Secondary battery winding pin and battery winding method employing the winding pin

A technology for secondary batteries and battery rolls, applied in secondary batteries, secondary battery manufacturing, circuits, etc., can solve problems such as waste of diaphragm, black, and increased curvature, so as to prolong service life, reduce production costs, and save raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

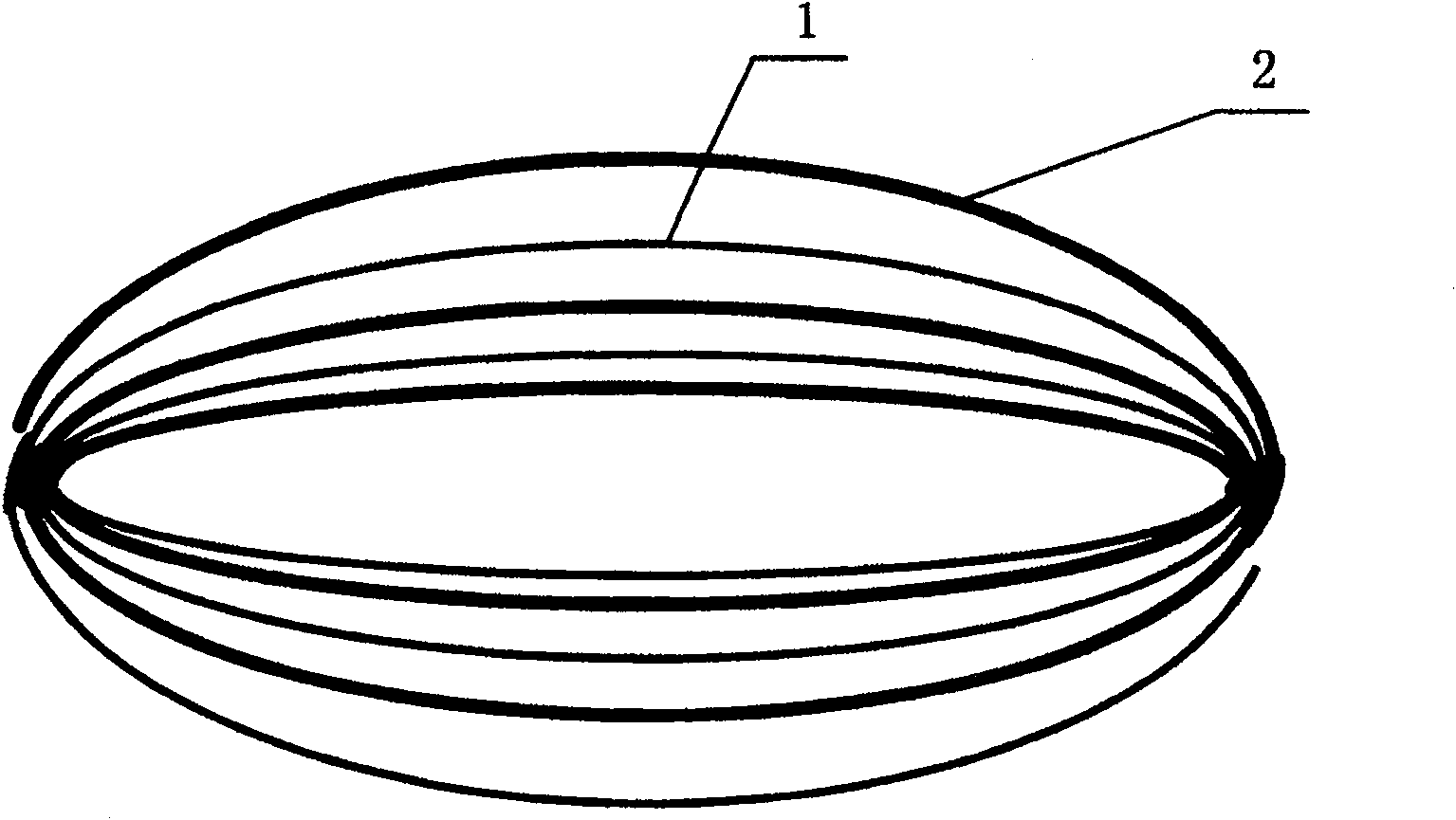

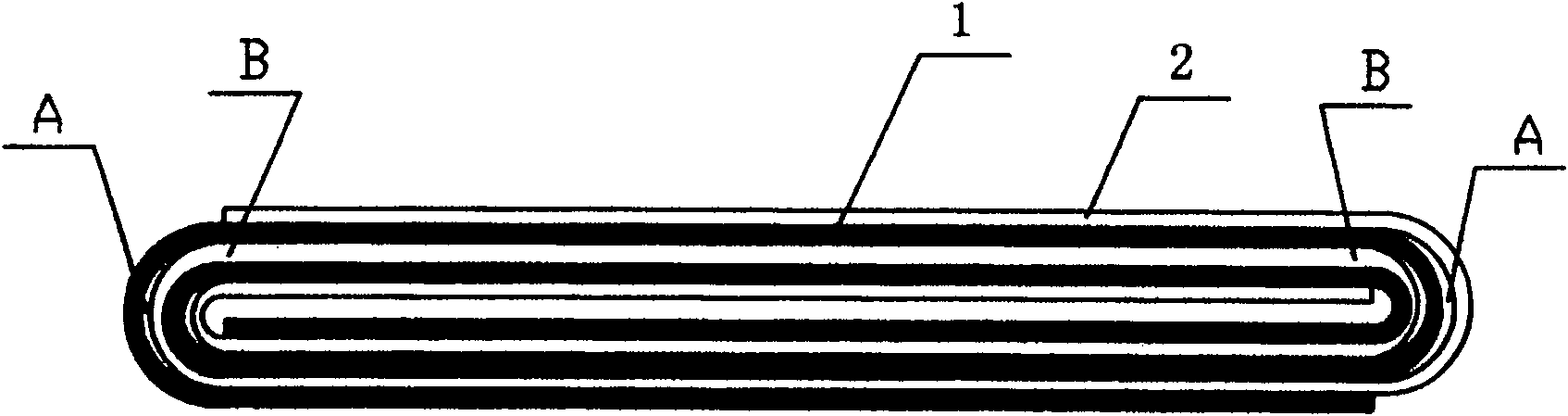

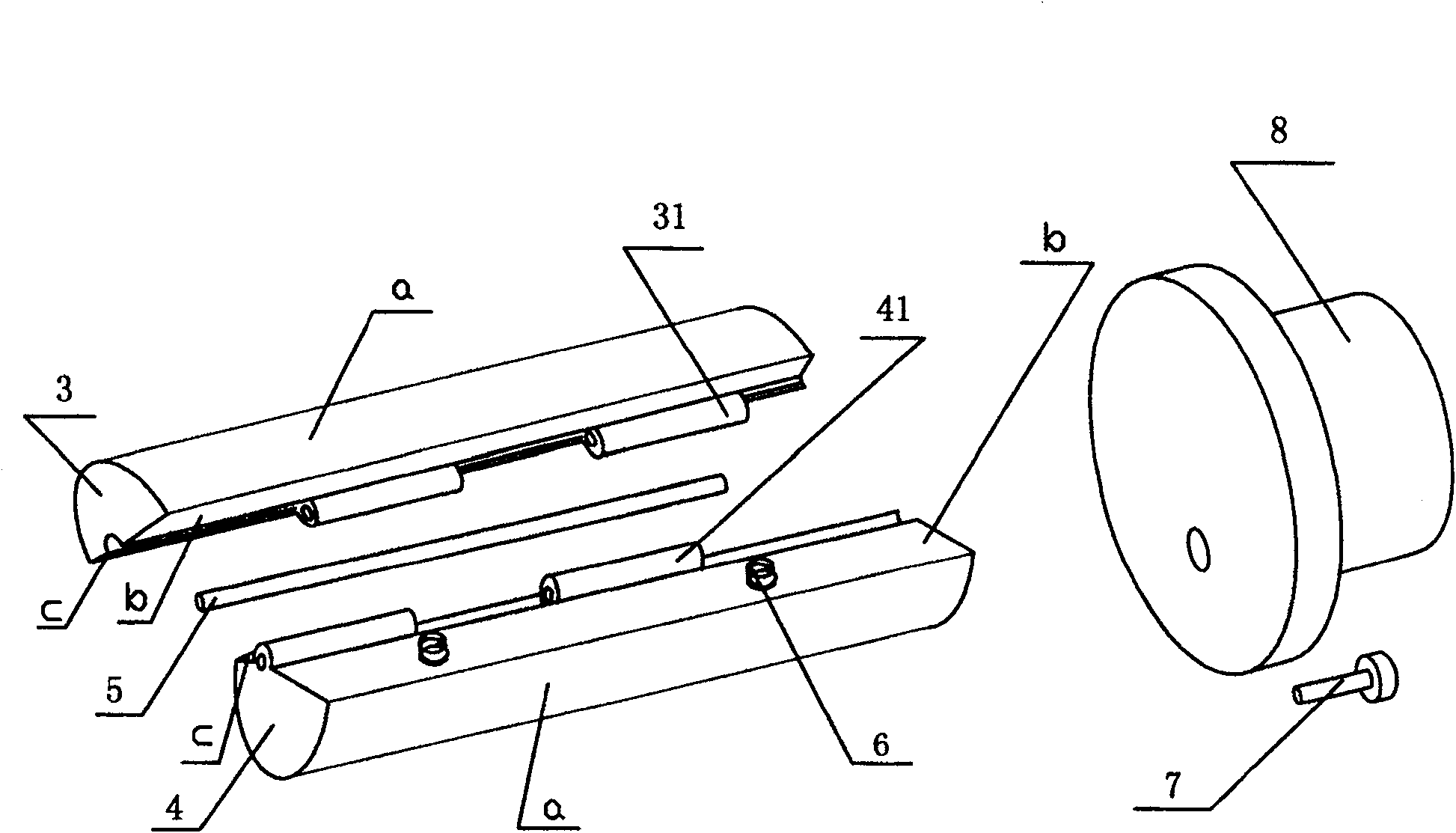

[0028] The secondary battery rolling pin of the present invention is mainly provided with a first member 3 and a second member 4, which are two roughly semi-cylindrical castings, wherein the first member 3 and the second member 4 are formed by arc surfaces a, The columnar body surrounded by the large inclined plane b and the small inclined plane c, the first member 3 and the second member 4 are respectively formed with pivot holes 31, 41 between the respective large and small inclined planes b and c, and the first member 3 When the large and small inclined surfaces b and c of the second member 4 are respectively opposite to the large and small inclined surfaces b and c of the second member 4, pivot shafts 5 are inserted in these pivot joint holes 31 and 41 to form a large jaw E and a small jaw F. A clip-shaped body with two jaws, the periphery of the clip-shaped body is in the shape of a cylinder as a whole. In addition, in the large jaw E formed by the large slope b of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com