Composite floor surface layer, composite floor and manufacturing method thereof

A manufacturing method and technology for composite floors, which are applied in the directions of manufacturing tools, wood-layered products, chemical instruments and methods, etc., can solve the problems of poor anti-fouling, easy formation of dead zones, and increased pulp of composite floors, so as to achieve enhanced anti-fouling properties. The effect of pollution ability, high wear resistance, high pollution resistance and high simulation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The surface layer of composite floor is composed of decorative wear-resistant paper and surface anti-fouling paper. The decorative wear-resistant paper is a decorative paper impregnated with resin and evenly distributed with aluminum oxide particles. The surface anti-fouling paper is wood pulp fiber impregnated with resin. Paper.

[0037] The particle size of aluminum oxide is 180-280.

[0038] The resin is melamine resin or other resins with the same function as melamine resin.

[0039] Decorative paper is 70 g / m 2 , wood pulp fiber paper is 10-15 g / m 2 .

Embodiment 2

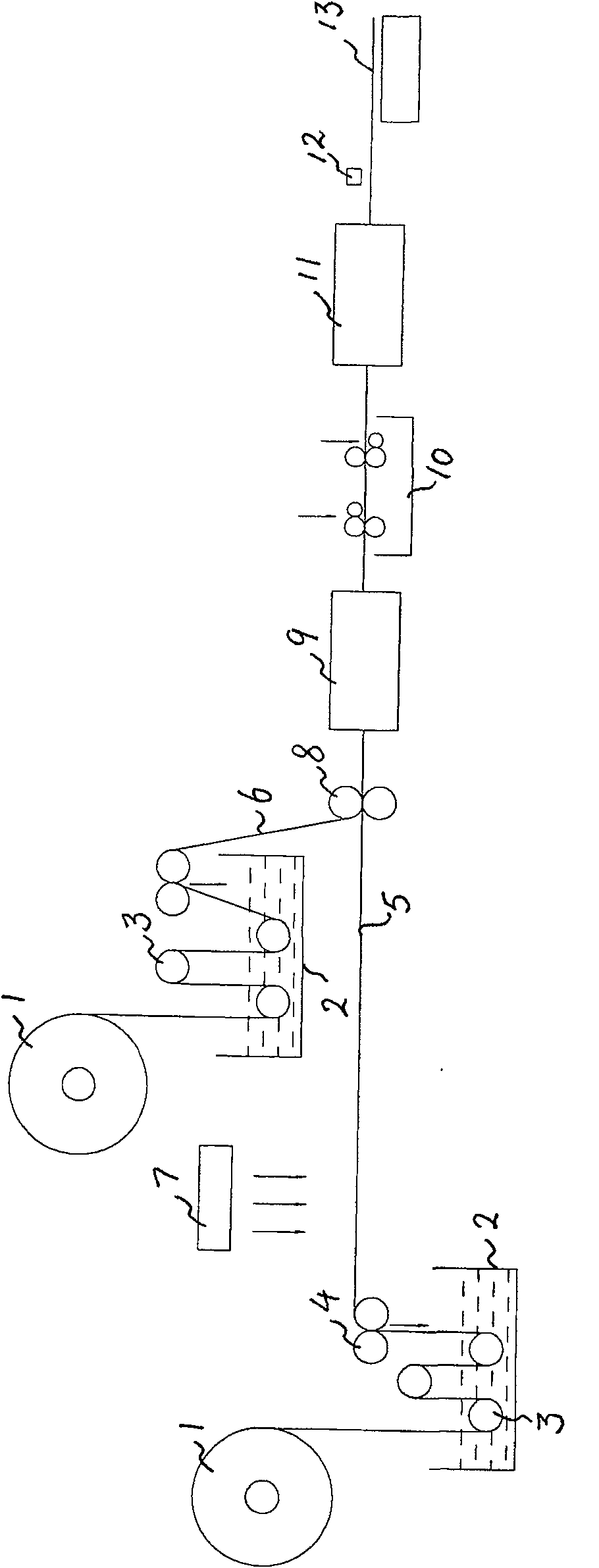

[0041] Such as figure 1 Shown, the manufacturing method of composite floor surface layer, concrete technological process is:

[0042] A. The decorative paper roll is guided from the paper rack to the impregnation tank by the guide roller. After impregnation, the impregnation quantitative control is carried out by the quantitative roller, and then the lower sander sprinkles aluminum oxide particles on the decorative paper to obtain decorative wear-resistant paper. ;

[0043] B. The wood pulp fiber paper roll is guided from the paper rack through the guide roller into the impregnation tank for impregnation to obtain surface anti-fouling paper;

[0044] C. The decorative wear-resistant paper and the surface anti-fouling paper are laminated together by composite rolls and enter the first heat-sealed drying oven for drying;

[0045] After steps D and C, the laminated decorative wear-resistant paper and surface anti-fouling paper are quantitatively sized by a secondary surface siz...

Embodiment 3

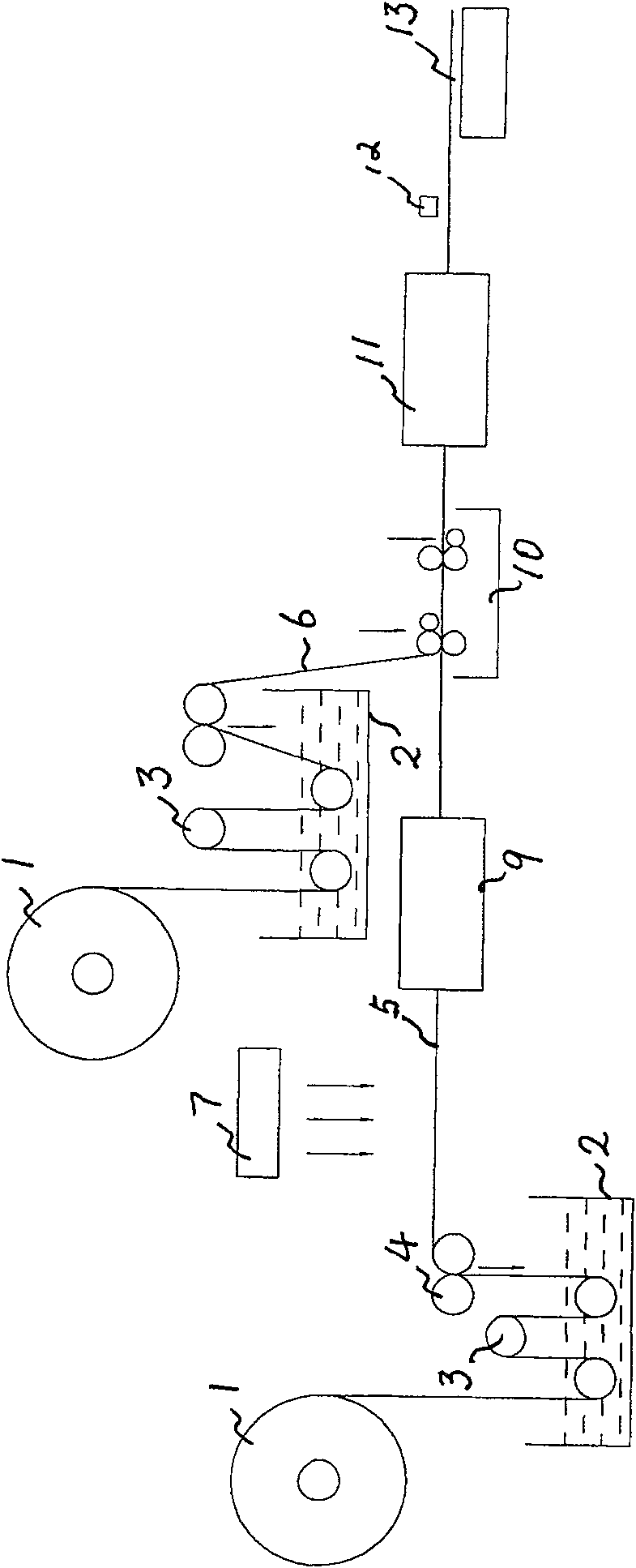

[0047] Such as figure 2 Shown, the manufacturing method of composite floor surface layer, concrete technological process is:

[0048] A. The decorative paper roll is guided from the paper rack to the impregnation tank by the guide roller. After impregnation, the impregnation quantitative control is carried out by the quantitative roller, and then the lower sander sprinkles aluminum oxide particles on the decorative paper to obtain decorative wear-resistant paper. ;

[0049] B. The wood pulp fiber paper roll is guided from the paper rack through the guide roller into the impregnation tank for impregnation to obtain surface anti-fouling paper;

[0050] C. The decorative wear-resistant paper enters the heat-seal drying oven to dry and then laminates with the anti-fouling paper.

[0051] After steps D and C, the superimposed decorative wear-resistant paper and surface anti-fouling paper are quantitatively sized by a secondary surface sizing coater and then enter the second heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com