Multi-pit car type second conveyor

A transporter and mine car technology, applied in mine cars, transport buses, underground transportation, etc., to reduce excavation costs, ensure transport capacity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

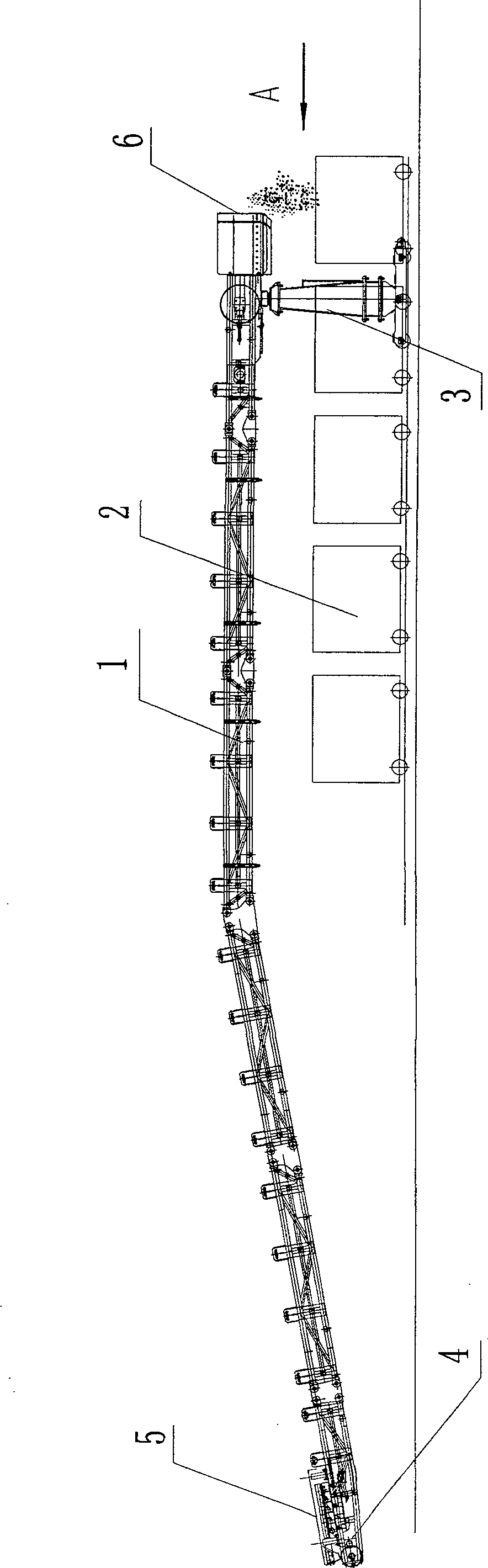

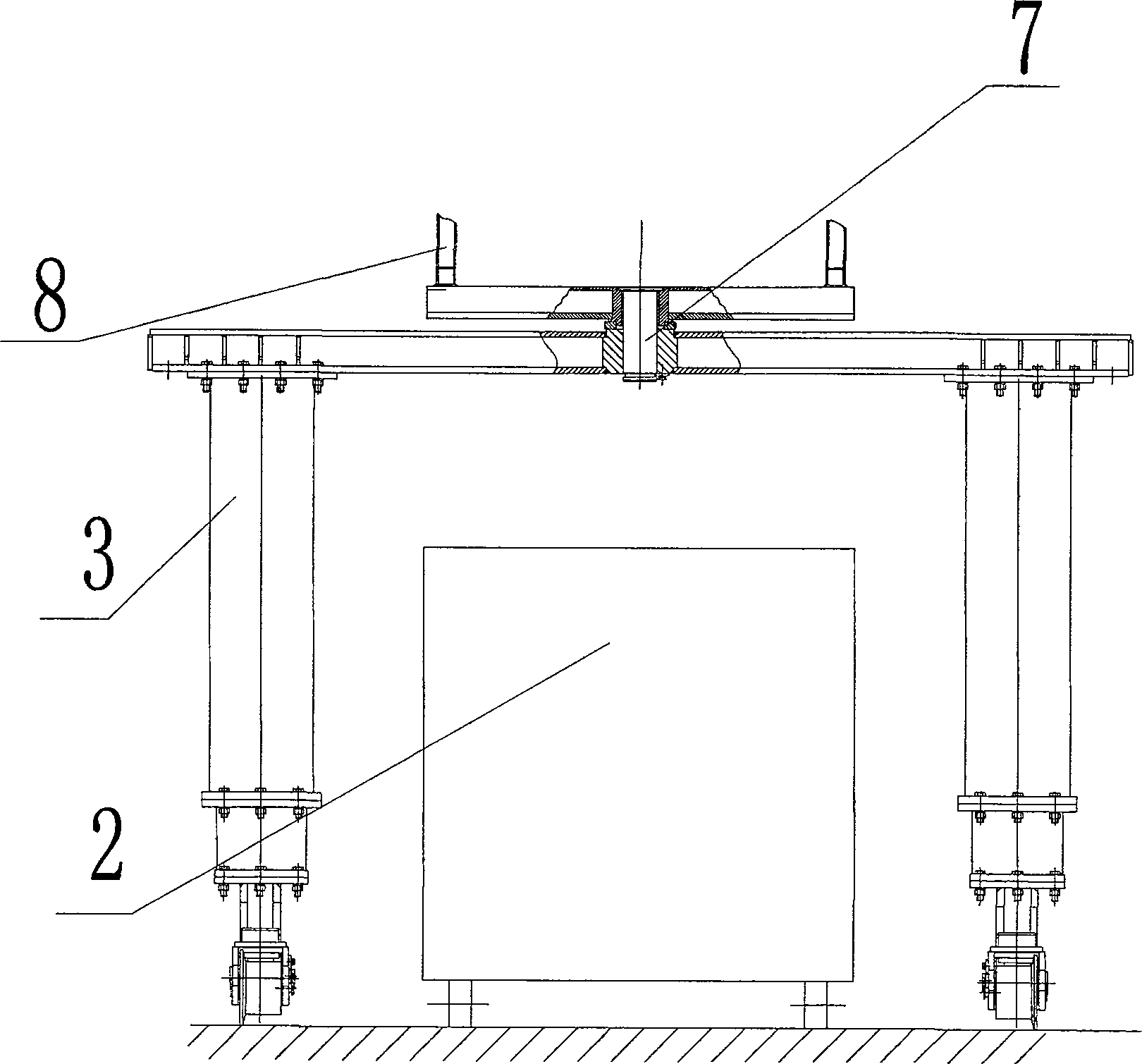

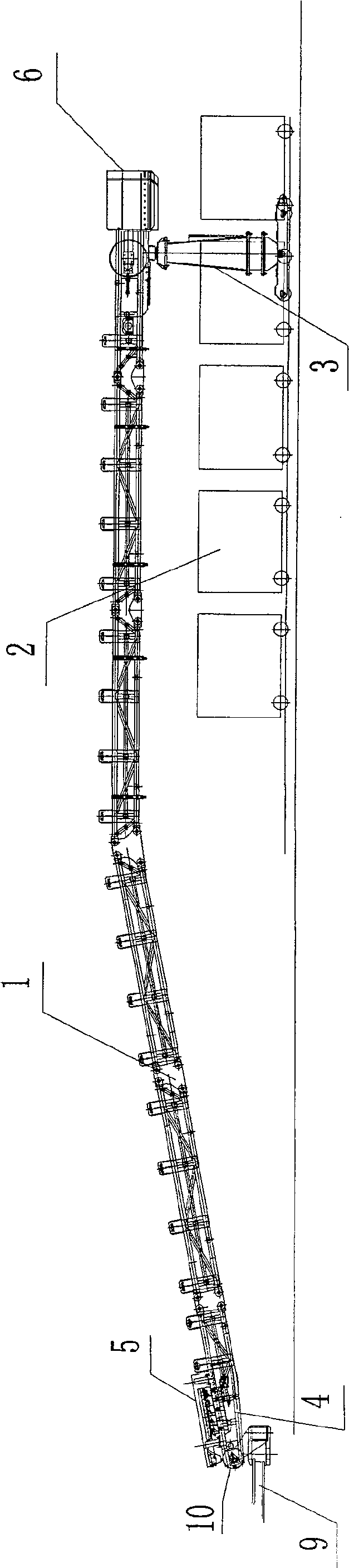

[0019] Such as Figure 1-2 As shown, the multi-mine car type second conveyor of the present invention mainly includes a second conveyor 1, a mine car 2, a gantry trolley 3, a tail frame 4, a material receiving port 5, a discharge port 6, etc.; The tailstock 4 is hinged with the second conveyor turntable 9 supported by the roadheader through the pin shaft 17, and the second conveyor turntable 9 can drive the second conveyor 1 to swing ±12° horizontally; the front machine at the other end of the second conveyor 1 Frame 8 is hinged with gantry trolley 3 through pin II 10 ( figure 2 ), the top of the front frame 8 is a material channel, the middle of the gantry car 3 has a channel for the mine car 2 to pass through, and the gantry car 3 can drive the second conveyor 1 to rotate vertically ± 15°; the receiving port 5 and the discharging port 6 are respectively It is arranged at the front end and the rear end of the second conveyor 1, and the material receiving port 5 arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com