A bucket inner wall cleaning machine

A technology for inner wall cleaning and cleaning fluid, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of slow production speed, increased labor costs, high maintenance costs, etc., and achieve low manufacturing costs and operating costs , Improve economic and social benefits, and save social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

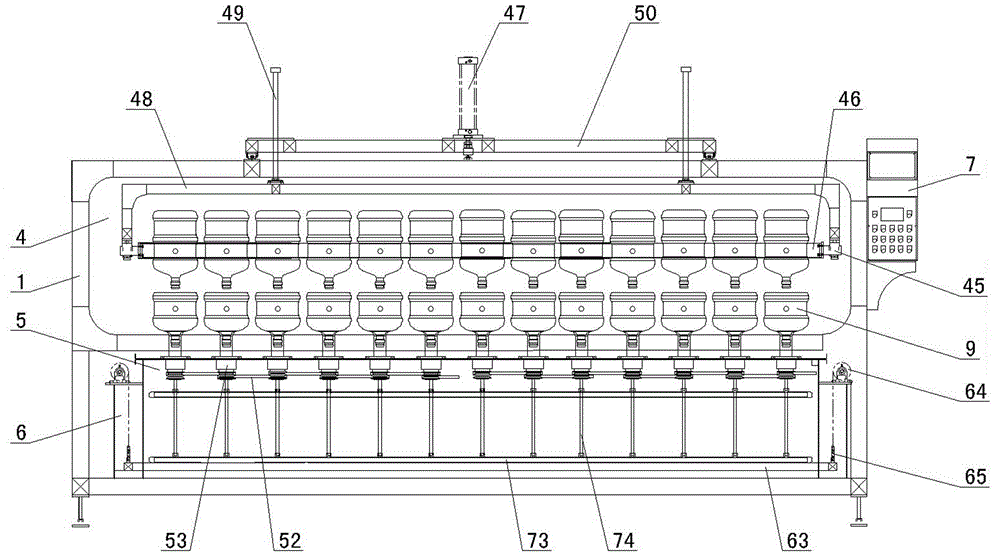

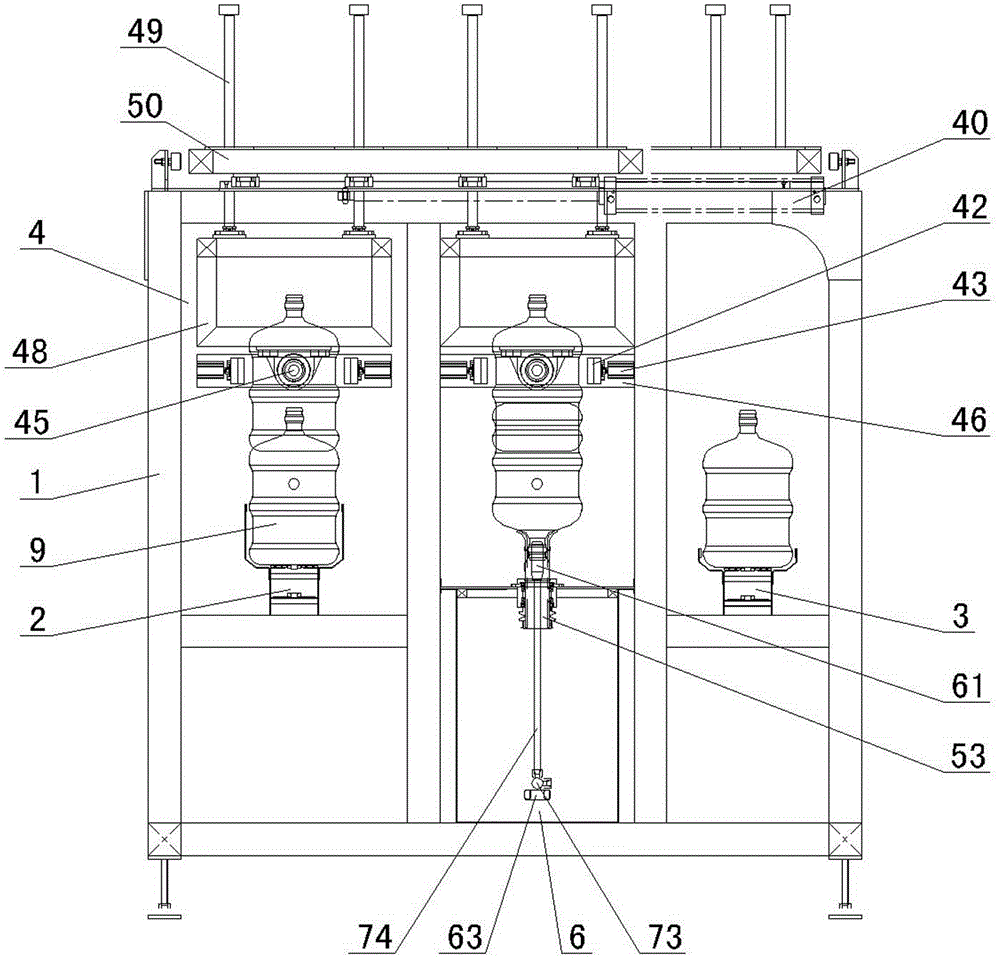

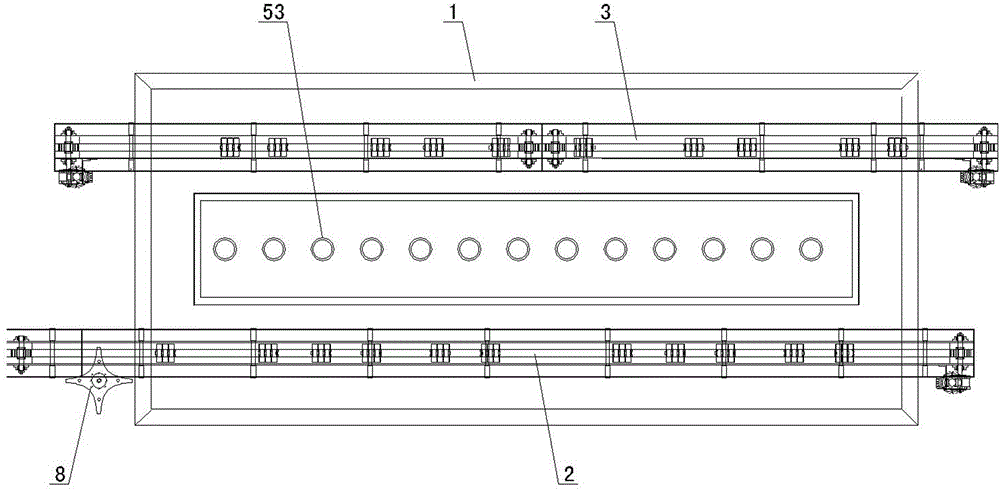

[0024] Such as Figure 1-Figure 6 As shown, the barrel inner wall cleaning machine of the present invention includes a frame 1, a barrel-in conveyor chain 2, a barrel-out conveyor chain 3, a barrel clamping device 4, a barrel-fixing rotating device 5, a high-pressure cleaning device 6 and an operation control box 7 , wherein the high-pressure cleaning device 6 includes a cleaning liquid supply device, a spray head 61 connected to the cleaning liquid supply device through an infusion tube, and a pneumatic vertical lifting mechanism installed on the frame 1 for driving the spray head 61 to vertically lift up and down. The spray head 61 is provided with at least three nozzles 611 which respectively form different angles with the horizontal plane, and the spray head 61 realizes the isobaric cutting of the inner wall of the barrel by rotating 360 degrees up and down under the joint action of the pneumatic vertical lifting mechanism and the solid barrel rotating device 5 cleaning. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com