A kind of preparation method of easy-to-pulp microcrystalline graphite negative electrode material

A technology of microcrystalline graphite and negative electrode materials, applied in the preparation/purification of carbon, graphite, battery electrodes, etc., can solve the problems of low cost performance and low yield of products, and achieve simple process, small specific surface area and good filling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

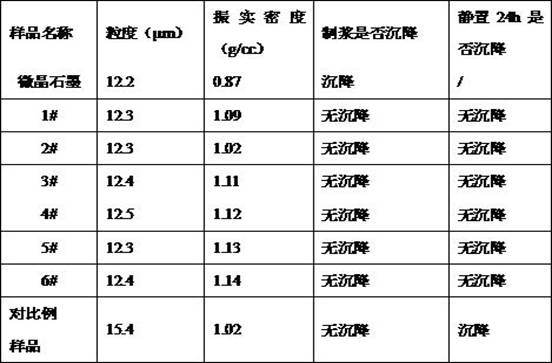

Examples

Embodiment 1

[0028] A1. Dissolve starch in deionized water, stir evenly to form a high molecular polymer solution, then pour the high molecular polymer solution into a hydrothermal reaction kettle filled with microcrystalline graphite particles, and mix well; among them, starch, deionized The mass ratio of ionized water and microcrystalline graphite particles is 10:500:100. Preferably, the microcrystalline graphite is spherical microcrystalline graphite with a particle size of 12 μm, which is produced in Chenzhou, Hunan.

[0029] A2. Heat the hydrothermal reactor to 160°C at a heating rate of 10°C / min, keep it warm for 12-48 hours, and then cool naturally to obtain water-soluble filled microcrystalline graphite particles.

[0030] A3. Vacuum filter the water-soluble filled microcrystalline graphite particles, and then dry them in an oven at a drying temperature of 120°C to obtain filled microcrystalline graphite particles.

[0031] A4. Then put the filled microcrystalline graphite particl...

Embodiment 2

[0034] A1. Dissolve cyclodextrin in deionized water, stir evenly to form a high molecular polymer solution, then pour the high molecular polymer solution into a hydrothermal reaction kettle filled with microcrystalline graphite particles, and mix well. Wherein, the mass ratio of cyclodextrin, deionized water and microcrystalline graphite particles is 20:500:100. Preferably, the microcrystalline graphite is spherical microcrystalline graphite with a particle size of 12 μm, which is produced in Chenzhou, Hunan.

[0035] A2. Heat the hydrothermal reactor to 120°C at a heating rate of 8°C / min, keep it warm for 24 hours, and then cool naturally to obtain water-soluble filled microcrystalline graphite particles.

[0036] A3. Vacuum filter the water-soluble filled microcrystalline graphite particles, and then dry them in an oven at a drying temperature of 110°C to obtain filled microcrystalline graphite particles.

[0037] A4. Put the filled microcrystalline graphite particles into ...

Embodiment 3

[0040] A1. Dissolve polyvinyl alcohol in deionized water, stir evenly to form a high molecular polymer solution, then pour the high molecular polymer solution into a hydrothermal reaction kettle filled with microcrystalline graphite particles, and mix well. Wherein, the mass ratio of polyvinyl alcohol, deionized water and microcrystalline graphite particles is 15:500:100. Preferably, the microcrystalline graphite is spherical microcrystalline graphite with a particle size of 11 μm, which is produced in Chenzhou, Hunan.

[0041] A2. Then heat the hydrothermal reaction vessel to 180°C at a heating rate of 5°C / min, keep it warm for 12 hours, and cool naturally to obtain water-soluble filled microcrystalline graphite particles.

[0042] A3. Vacuum filter the water-soluble filled microcrystalline graphite particles, and then dry them in an oven at a drying temperature of 130°C to obtain filled microcrystalline graphite particles.

[0043] A4. Put the filled microcrystalline graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com