Equipment for transporting flexible pipe

A transfer device, tube technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

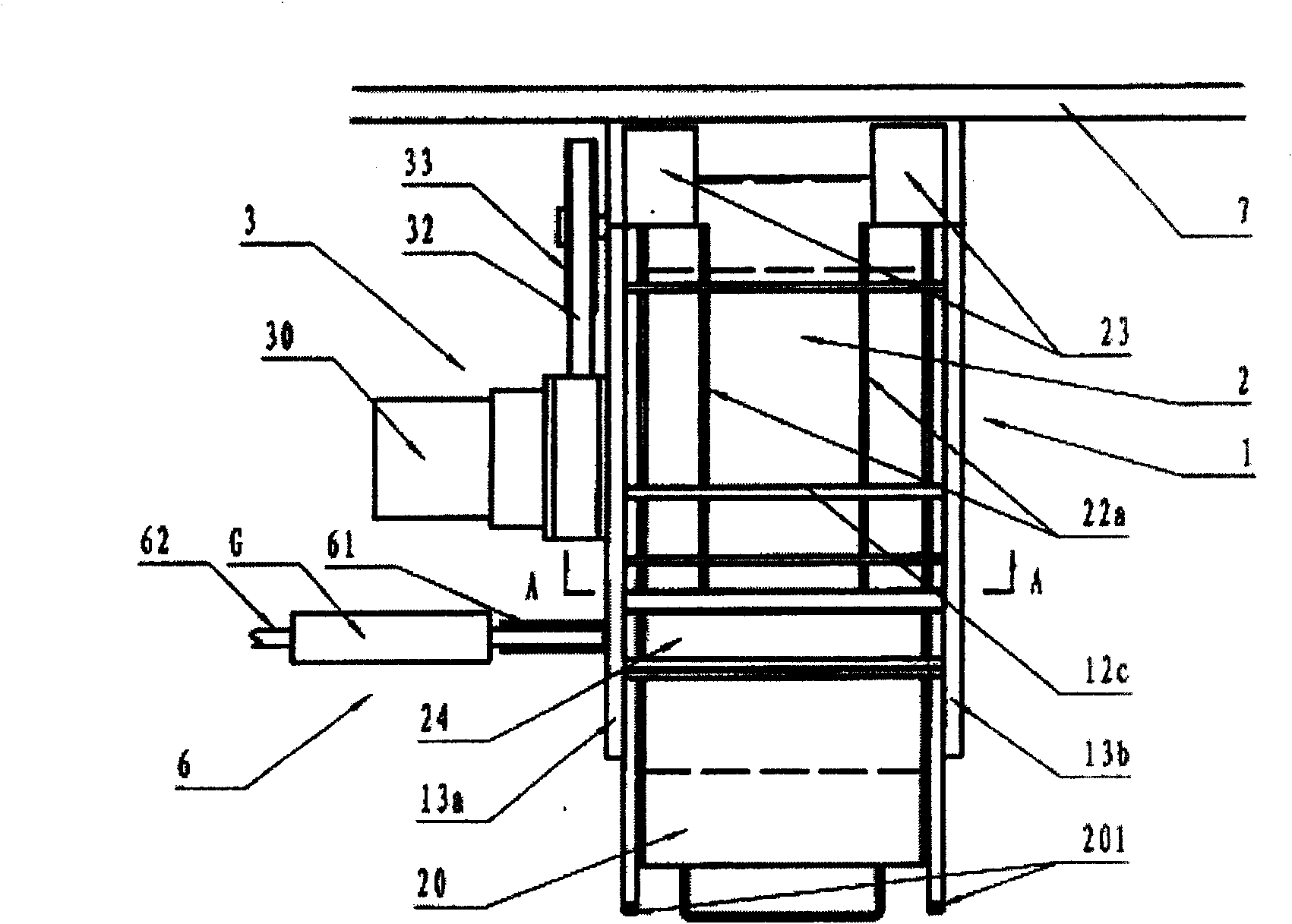

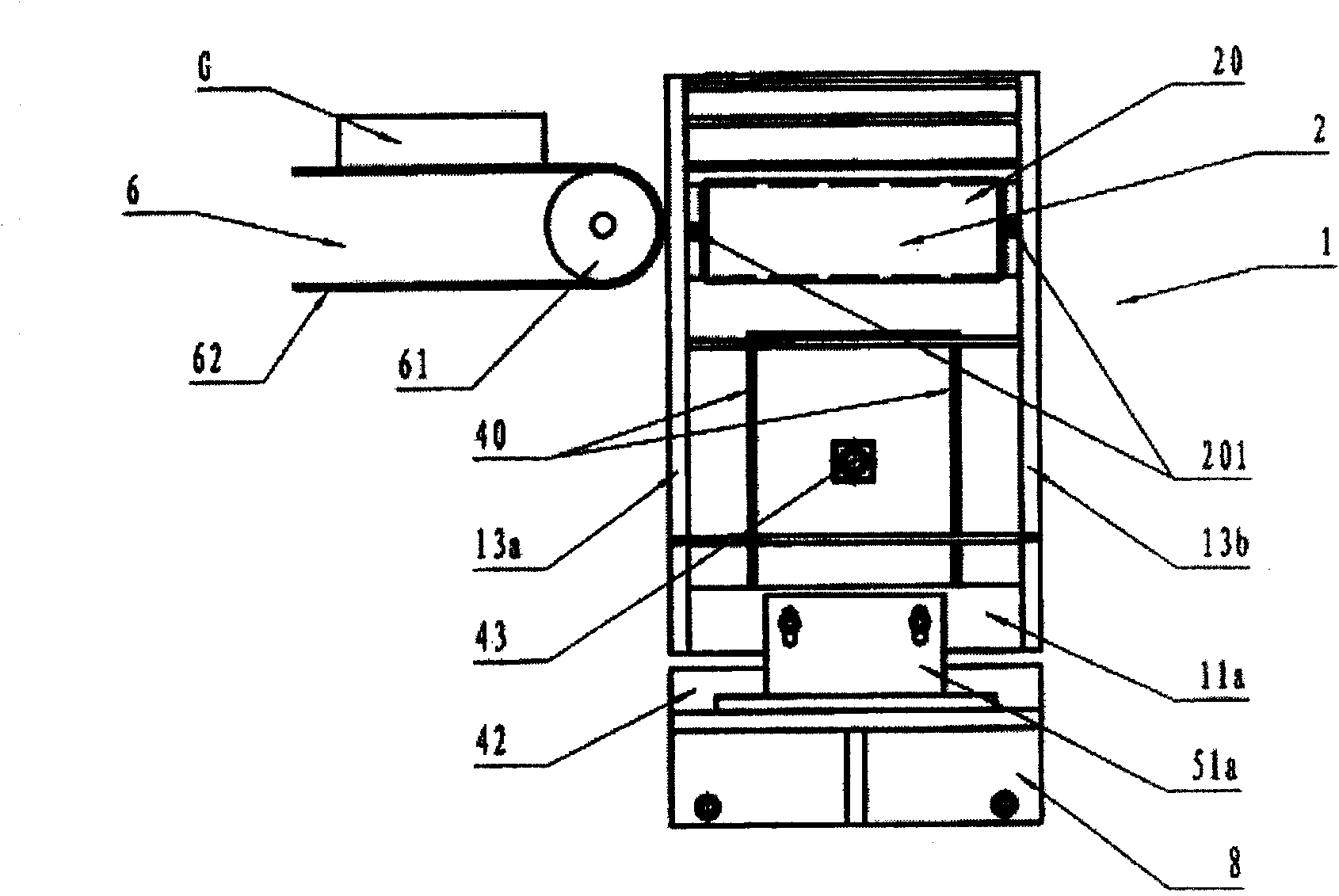

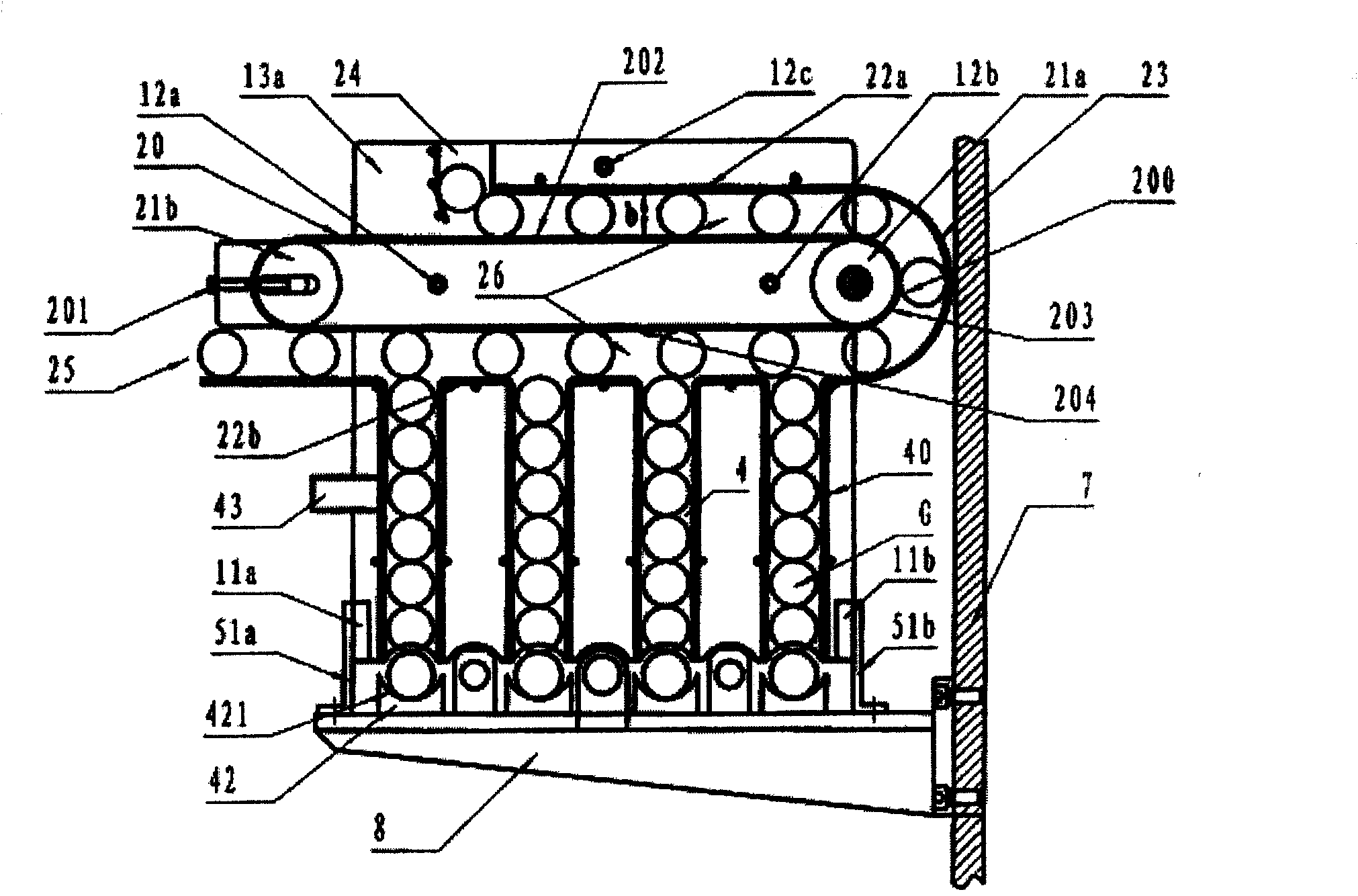

[0024] Such as Figure 1-4 As shown, a hose tube tube transfer device is installed through the main bracket 8 fixed on the equipment installation base plate 7, and it includes a tube tube driven by a drive mechanism 3 that can change the tube tube tube delivery direction. The transfer transmission mechanism 2, the tube tube transfer transmission mechanism is responsible for receiving the hose tubes sent from the tube linear transmission mechanism 6 for radial transport, wherein,

[0025] The tube transfer transmission mechanism 2 is radially arranged relative to the tube linear transmission mechanism 6 arranged in the axial direction, and is installed in the housing 1; The conveyor belt is a radial conveyor belt 20 driven by the driven shaft roller 21b, and the radial conveyor belt 20 is responsible for the radial conveyance of the hose tube;

[0026] The radial conveyor belt is set by the radial conveyor belt driving shaft roller and the radial conveyor belt passive shaft ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com