Control circuit for power converter

A power converter and control circuit technology, applied in output power conversion devices, conversion of DC power input to DC power output, control/regulation systems, etc., can solve problems such as low-pass filtering characteristics and waveform distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to enable the examiner to have a better understanding and understanding of the structural features and achieved effects of the present invention, I would like to provide a diagram of a better embodiment and a detailed description, as follows:

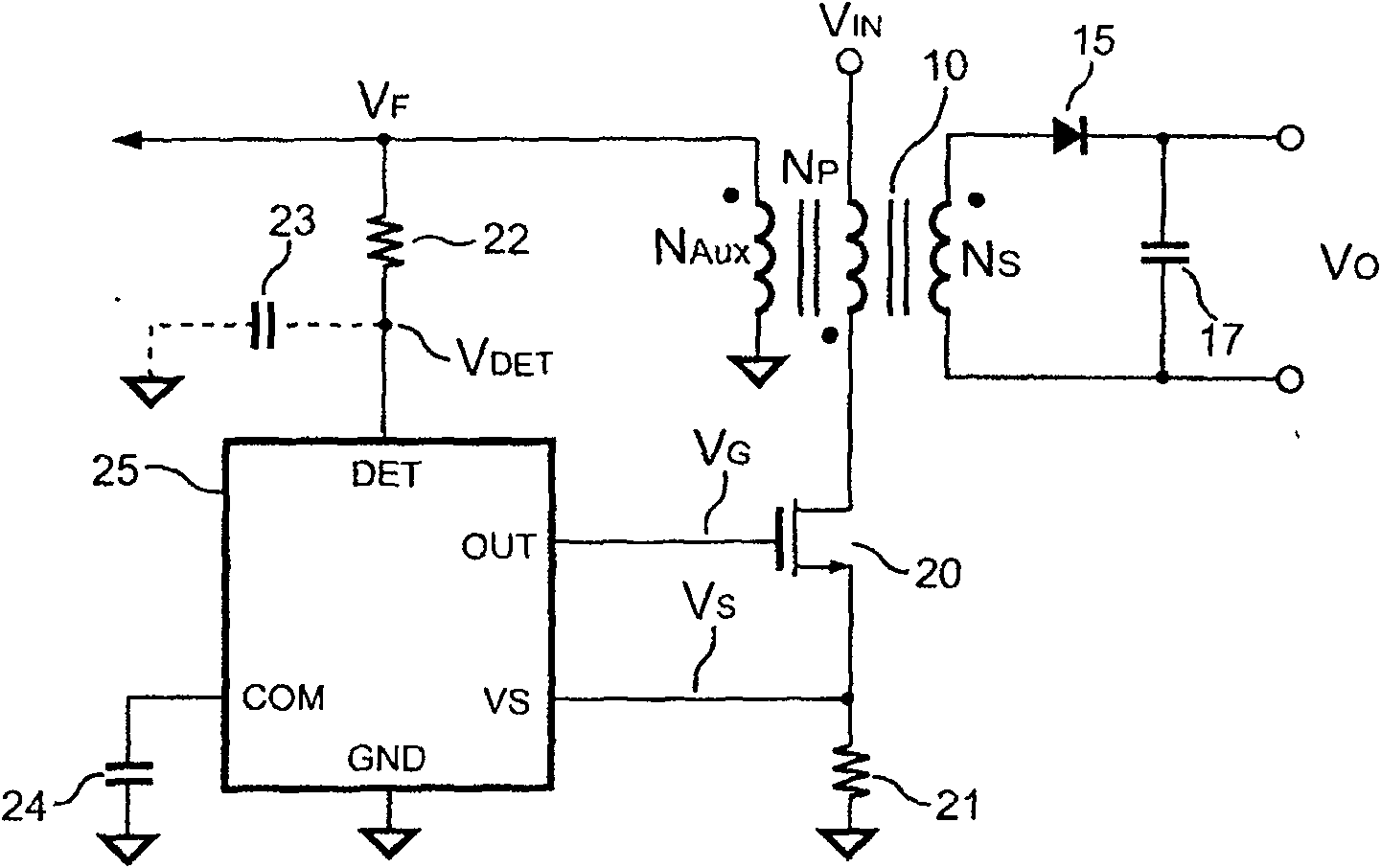

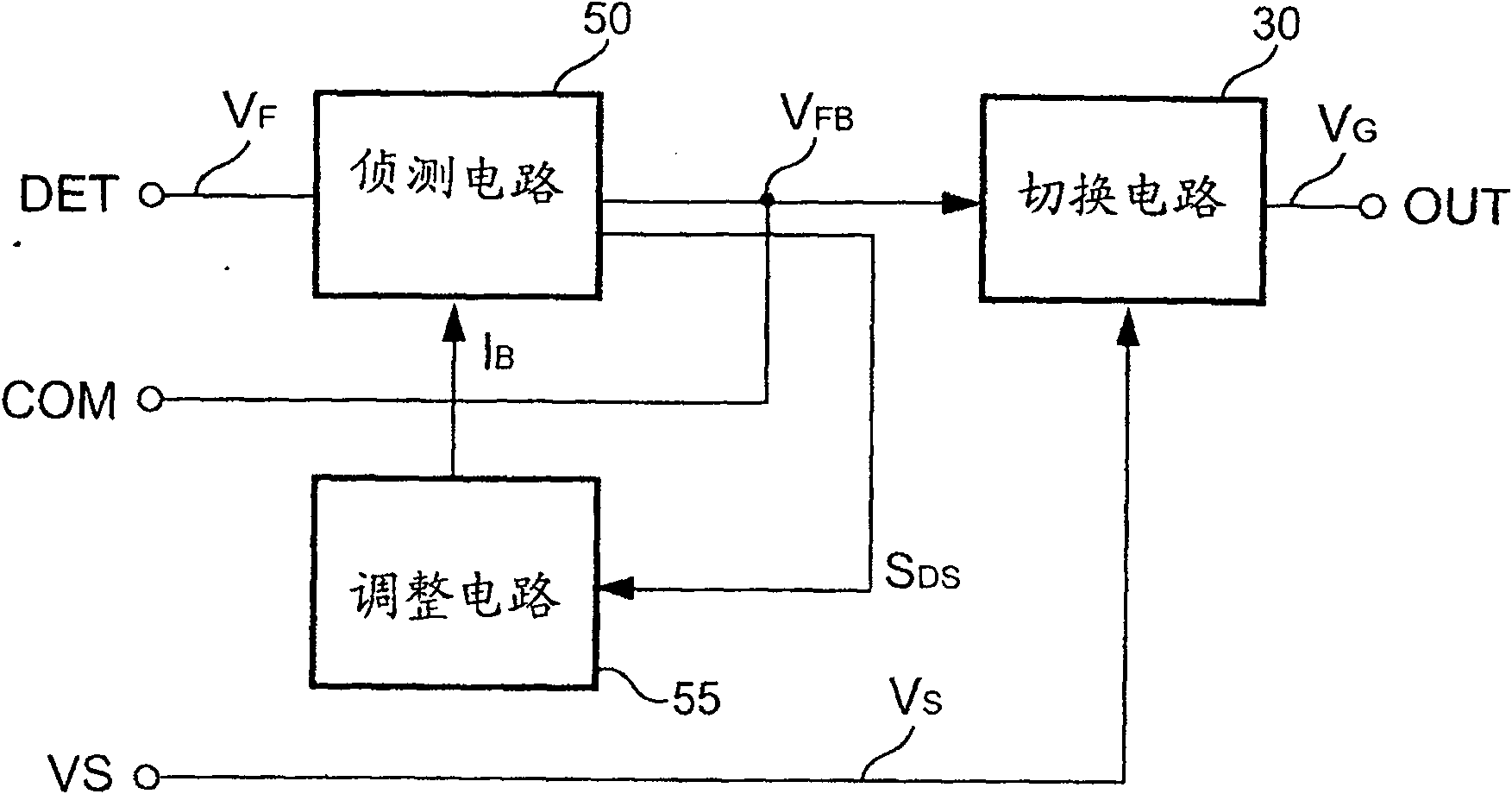

[0063] The control circuit of the power converter of the present invention includes a switch and a controller. The controller generates a control signal to control the coupled switch to switch the transformer of the power converter. see image 3 , is a block diagram of a controller of a preferred embodiment of the present invention. As shown in the figure, the controller of the present invention includes a switch circuit 30 , a detection circuit 50 and an adjustment circuit 55 . The detection circuit 50 is coupled to the transformer 10 via the voltage detection terminal DET to detect the feedback voltage V of the transformer 10 F , to depend on the feedback voltage V F generate a first signal V FB and a second signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com