Air cannon block-removing equipment of micro-recoil

A recoil and air cannon technology, applied in the field of block cleaners, can solve the problems of scrapping block cleaners, easily broken, frequent equipment replacement, etc., and achieve the effect of improving and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

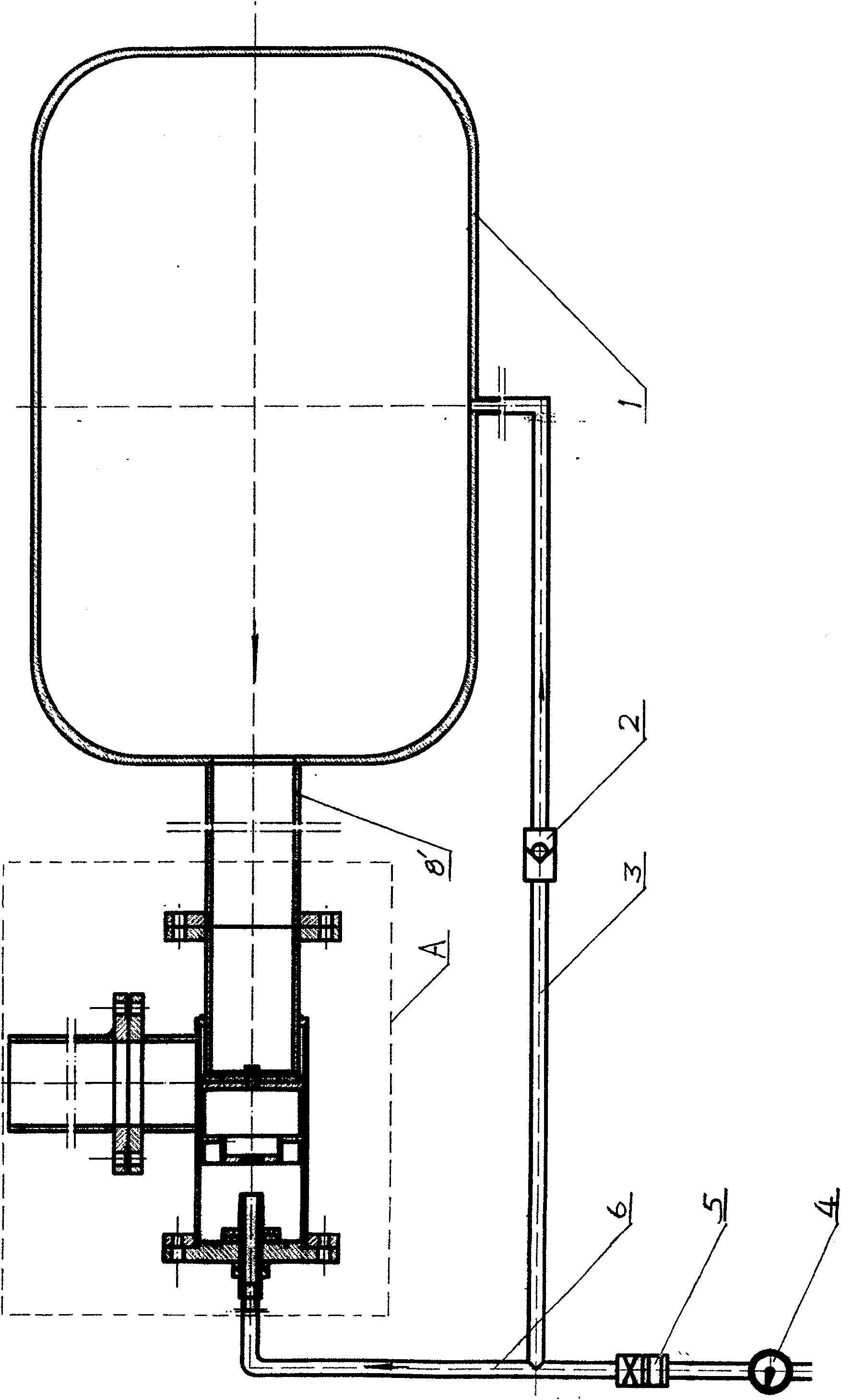

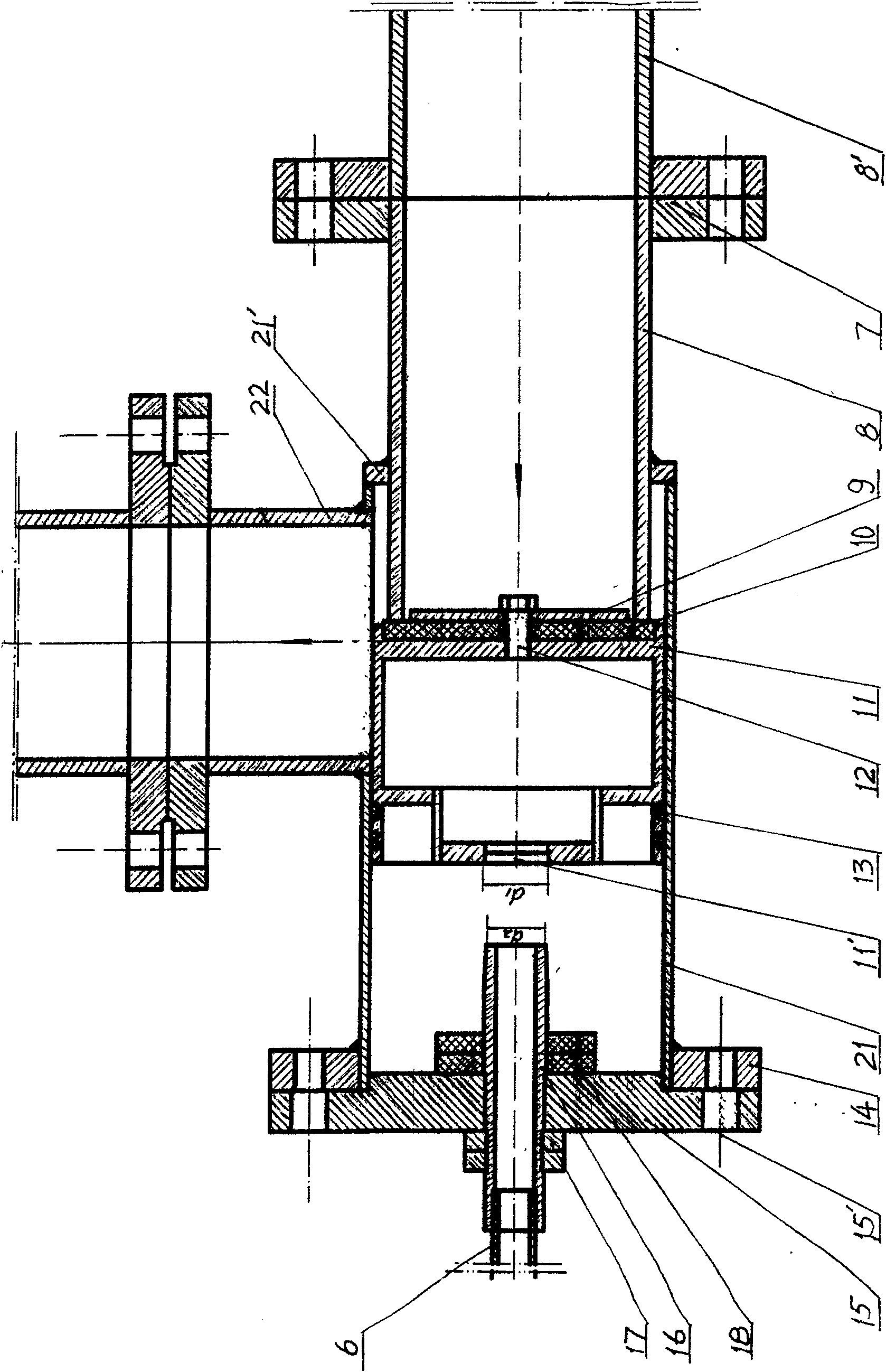

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] as attached figure 1 As shown, the pressure reducing valve 4 (the specification and model can be selected from 0-1 / 2MPa) connected to the air compressor outlet or the air pipeline of the air compressor station is connected to the reversing valve 5 (the specification and model can be selected from K230-2T) The inlet end of the reversing valve 5 and the outlet end of the reversing valve 5 are connected to one end of the intake pipe 6, and the air delivery pipe 3 drawn from the intake pipe 6 is connected to the storage tank through the check valve 2 (the specification and model can be selected from KA-L15, 0.05-0.8MPa). Bubble 1, the other end of inlet pipe 6 is connected with plunger coil 16, and the connection mode of described inlet pipe 6 and plunger coil 16 is best selected from internal thread connection (as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com