Crane hoist trolley for easy maintenance

A hoisting trolley and crane technology, applied in the direction of load trolley, load hanging element, transportation and packaging, etc., can solve the problems of safety risk, failure to achieve full closure, low maintenance efficiency, etc., to improve the average force, avoid The wheel line error is too large and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

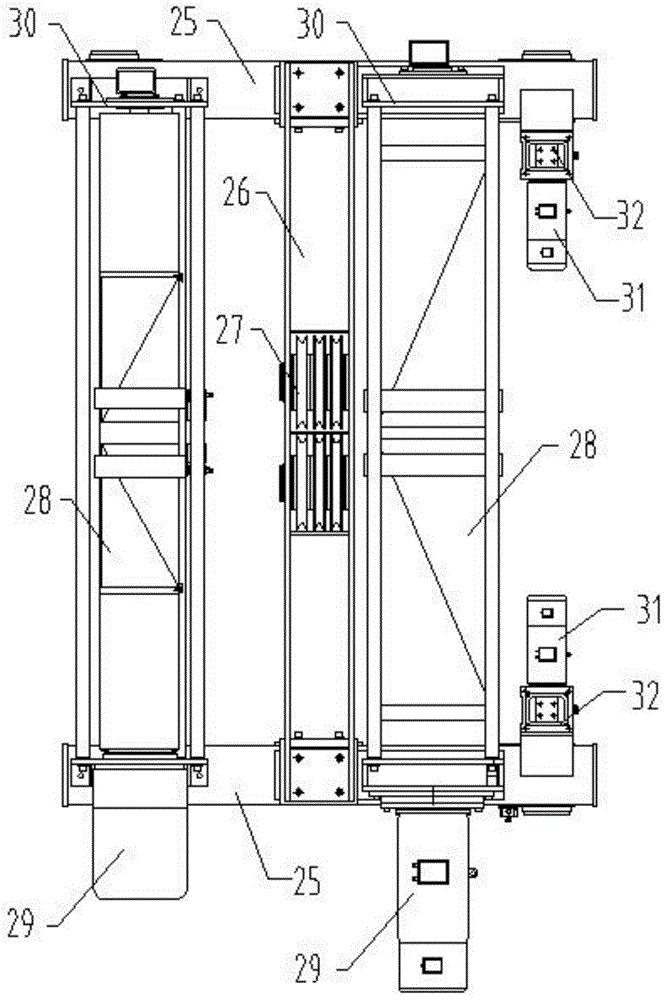

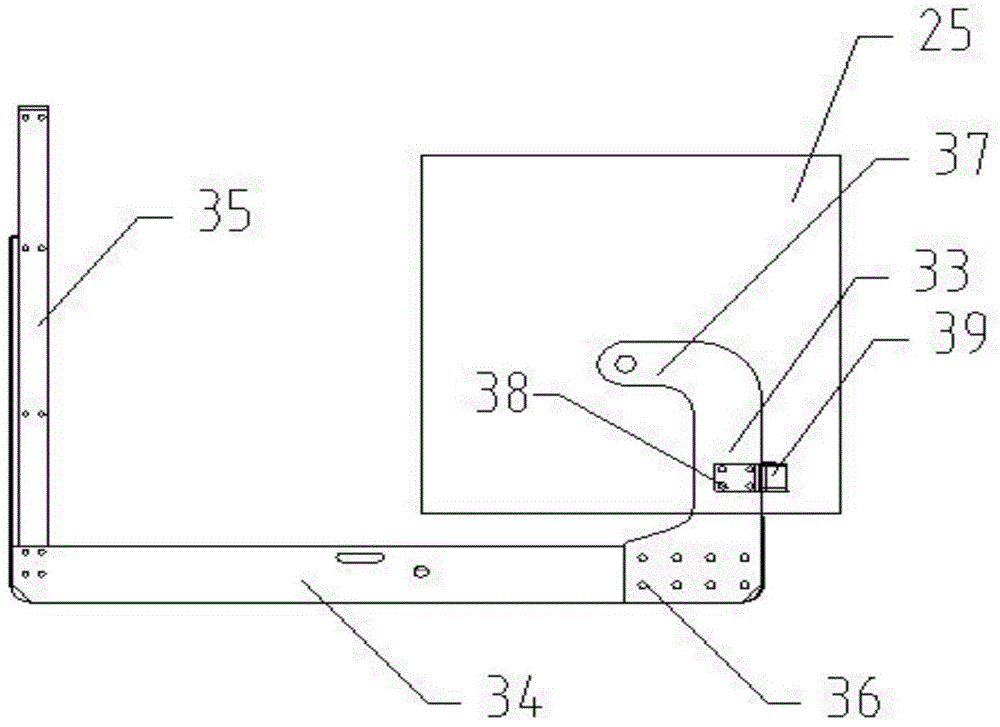

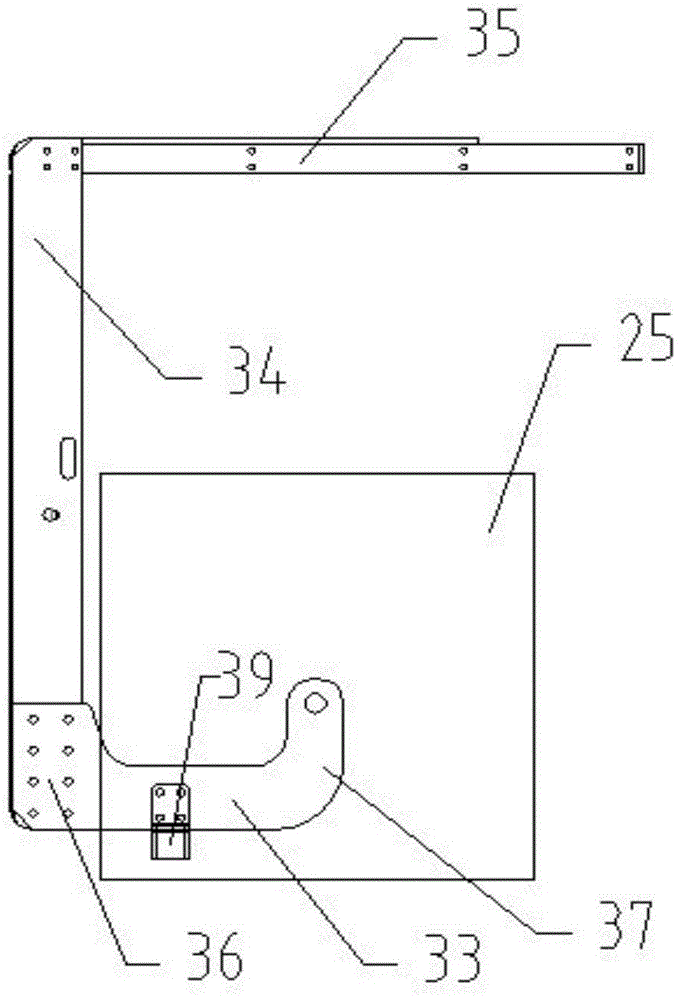

[0020] Such as Figure 1 to Figure 8 As shown, the easy-to-maintain crane trolley of the present invention includes a trolley and special monitoring equipment arranged on the trolley.

[0021] The lifting trolley includes a trolley frame and a hoisting module, a walking module and a movable maintenance platform arranged on the trolley frame. The trolley frame includes two walking beams 25 arranged in parallel, and the two walking beams 25 The middle part is fixed with a load-bearing beam 26 by bolts, and the two walking beams 25 and the load-bearing beam 26 are arranged in an I-shape, which can not only ensure the reliability and versatility of the connection between the two walking beams 25 and the load-bearing beam 26, but also effectively reduce welding position, avoiding the phenomenon that the wheel line error of the lifting trolley is too large due to welding deformation. The load beam 26 is provided with a fixed pulley block 27 . The hoisting module includes two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com