Design construction method of rectangular infiltration gallery for stabling water volume

A rectangular, seepage canal technology, applied in the seepage canal field, can solve the problems of cut-off and poor water flow in seepage canals, and achieve the effects of fast flow rate, good water intake effect and stable water volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

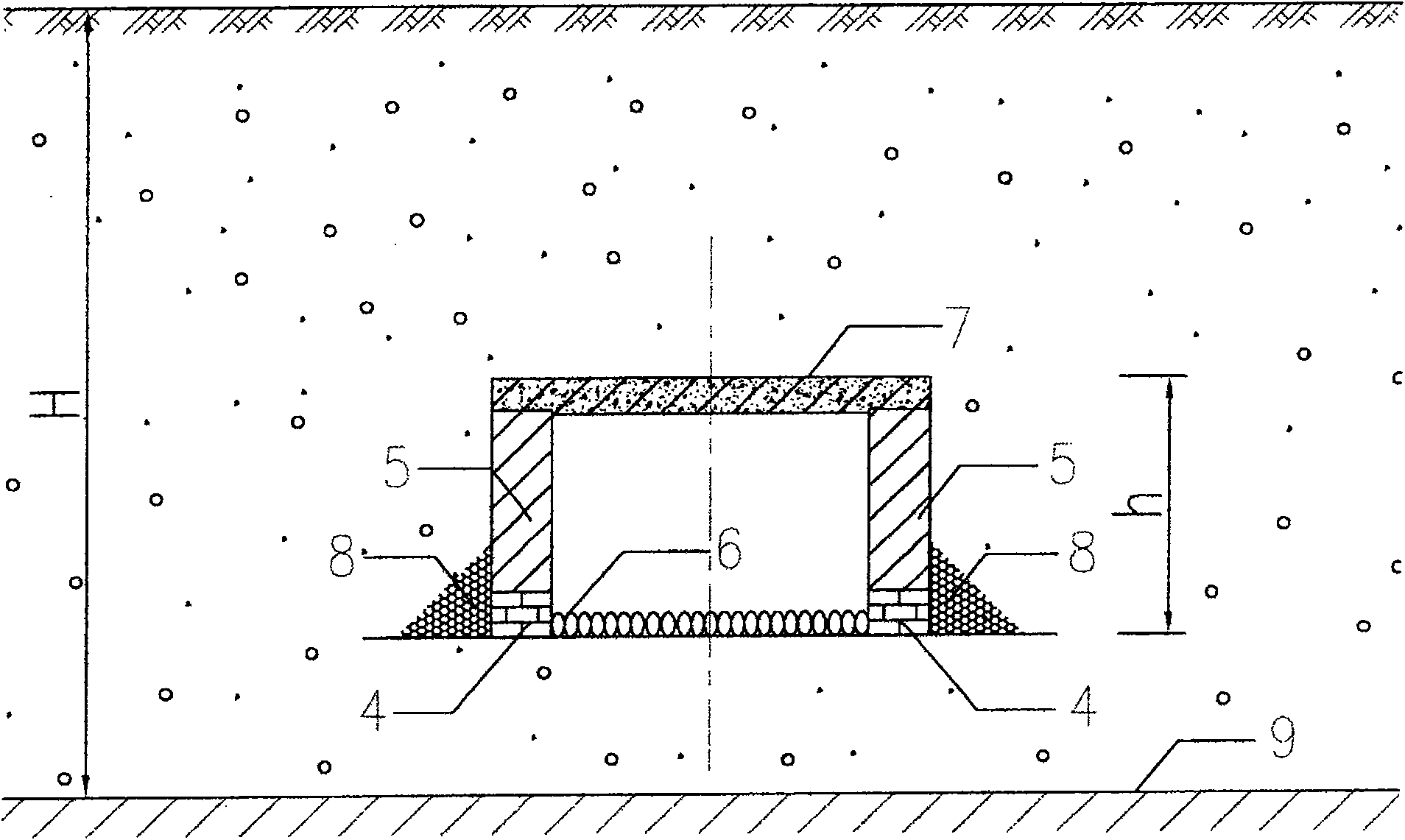

[0035] Such as image 3 The method for designing and constructing a rectangular seepage trench without digging into the aquifer bottom plate in the aquifer includes the following steps:

[0036] (1) Excavation: excavate the soil layer or sand and pebble layer to the design depth (elevation), but do not dig into the aquifer floor 9 in the aquifer;

[0037] (2) Dry masonry: Strip bricks, cement prefabricated blocks or strip stones are dry masonry arranged on the lower part of the two side walls of the rectangular seepage trench, with at least one horizontal joint and at least one vertical joint intersecting to meet the design requirements The water inlet slit array 4 of height, the slit of described water inlet slit array is maximum 3mm, and it is characterized in that horizontal slit and vertical slit only enter water and do not enter sand pebble. Therefore, the water output will not be reduced;

[0038] (3) Mortar masonry: the upper part of the dry masonry inlet joint array ...

specific Embodiment approach 2

[0042] Such as Figure 4 The method for designing and constructing the rectangular seepage channel of the aquitard floor dug into the aquifer shown in the aquifer includes the following steps:

[0043] (1) Excavation: the design depth (elevation) of excavating the soil layer or gravel and pebble layer should be dug to the aquifer floor 9 in the aquifer;

[0044] (2) Dry masonry: Strip bricks, cement prefabricated blocks or strip stones are dry masonry arranged on the lower part of the two side walls of the rectangular seepage trench, with at least one horizontal joint and at least one vertical joint intersecting to meet the design requirements The water inlet slit array 4 of height, the slit of described water inlet slit array is maximum 3mm, and it is characterized in that horizontal slit and vertical slit only enter water and do not enter sand pebble. Therefore, the water output will not be reduced;

[0045] (3) Mortar masonry: the upper part of the dry masonry inlet joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com