Implementing method for back photoelectric smoke induction investigator and its device

A technology of photoelectric smoke and realization method, applied in instruments, alarms, fire alarms, etc., can solve the problems of insensitivity to black smoke, inability to alarm, lens deformation, etc., to achieve stable detection sensitivity, maximum detection area, intersection The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

illustration:

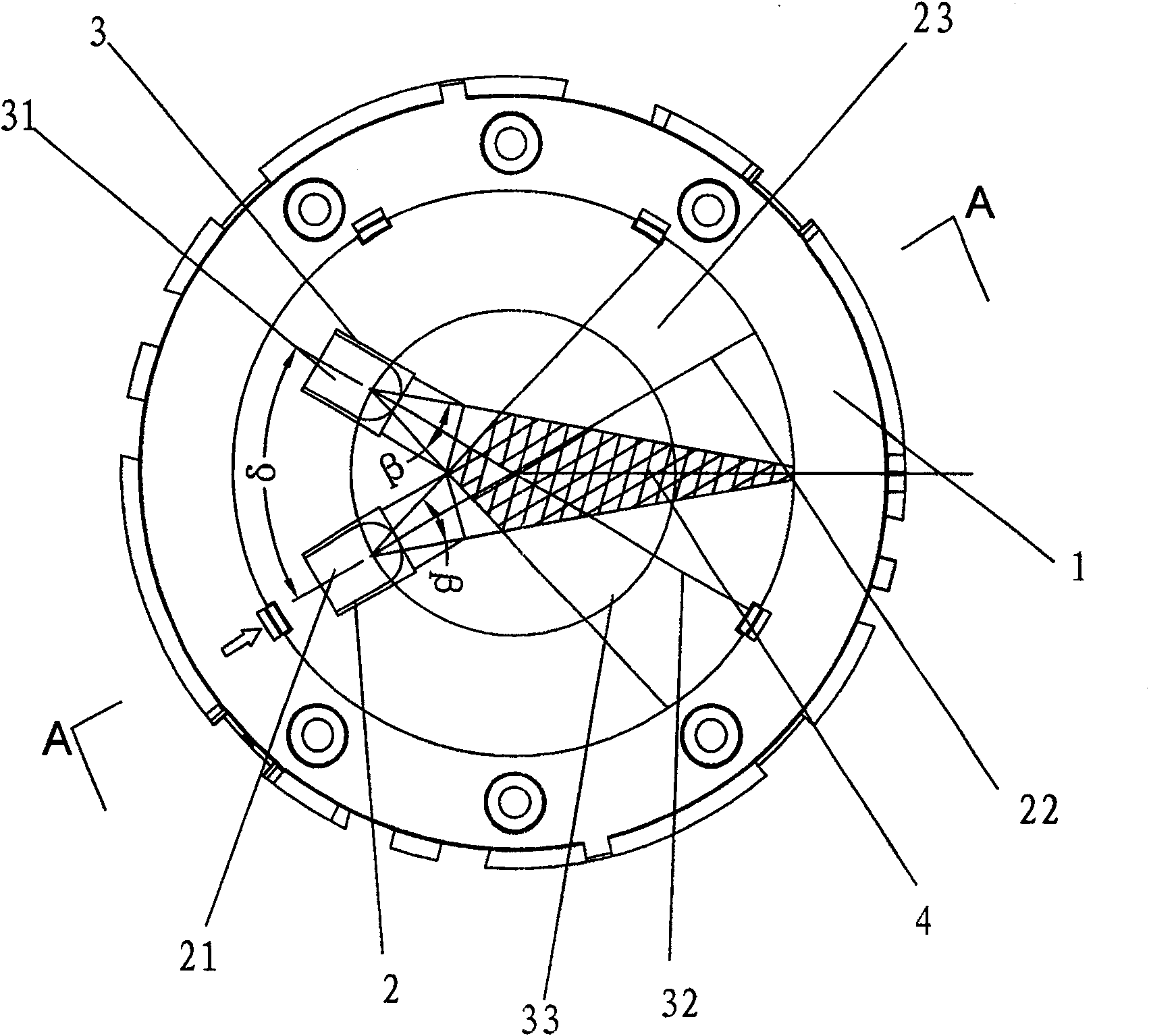

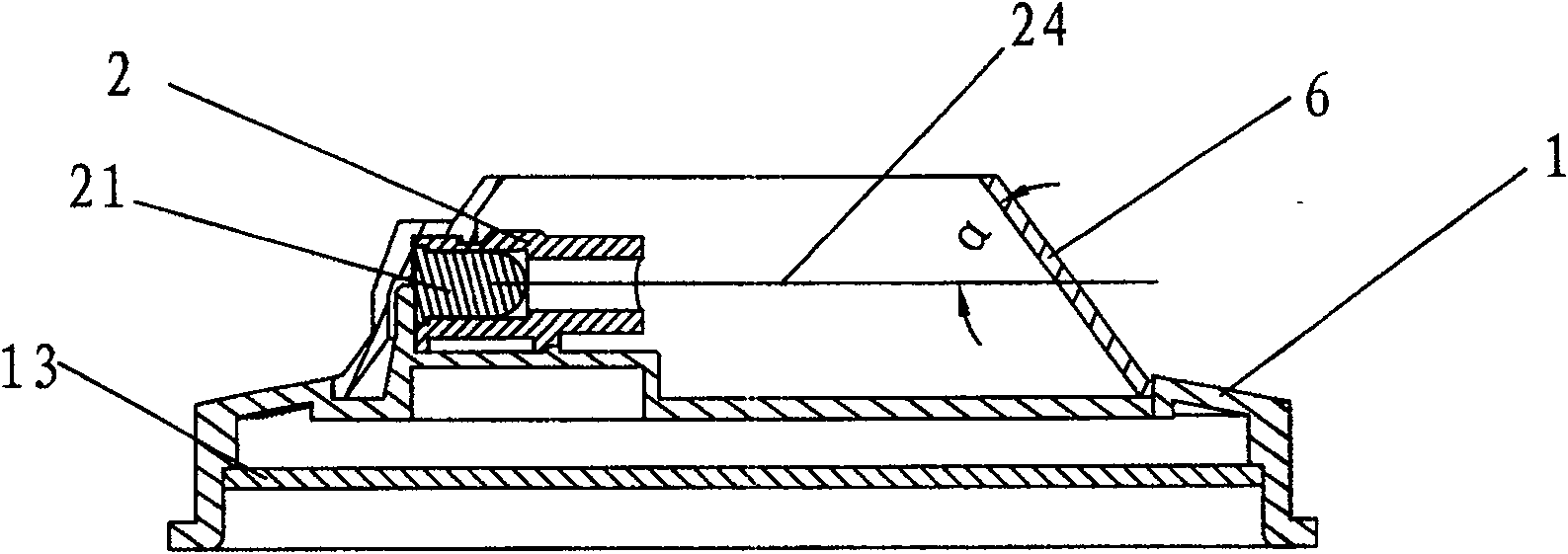

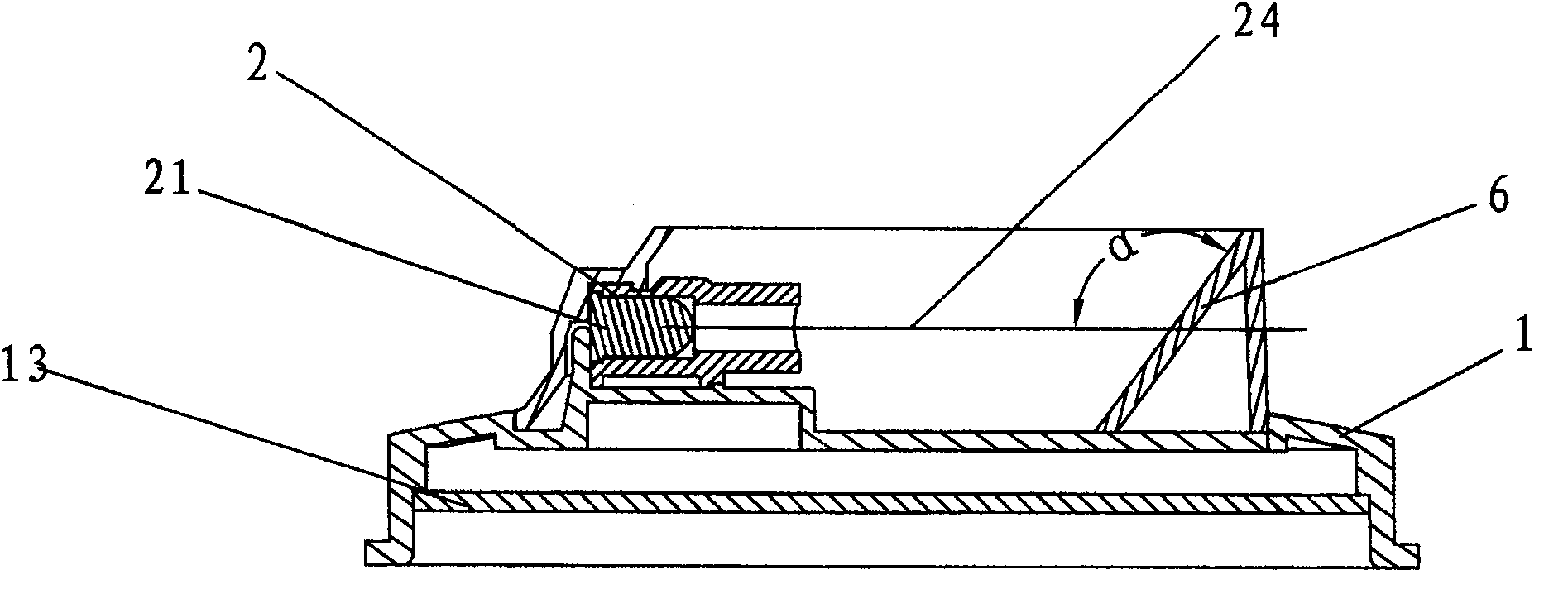

[0034]1. Base; 2. Emitting light guide; 21. Light emitter; 22. Central axis of light emitted by the light emitter; 23. Emitting light path; 24. Light plane; 3. Receiving light guide; 31. Light receiving 32. Optical central axis of the light received by the optical receiver; 33 receiving optical path; 4. Detection area; 5. Insect net; 51. Smoke guide bracket; Rib; 63, inner rib; 64, groove; 65, top surface of hood; 7, upper cover; 71, smoke inlet hole of upper cover; 8, light guide column; 9, rear cover; 10, screw; 11, terminal block; 12. Mounting seat; 13. Circuit board.

[0035] Combine below Figure 1 to Figure 3 , to illustrate the realization method of the backward photoelectric smoke detector of the present invention.

[0036] See figure 1 , figure 2 and image 3 , as can be seen from the figure, in the dark room that is made of shading cover 6 and base 1, be provided with the receiving light path 23 by light emitter 21 (infrared LED emitting tube ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com