Humidity regulating equipment

A technology of humidity regulation and equipment, applied in the direction of humidity control, control/regulation system, food testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

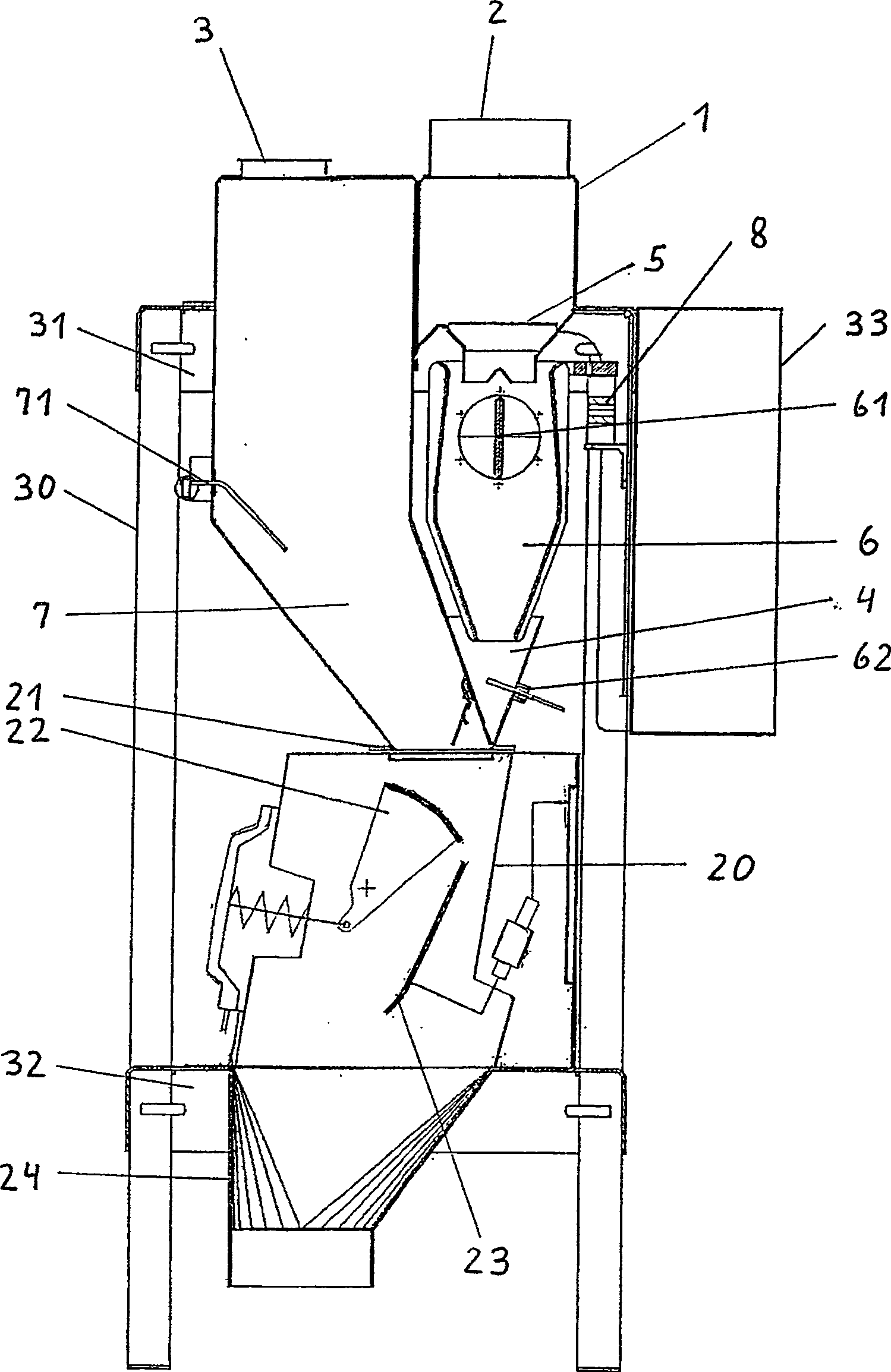

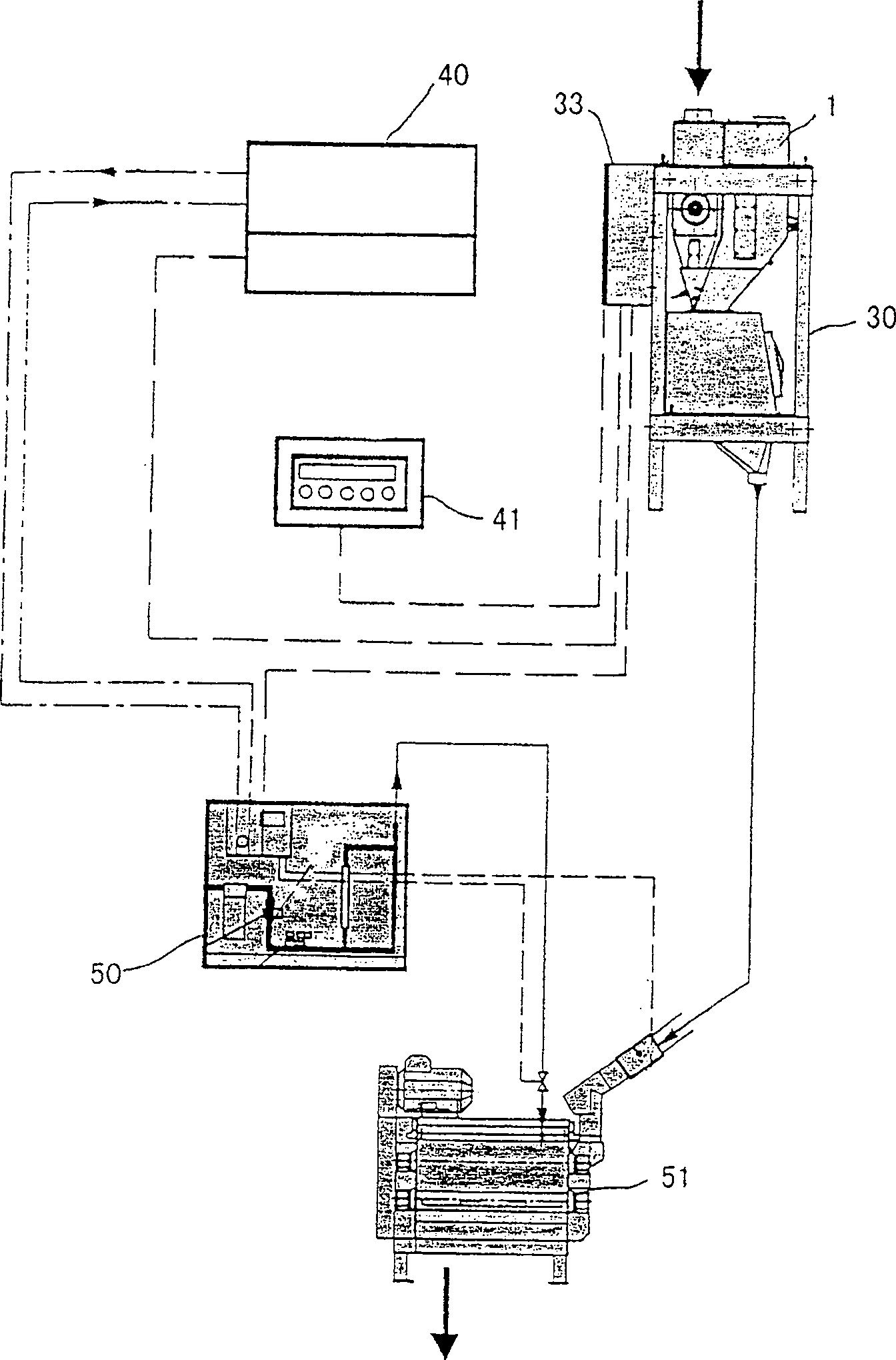

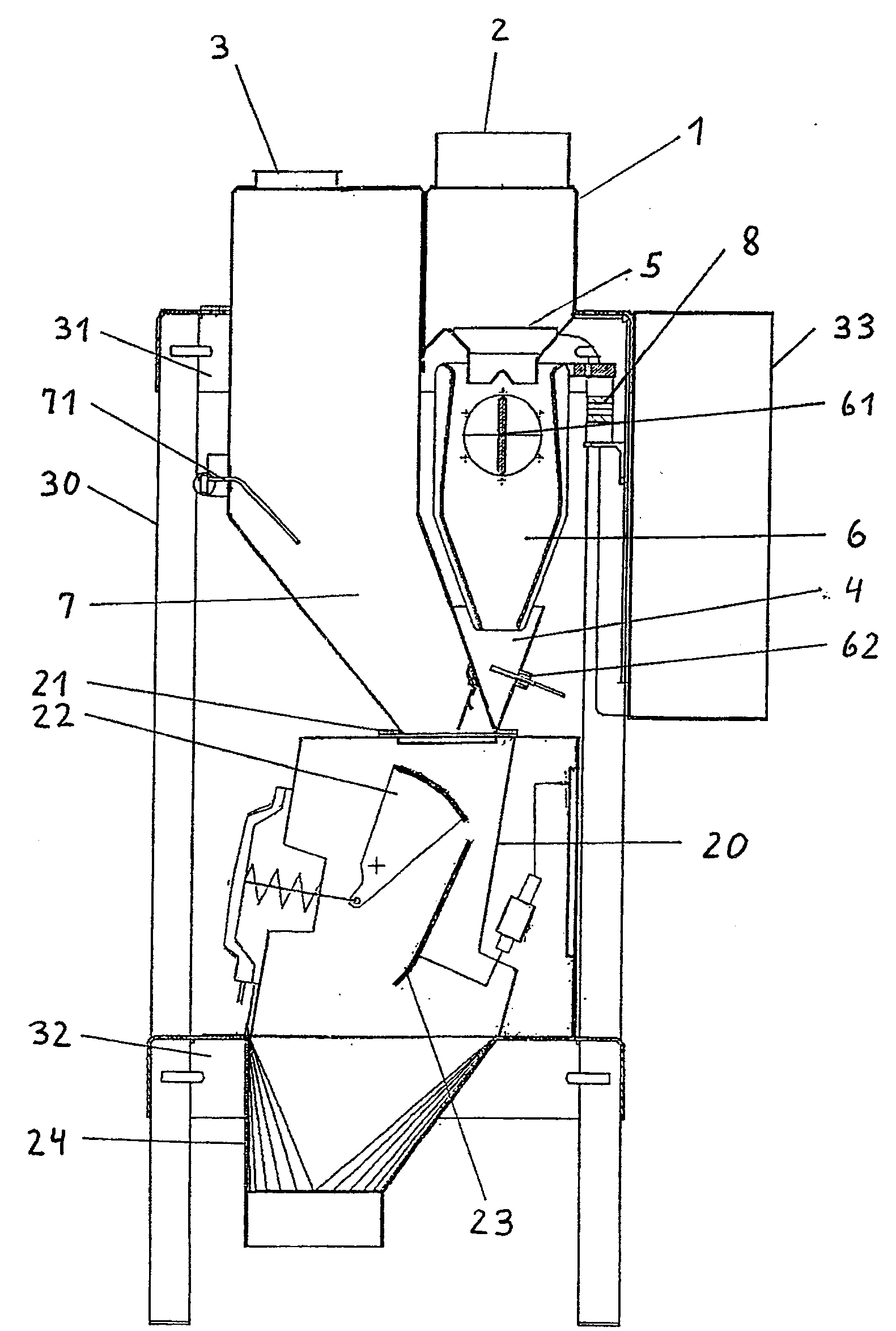

[0015] The humidistat comprises a housing 1 with an inlet 2 , a suction opening 3 and a discharge funnel 4 . Downstream from the inlet 2 are the feed tank 5 , the measuring path 6 and the main passage 7 in this order. The bulk material flow (grain) is damped and homogenized in the conveying device.

[0016] A microwave sensor 61 of the type described in patent document WO 96 / 38721 is arranged in the measuring path 6 , next to the measuring path 6 there is arranged a discharge funnel in which a temperature sensor 62 is arranged.

[0017] A material level sensor 71 is arranged in the main passage 7 for adjusting the material level of the bulk material flow introduced in the patent document EP-B-991473. The material level sensor 71 has a hinged mounting rod, which is set transversely or perpendicular to the flow direction of the bulk material and connected with a signal sensor.

[0018] The discharge funnel 4 is located above the supply port 21 of the flow regulator 20 . With ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com