Suspending chopper box of magnetic suspension train

A technology for maglev trains and chopper boxes, applied in cooling/ventilation/heating transformation, output power conversion devices, electrical components, etc., can solve problems such as poor heat dissipation, many device connections, and difficult installation and maintenance. Achieve the effects of reducing electromagnetic interference, reliable connection, and reducing maintenance costs and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

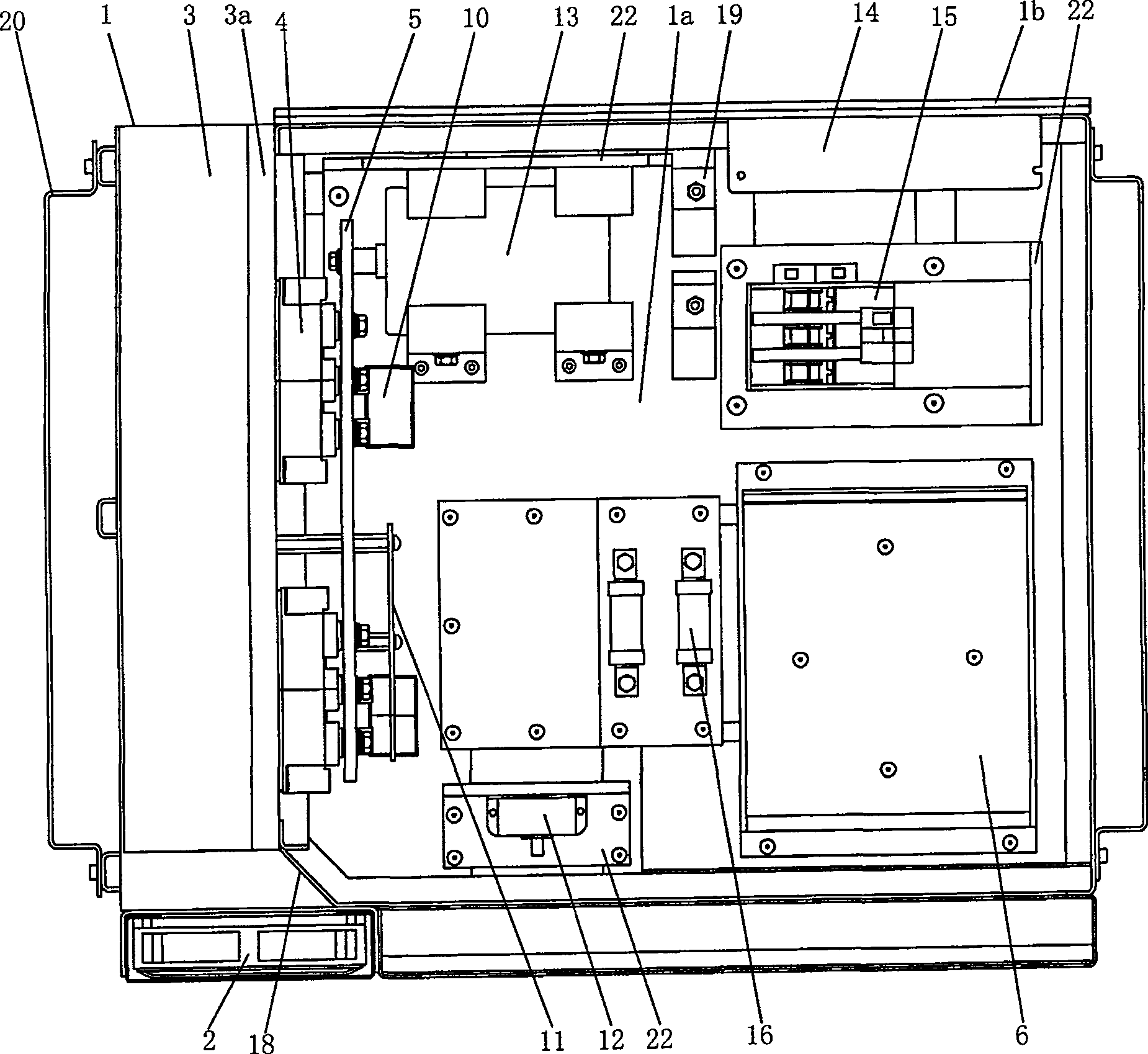

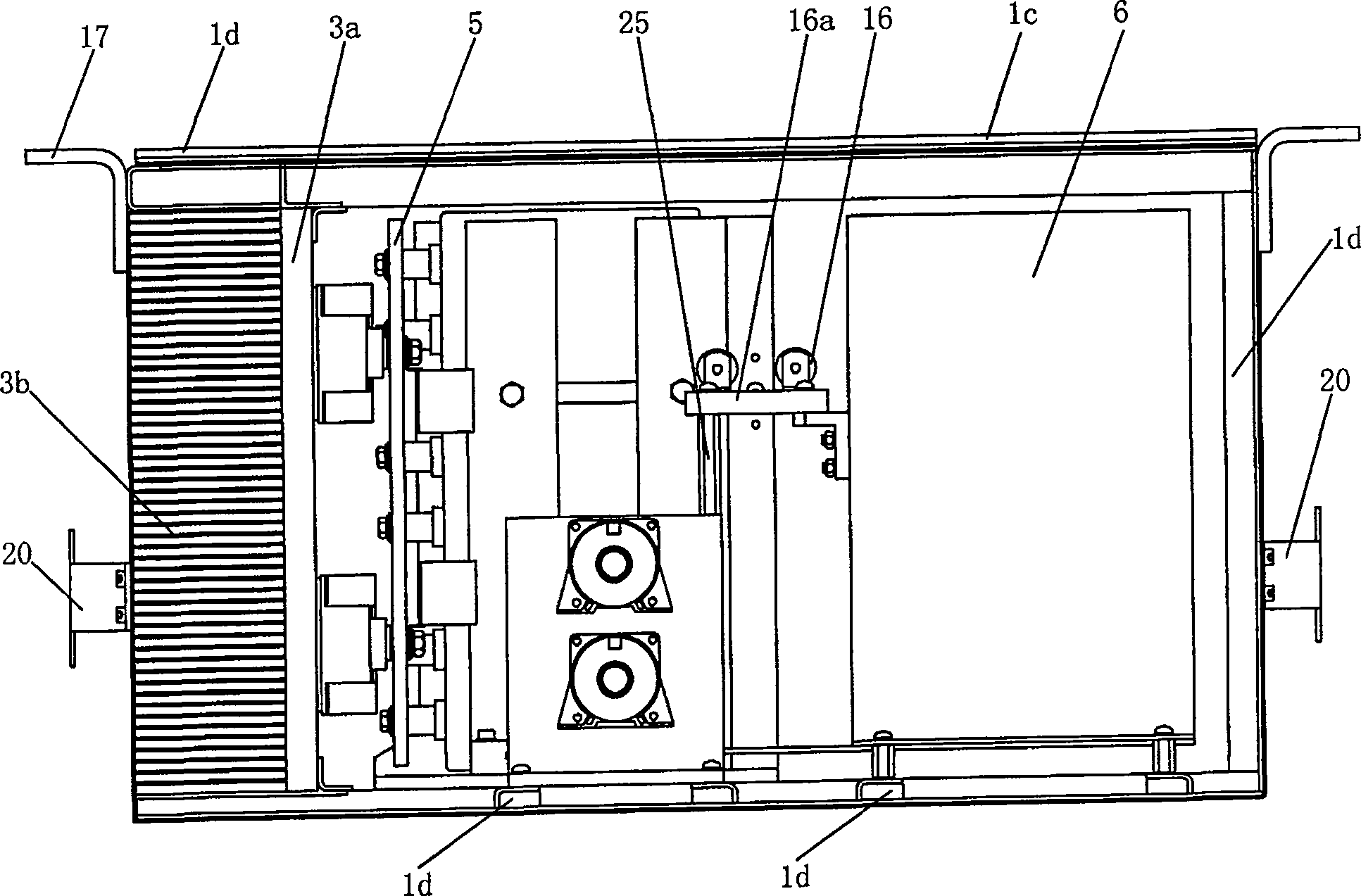

[0038] figure 1 , 3It is shown that a specific embodiment of the present invention is: a levitation chopper box for a maglev train, including a box body 1 , a fan 2 , a radiator 3 , and a power device 4 . The radiator 3 is fixedly installed on the left side of the box body 1, the base of the power device 4 is installed on the radiator 3, and the power end of the power device 4 is fixed on the left side of the upright stacked power busbar 5; Components are distributed in the space on the right side of the laminated power busbar 5, and the internal control box 6 is installed on the far right side of the front part of the bottom plate 1a.

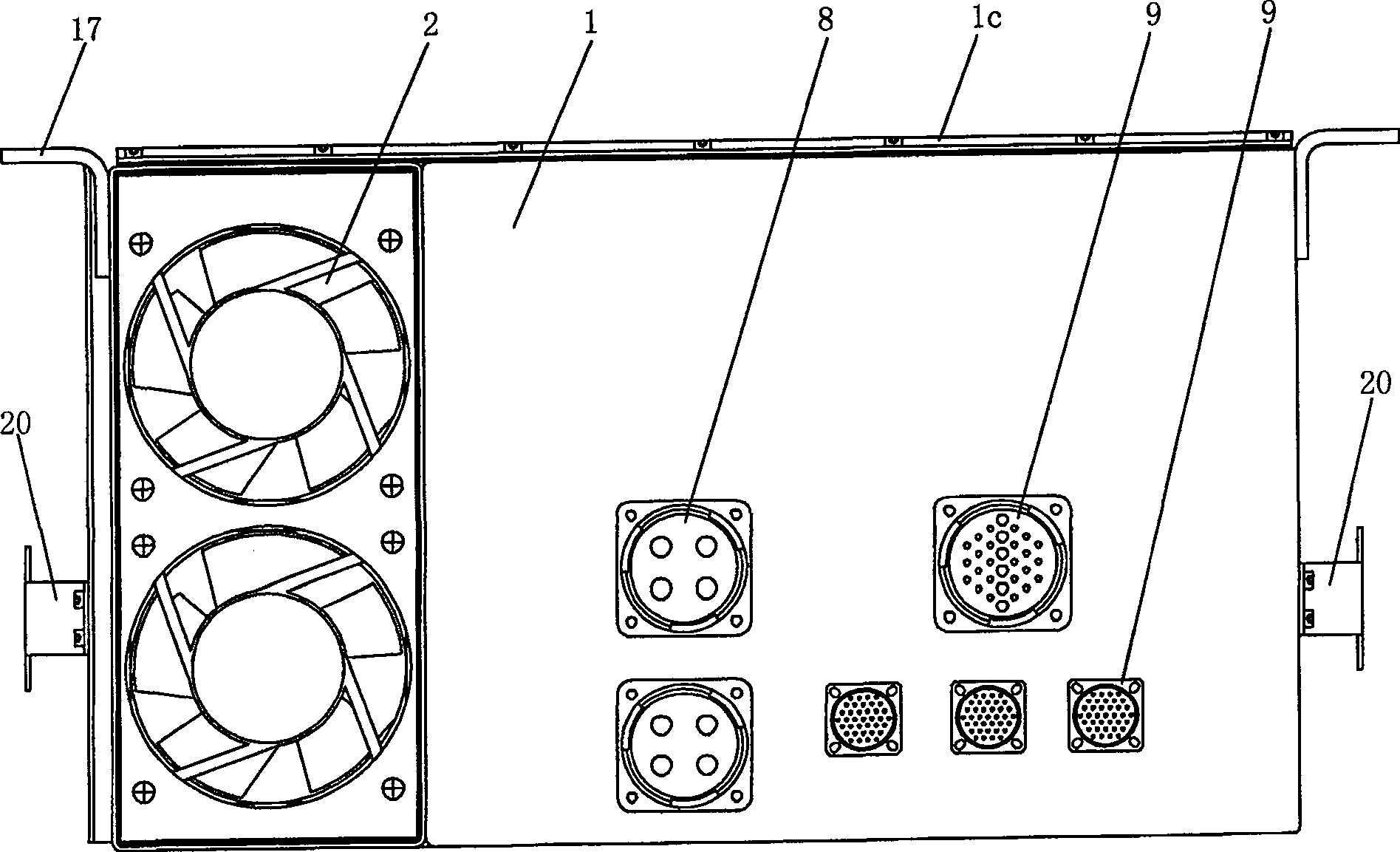

[0039] figure 2 It is shown that a strong electric connector 8 and a weak electric connector 9 are fixedly installed on the front panel of the space on the right side of the laminated power busbar 5 of the box body 1 in this example, and the strong electric connector 8 is located on the left of the weak electric connector 9 .

[0040] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com