Completely degradable water retaining mulching of fruit residue humic acid and its production process

A humic acid and full-degradation technology, applied in plant protection covers, etc., can solve problems such as slightly worse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After adding 100 grams of apple pomace after extracting polyphenolic compounds, 2 times the weight of water, 0.003 grams of ammonium sulfate, 0.002 grams of dipotassium hydrogen phosphate, 0.001 grams of potassium chloride and 0.005 grams of starch nutritional compounds, and After 3 minutes of UV irradiation, inoculate 3.1×10 5 cfu / ml of Trichoderma and 1.2 x 10 5 The mixture of Aspergillus niger spores of cfu / ml was prepared at 30°C for 48 hours to prepare liquid strains;

[0026] Put 65 grams of crushed reed stems and leaves, and 35 grams of apple pomace mixture after extracting polyphenol compounds into 0.02 times the weight of liquid bacteria, and under anaerobic conditions, solid-state fermentation at 25 ° C; made after 7 days Highly active BHA containing IAA and other components;

[0027] Mixing 38 grams of high-activity BHA with 62 grams of starchy industrial waste residue, etc., to make a semi-finished film with a viscosity of 80,000 centipoise. The industrial...

Embodiment 2

[0030] Adopt the same method of embodiment 1, wherein:

[0031] Add 33 grams of apple pomace after extracting polyphenolic compounds to the pulverized plant barley in a weight ratio of 1:3, add 10 times the weight of water, inoculate yeast spores, and conduct solid-state fermentation at 20°C under anaerobic conditions ; After 10 days, high-activity BHA containing ABA and other components was made.

[0032] (3) Mix highly active BHA with 5 grams of polyvinyl alcohol film-forming agent of 0.2-10 mg / L, 0.3 gram of palmitic acid thickener, and 0.1 gram of salicylic acid antioxidant, and adjust it to be stable at 40 ° C. , the semi-finished product with a viscosity of 50,000 centipoise is sprayed on the site to be covered to form a fully degradable water-retaining plastic film with a thickness of 0.12mm;

Embodiment 3

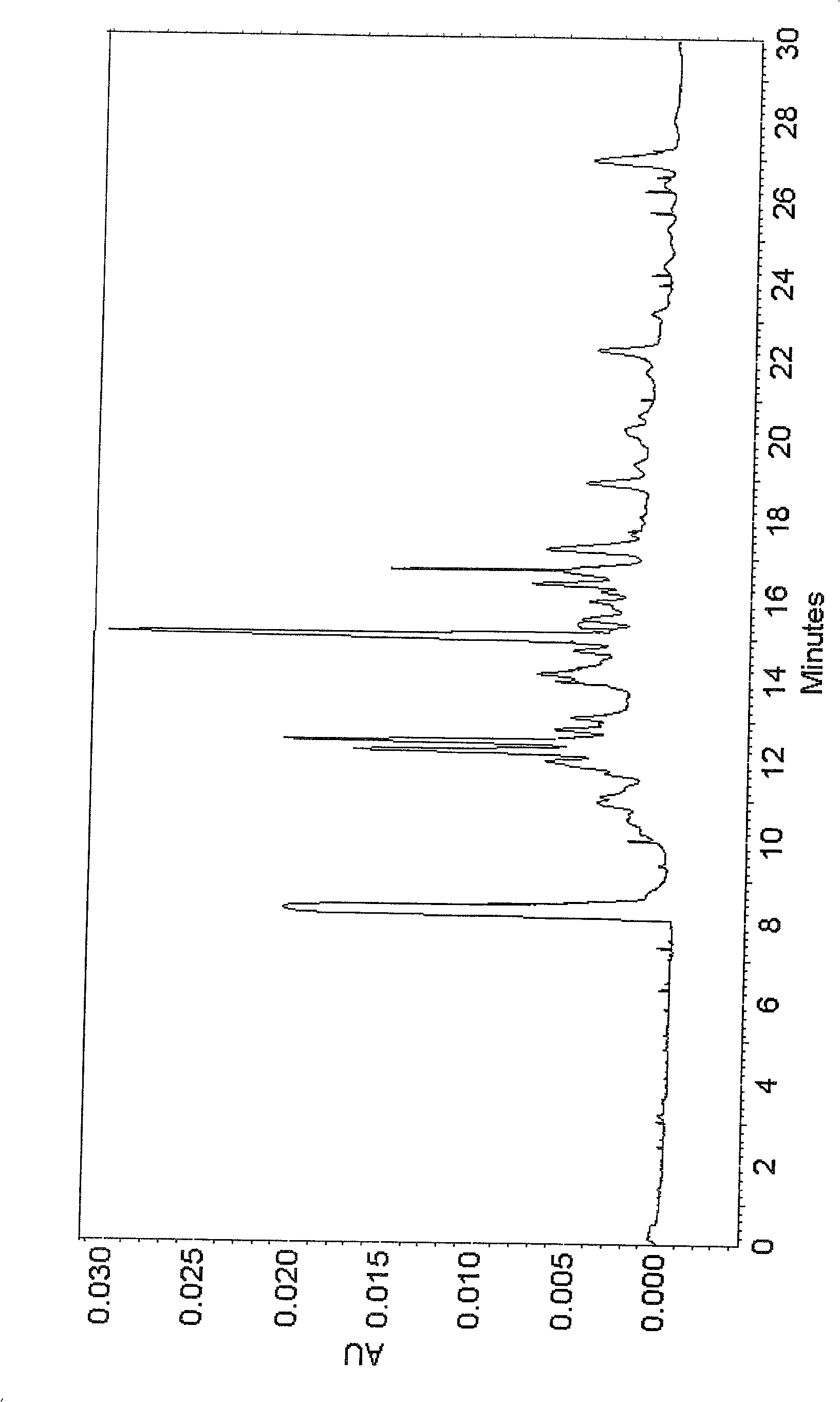

[0034] After the secondary apple pomace after extracting polyphenols is mixed with wild reed broken leaves, according to the liquid strain expansion cultivation method of implementation 1, it is solid-state fermented at 30 ° C, and after 6 days, it is made into IAA, ABA and other components. Highly active BHA (see attached figure 1 ); Then make the semi-finished mulch film by implementing 2.

[0035] 200 grams of said semi-finished products are added on the spot with 3 grams of PVA anionic surfactants with a concentration of 10 mg / L, and sprayed on the field; after film formation, the thickness of the mulch layer on the soil surface is measured to be 0.15 mm; within 3 months After that, it can be completely degraded into humic acid fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com