High-intensity discharge lamp of compact type with bulb holder

A high-intensity discharge lamp, compact technology, applied in the direction of discharge lamps, gas discharge lamp parts, discharge tubes, etc., can solve the safety problems of lamp reliability ballasts, distributed capacitance and inductance trigger pulse leakage, influence Lighting reliability and other issues, to achieve the effect of firm and reliable circuit boards and the entire structure, improved thermal shock and mechanical vibration resistance, and safe and reliable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment content of the present invention is described in further detail:

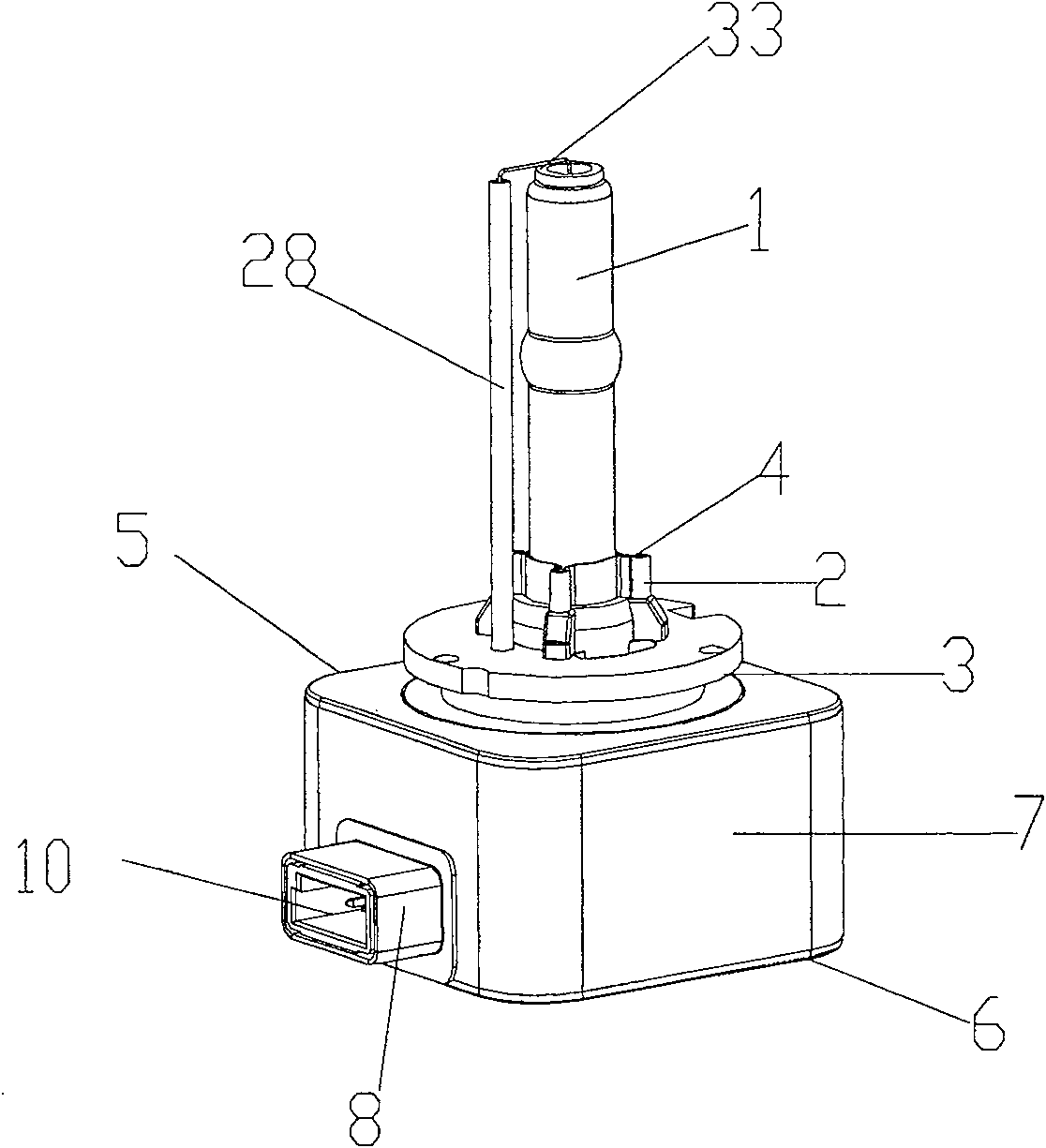

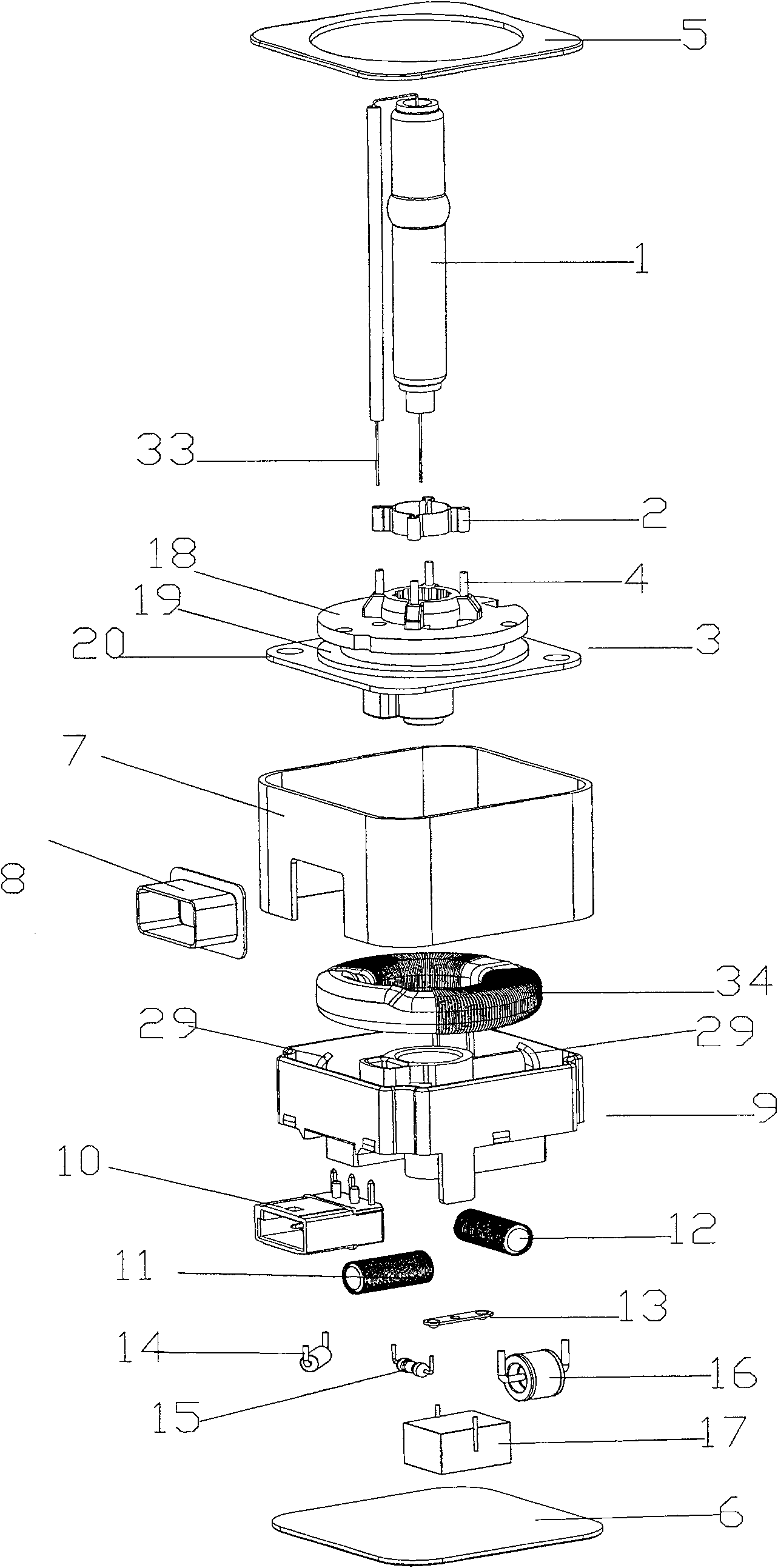

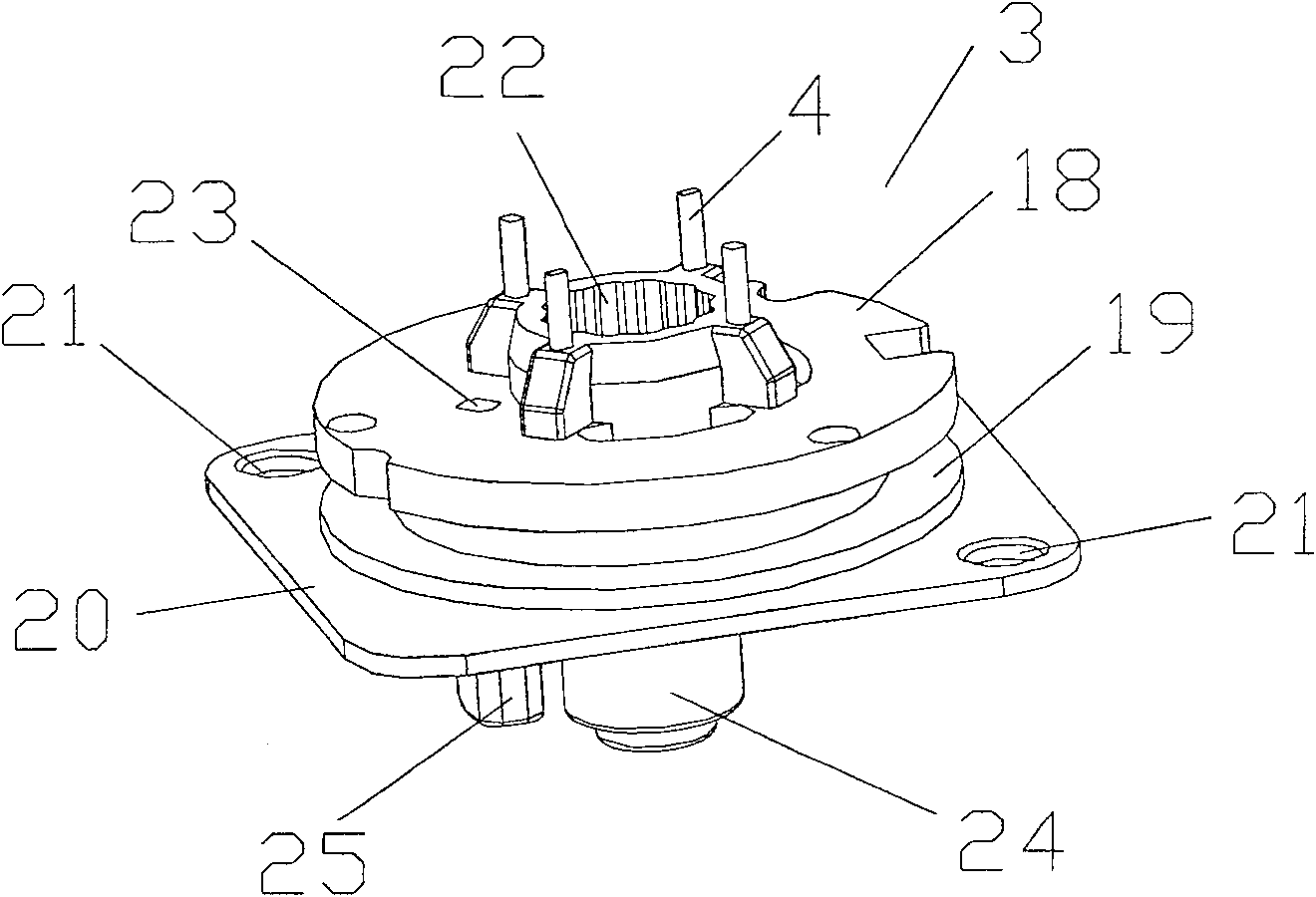

[0027] Such as figure 1 , 3 As shown, the present invention fixes the small high-intensity discharge lamp 1 in the discharge lamp tube fixing groove 22 of the lamp base carrier 3. The lamp base carrier 3 has a fixing pin rod 4 for fixing the bulb and embedded in the lamp base and is firmly welded on In addition to the lamp tube clamping ring 2 on the fixing pin, there is also a datum plane locating plate 18 and a datum reference plate 19 for positioning the lamp as a datum plane and matched with the lamp. The distance d set between the datum plane locating disc 18 and the datum reference disc 19 is exactly the width of the lamp tube fixing snap ring. Below the reference plate 19 is an insulating trigger module upper cover plate 20. There is a glue injection hole 21 on the trigger module upper cover plate 20. The center of the lamp cap is a lamp tube fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com