Family fitment engineering circuit improvement single-tube single-wire system construction material and method

An engineering circuit and single-wire system technology, which is applied in the installation of international patent classification H02G "cable or wire, single-tube single-wire electrical pipeline connectors and construction fields, can solve wall load-bearing and structural safety hazards, steel bar cutting, construction Electrical safety and fire safety do not allow issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

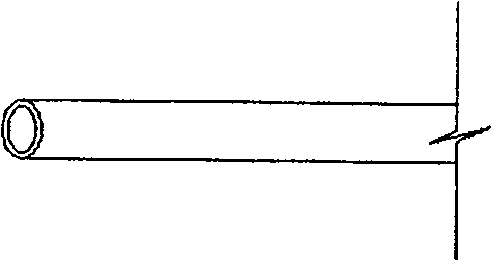

[0099] Such as figure 1 As shown, it is a galvanized wire pipe with an outer diameter of 10mm invented;

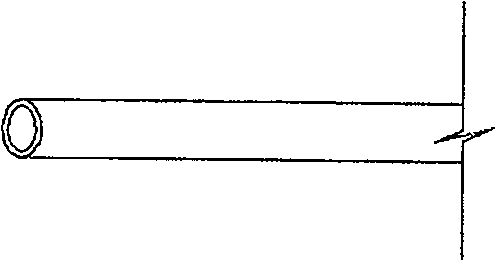

[0100] Such as figure 2 As shown, it is a PVC line pipe with an outer diameter of 10mm and an inner diameter of 8mm. In this PVC plastic flame-retardant wire tube, use color for identification: red tube means phase line, yellow tube means ground wire, blue tube means zero line, white tube means lighting circuit line, and the inside of the tube is Wires and tubes are the same color.

[0101] Subsequent figures show the junction box, lock, elbow, direct connector, and fixing card that match the above-mentioned newly designed wire conduit.

[0102] Such as image 3 As shown, the matching galvanized wire pipe straight head has an outer diameter of 12mm, an inner diameter of 8mm, and a length of 35mm.

[0103] Such as Figure 4 As shown, the matching PVC pipe straight head has an outer diameter of 12mm, an inner diameter of 8mm, and a length of 25mm.

[0104] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com