Assembled square-barrel multi-layer concrete underground garage and manufacturing method thereof

An underground garage and concrete technology, which is applied to underwater structures, buildings for parking cars, water conservancy projects, etc., can solve the problems of low cost, large garage area, and complicated construction, and achieve low cost and strong building structure Large, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

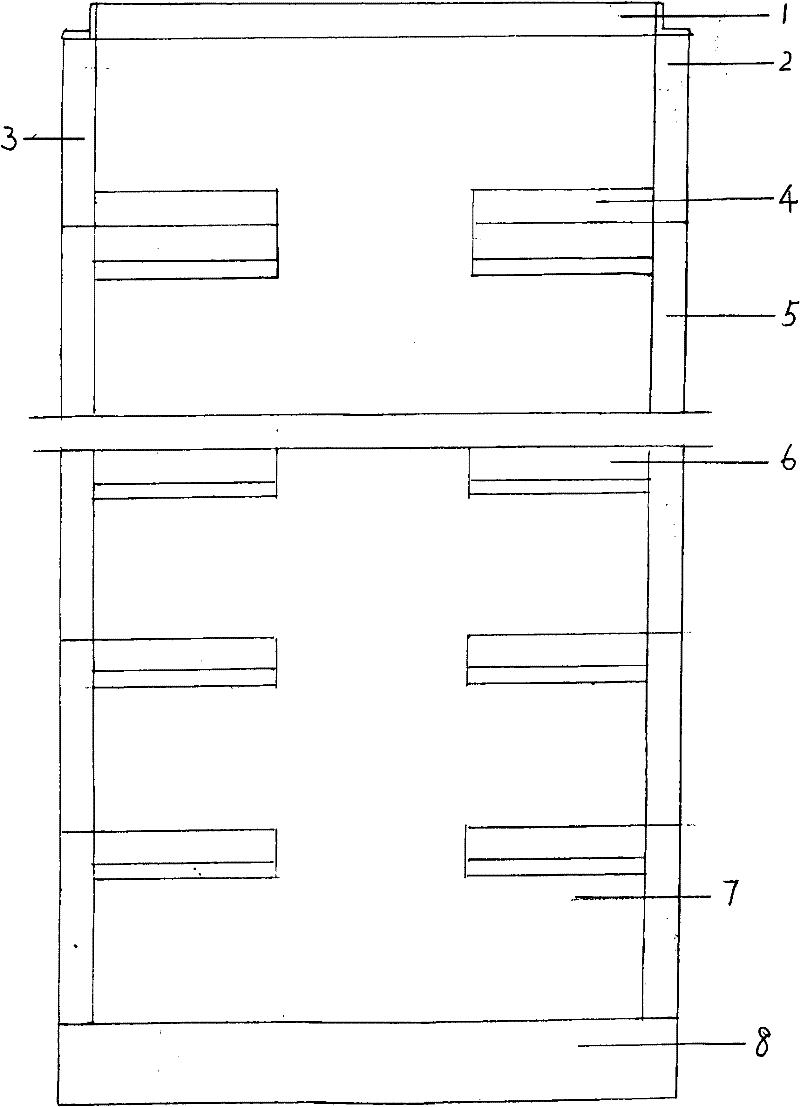

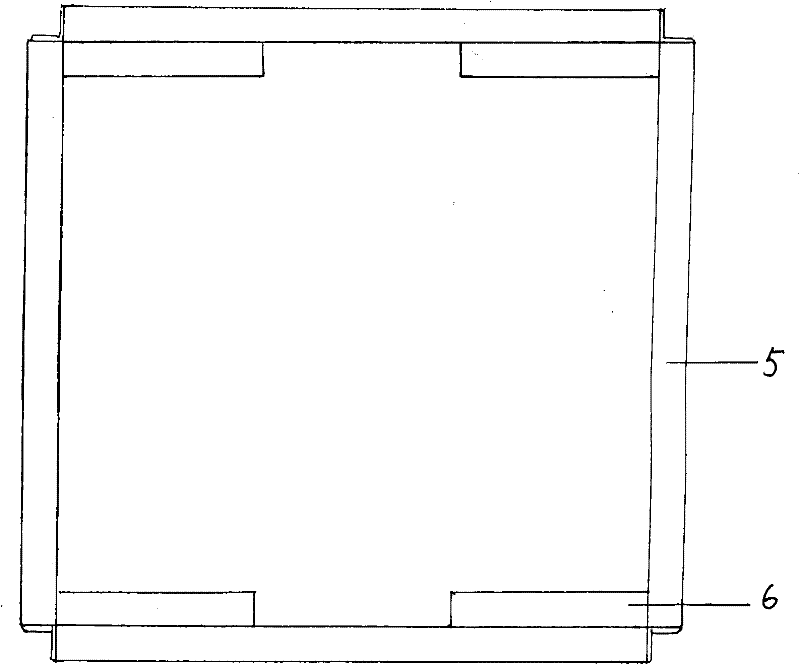

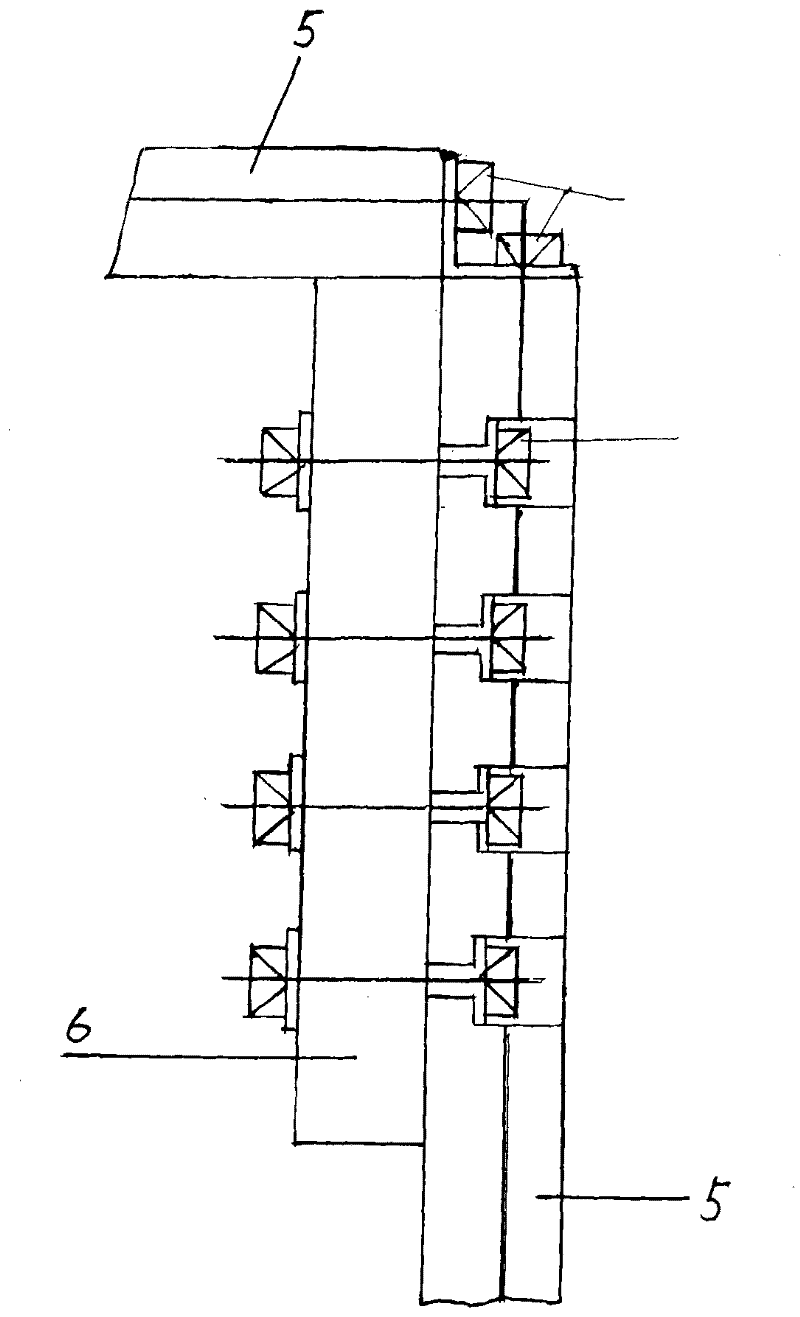

[0057]Including the concrete foundation 8, the equipment room 7 made of four pieces of reinforced concrete prefabricated components with unbonded prestressed tendons connected to each other is fixedly connected to the top of the concrete foundation, and the square tube wall 5 is fastened to the upper part of the equipment room by butt joints Together, the square tube wall is assembled and fastened together by 4 prefabricated component exterior wall panels 501 containing horizontal, vertical and vertical unbonded prestressed tendons, and each layer is butted and fastened together. The reinforced concrete prefabricated component parking beam 6 with unbonded prestressed tendons inside is penetrated and fixed with the corresponding reserved holes of the square tube wall on each floor, and the reinforced concrete prefabricated component with unbonded prestressed tendons inside the transfer floor platform 4 is connected to the The corner of the square tube wall on the ground is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com