Track support for building machinery

一种建筑机械、履带架的技术,应用在履带架领域,能够解决清洗的费用增大、上转轮偏磨损、旋转轴承损伤等问题,达到减轻重量、减少焊接部位、提高焊接强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

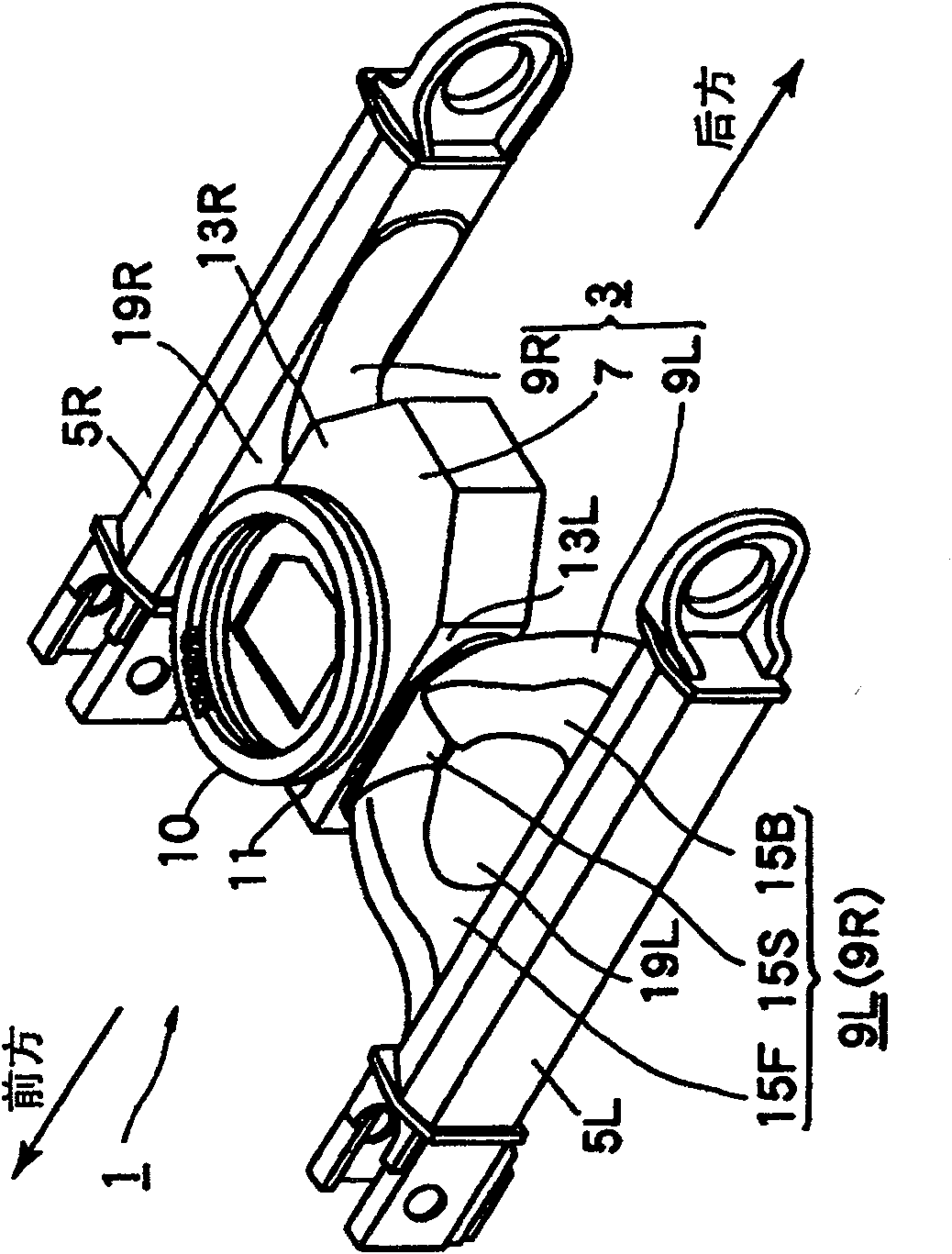

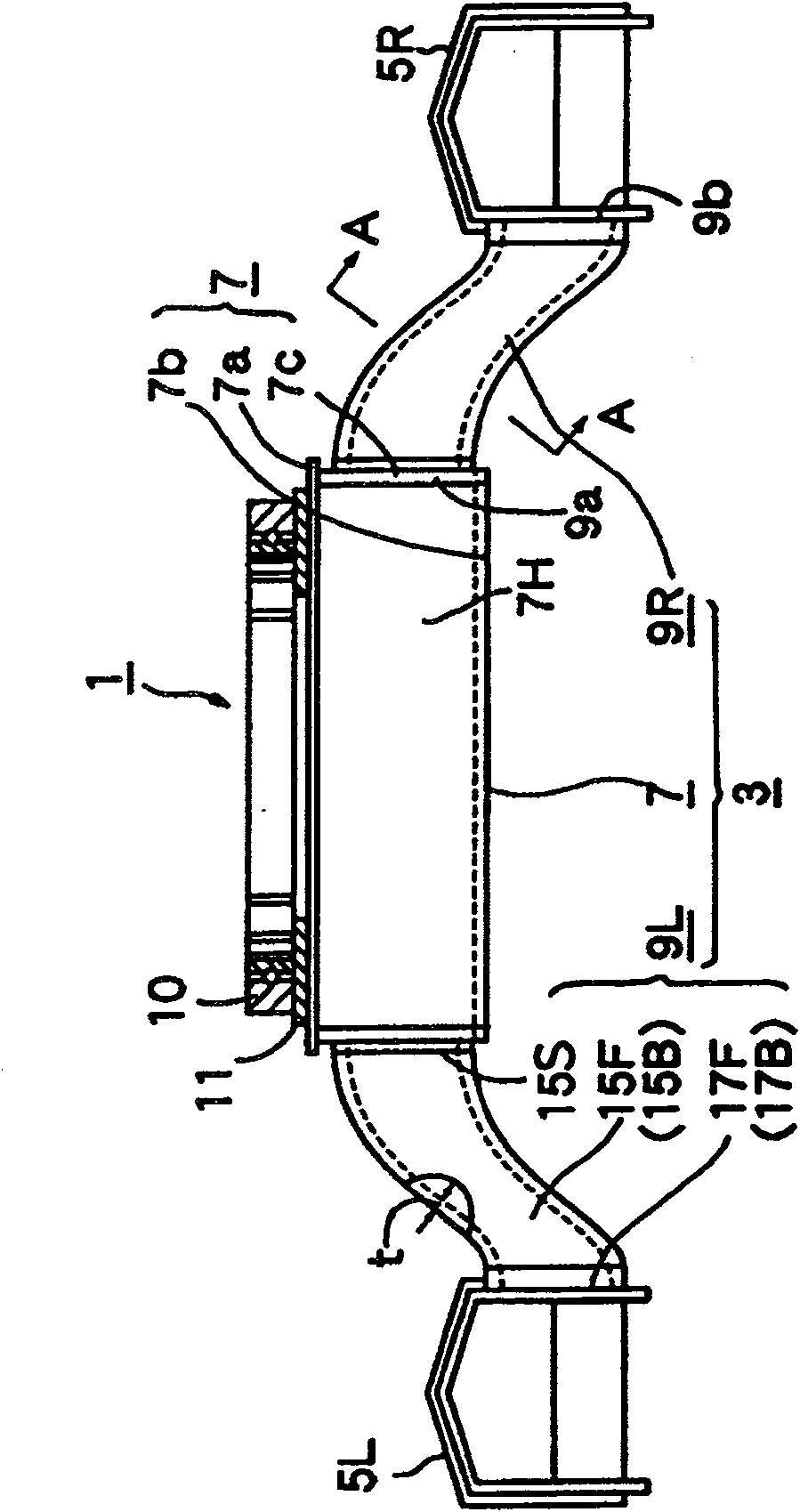

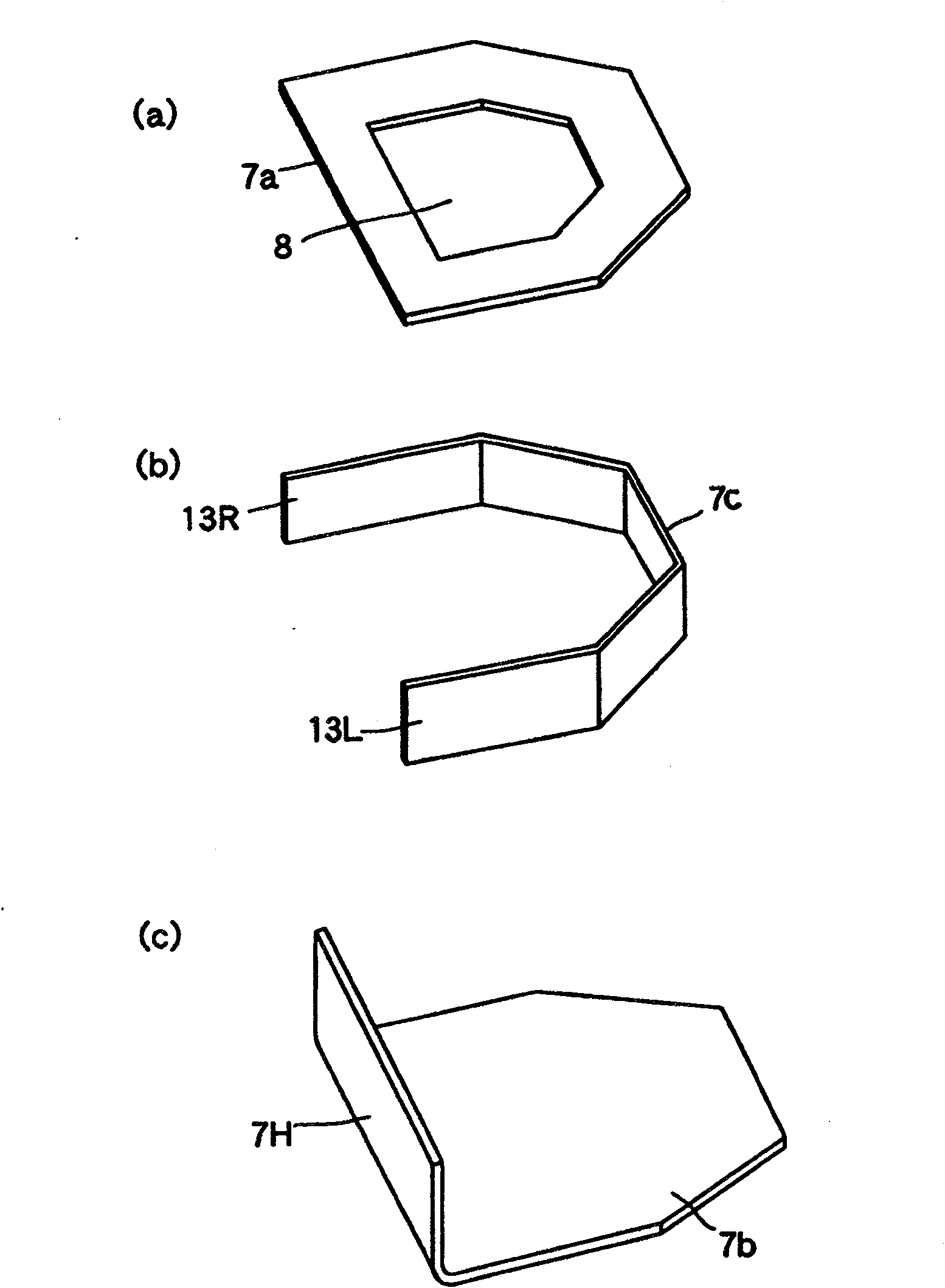

[0045] The specific implementation of the crawler frame of the construction machine in the present invention will be described below with reference to the accompanying drawings.

[0046] First, use Figure 1 to Figure 5 A crawler frame for a construction machine according to a first embodiment of the present invention will be described.

[0047] figure 1 It is an external perspective view of the crawler frame of the construction machine according to the first embodiment of the present invention, figure 2 It is a front view of the crawler frame of the construction machine according to the first embodiment of the present invention, image 3 (a), (b) and (c) are development views of the center frame portion of the center frame of the track frame of the construction machine according to the first embodiment of the present invention, Figure 4 It is an external side view of a leg of a center frame of a crawler frame of a construction machine according to a first embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com