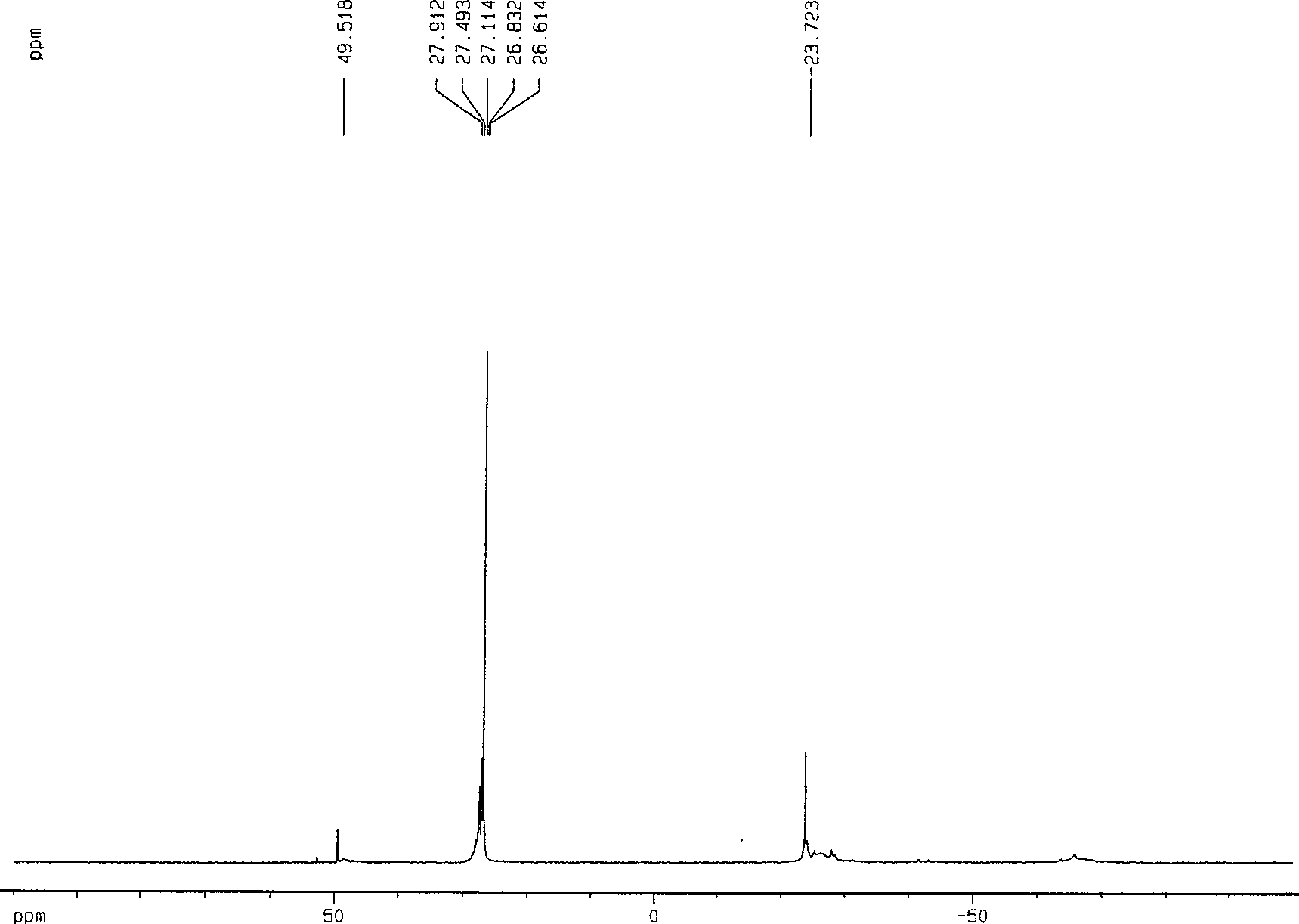

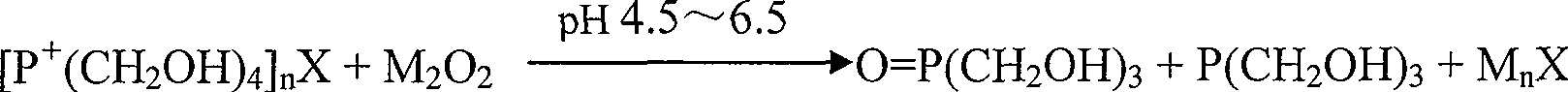

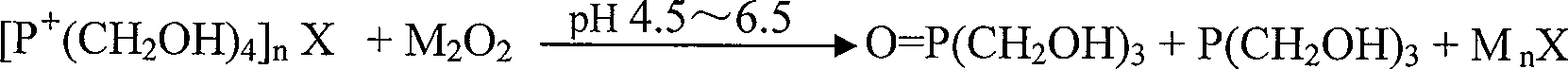

Method used

Image

Examples

Embodiment 1

[0039] Tetrahydroxymethylphosphonium chloride P(CH with a mass concentration of 60% 2 Oh) 4 200Kg of Cl solution is added in a heat-resistant, pressure-resistant and corrosion-resistant reaction kettle equipped with a stirrer and a thermometer. Adjust pH = 6.5 with sodium hydroxide. Raise the temperature to 90°C, slowly add 40Kg of hydrogen peroxide, react for 4.0 hours, cool the initial product, adjust pH=6.5 with sodium hydroxide, and obtain a light yellow solution.

[0040] Add 60Kg of urea and 200Kg of deionized water into another reactor and mix them. Add 15Kg of formaldehyde, raise the temperature to 50°C and react for 3.0 hours, and adjust the pH to 6.0 with sodium bicarbonate. Add the above light yellow solution into the reactor, raise the temperature to 90°C, react for 6.0 hours, cool down to 40°C, slowly add 30Kg of hydrogen peroxide, and react for 2.0 hours to obtain a light yellow viscous liquid chrome-free main tanning agent for leather .

Embodiment 2

[0042] Tetrahydroxymethylphosphonium chloride P(CH with a mass concentration of 90% 2 Oh) 4160Kg of Cl solution is added in a heat-resistant, pressure-resistant and corrosion-resistant reaction kettle equipped with a stirrer and a thermometer. Adjust pH = 4.5 with sodium bicarbonate. Raise the temperature to 70°C, slowly add 25Kg of lithium peroxide, react for 2.0 hours, cool the initial product, and adjust the pH to 6.0 with sodium hydroxide to obtain a light yellow solution.

[0043] Add 30Kg of urea and 150Kg of deionized water into another reactor and mix them. Add 10Kg of acetaldehyde, raise the temperature to 40°C and react for 2.0 hours, and adjust the pH to 5.0 with sodium bicarbonate. Add the above light yellow solution into the reactor, raise the temperature to 60°C, react for 4.0 hours, cool down to 30°C, slowly add 20Kg of lithium peroxide, and react for 1.0 hour to obtain a light yellow viscous liquid chrome-free main tanning agent for leather .

Embodiment 3

[0045] Tetrahydroxymethylphosphonium bromide P(CH with a mass concentration of 75% 2 Oh) 4 180Kg of Br solution is added in a heat-resistant, pressure-resistant and corrosion-resistant reaction kettle equipped with a stirrer and a thermometer. Adjust pH = 5.5 with sodium hydroxide. Raise the temperature to 80°C, slowly add 33Kg of sodium peroxide, react for 3.0 hours, cool the initial product, and adjust the pH to 6.3 with sodium hydroxide to obtain a light yellow solution.

[0046] Add 45Kg of urea and 175Kg of deionized water into another reactor and mix them. Add 13Kg of glyoxal, raise the temperature to 45°C and react for 2.5 hours, and adjust the pH to 5.5 with ammonia water. Add the above light yellow solution into the reactor, raise the temperature to 75°C-80°C, react for 5.0 hours, cool down to 35°C, slowly add 25Kg of sodium peroxide, and react for 1.5 hours to obtain a light yellow viscous liquid leather without chromium Main tanning agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com